Reference

Pad printing technology

| Filename | About pad printing.pdf |

| File Size | 687.8KB |

| Revision Date | 2024/09/03 |

■ About the new trend of pad printing/pad printing technology

The relationship between pad printing and printing (pad printing principle):

Pad printing is a kind of intaglio. The ink is covered on the cliche; then use a blade to scrape off the ink on the surface. The printed pattern is the part where the ink is left in the etched area. Then use a printing pad to pick up the ink and transfer to the object. There are various materials can be printed, such as plastic casing, metal and high technology related products, etc. Compare with screen printing, pad printing is more suitable for printing small areas, thin lines, and concave and convex surfaces.

The after-printed ink thickness of pad printing is much thinner than screen printing. Most pad printing cliche depth is set at 0.025mm. But if you use the pad printer with thermostatic system, the cliche depth can be adjusted to 0.035mm and the ink temperature can be raised during printing, promoting the volatilization speed during ink transferring in order to achieve complete ink deposit. Moreover, 【the ink opacity will be improved greatly】, reaching the ink thickness that cannot be achieved in past pad printing.

🔥 Stable ink temperature and concentration are the keys to consistent print quality!Fine Cause redefines pad printing with smarter, more stable, and more efficient production technology.

If the printed object is very thin and light, the platform with suction function is recommended. Especially for those with large printing patterns.

-

Superstrength sealant is commonly used to make the aids because it is done fast and convenient. Other materials like melamine resin and epoxy can also be used.

-

No matter what kind of the printing methods used, it is very important to keep the objects horizontal.

-

If the printed pattern is very close to the edge of the object, it is the best to add a pedestal to avoid the center point of the pad hanