Products

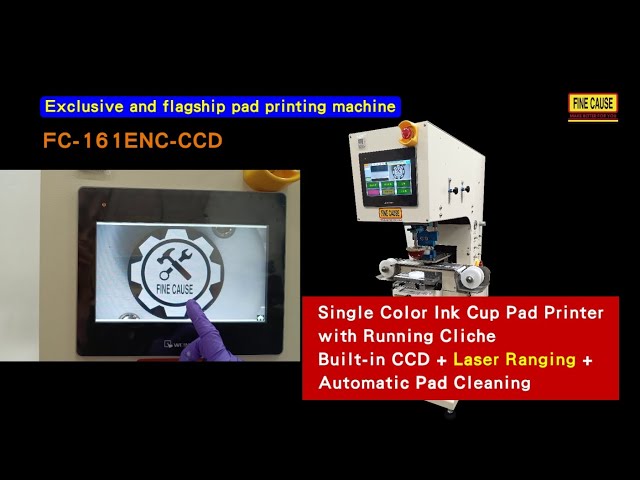

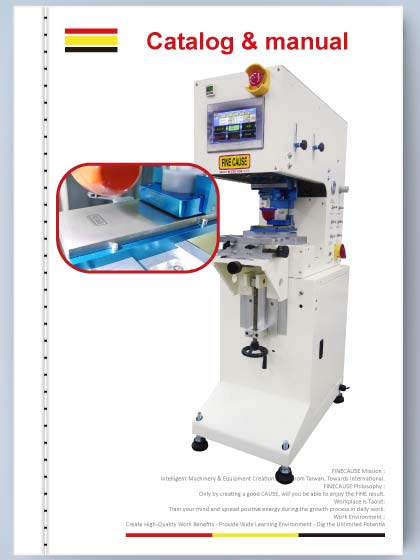

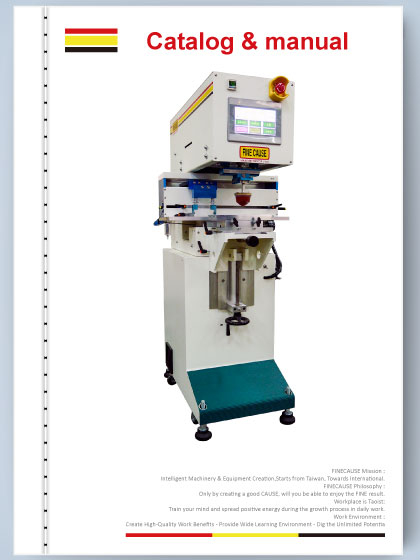

Single Color Ink Cup Pad Printer with Running Cliché (CCD + Laser Ranging + Automatic Pad Cleaning)

Single Color Ink Cup Pad Printer with Running Cliché (CCD + Laser Ranging + Automatic Pad Cleaning)

Product Info

The functions of CCD are:

-

The CCD imaging capture function allows for the immediate capture of printed products, enabling real-time debugging.

-

With an 8-megapixel CCD lens, printing quality is monitored in real-time and the images are saved to a USB flash drive automatically, providing traceability in your production process. Simultaneously, the images can also be displayed on the control panel for real-time inspection.

-

The CCD lens has built-in 2 sets of cross-line, ensuring precise alignment and effectively enhancing printing production efficiency.

-

The cross-lines are rotatable, offering greater convenience for alignment/adjustment in irregular shapes.

-

Image display on/off

-

Image pause

-

Image storage

-

Capture settings (manual capture once, automatic capture, number of automatic capture interval times, delay time before capture, delay time after capture, capture options before/during/after pad cleaning with immediate movement after capture and movement after image saving)"

-

-

Laser ranging function

-

-

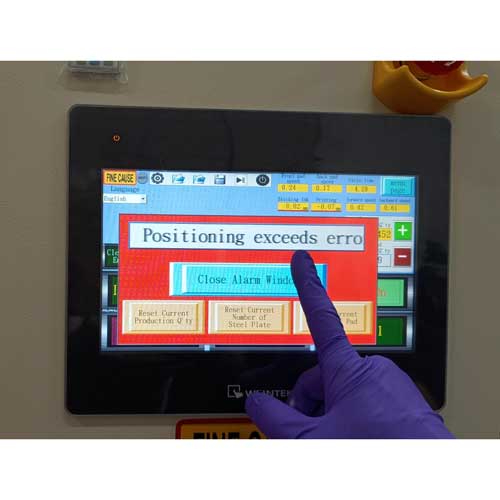

Ensure that each printing position is within the specified tolerance range.

-

The positioning tolerance can be set to automatically detect whether each printing is within the set range. If it exceeds, a warning screen and sound alert will be triggered.

-

Proximity switches are currently used in the market to confirm position arrival, but the machine will not trigger an alarm even if the error reaches 0.5mm! The precise laser detection in this machine guarantees accuracy in every printing position.

-

-

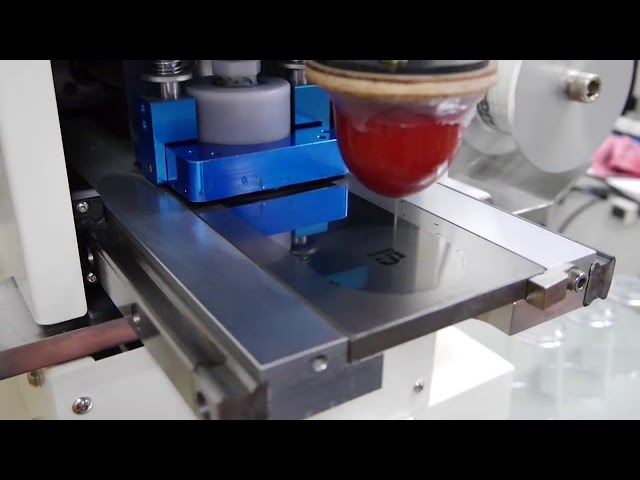

Automatic pad cleaning mechanism - automatically remove residual ink on the printing pad; the best helper to maintain high-quality printing.

-

Remove residue ink on the printing pad after a certain number of prints cam be set; and the cleaning number of times can be set as well.

-

- With pressure-regulating ink scraping system (patent no. M311585), the scraping pressure of the ink cup can be adjusted easily.

-

The pad printer is made by sheet metal + powder coating and the main body is formed integrally (patent number M453283).

-

Bushing component sets make the machine run more smoothly and stably and improve the printing quality greatly.

-

The cliché moves forward and backward to save space.

-

Extension of automated production line functionality! It can be flexibly integrated with existing production lines to expand printing modules, so that printing and quality QC can be completed in one go. (Compatibility confirmation with the equipment must be done prior to integrating with the production line mechanism).

10.0" color TFT big touch screen.

-

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

With abnormal alarm display, it is convenient for production line personnel to eliminate abnormalities quickly.

-

With electronic air pressure sensing, the device will notice automatically for insufficient air pressure.

-

The printing pad usage count and cliché usage count can be set. When the set value is reached, the device will stop and notice automatically.

-

CCD image projection technology enables real-time monitoring of printing results with a clearer view on large screen for inspection.

-

Built-in 5 languages, traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

- Utilizing programmable logic controller (PLC) for easy addition or modification of functions:

-

Pneumatic cylinder running speed is displayed on the screen.

-

Multiple groups of recipes can be stored and parameters can be set.

-

- Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

New paradigm of smart factories/Industrial Internet of Things (IoT)

-

With WIFI function, wherever you are, you can view the productivity report by downloading the FineCause APP.

-

Specifications

| Model/Specification | FC-161ENC-CCD |

|---|---|

| Single Color Ink Cup Pad Printer with Running Cliché Built-in CCD + Laser Ranging + Automatic Pad Cleaning |

|

| Machine Size (cm) | L:85 W:69 H:146 |

| Air Pressure (kg/cm2 psi) | 4~6 |

| Power Consumption (a) | 3 |

| Voltage (v) | 110V or 220V |

| Platform Size (mm) | 80*220 |

| Suggested Max. Printing Size (mm) | Ø50 |

| Tape Width for Ink Removal from Pad (mm) | 100 |

| Max. Height of Printed Object (mm) | 180 |

| Ink Doctoring Stroke (mm) | Fron and Back 120 |

| Height from Pad Holder to Cliché (mm) | 161 |

| Cliché Size in Use (mm) | 90*200 & 120*240 |

| CCD Lens | 8 Million Pixels |

Videos

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

Single Color Ink Cup Pad Printer with Running Cliché (CCD + Laser Ranging + Automatic Pad Cleaning)-FC-161ENC-CCD

Single Color Ink Cup Pad Printer with Running Cliché (CCD + Laser Ranging + Automatic Pad Cleaning)-FC-161ENC-CCD

-

FC-161ENC Mobile Platform Monochrome Ink Cup Pad Printing Machine - Operation Video

FC-161ENC Mobile Platform Monochrome Ink Cup Pad Printing Machine - Operation Video

-

FC-161ENC Mobile Platform Monochrome Ink Cup Pad Printing Machine (with cleaning mechanism) 2018

FC-161ENC Mobile Platform Monochrome Ink Cup Pad Printing Machine (with cleaning mechanism) 2018

-

FC-161ENCRunning Steel Plate Single-Color Ink Cup Pad Printer/pad printing machine

FC-161ENCRunning Steel Plate Single-Color Ink Cup Pad Printer/pad printing machine

Downloads

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

Pad printing technology

Pad printing technology

Pad printing technology

-

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

FC-161CNC-Horizontal scraping single-color ink cup pad printer

FC-161CNC-Horizontal scraping single-color ink cup pad printer

FC-161CNC-Horizontal scraping single-color ink cup pad printer

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links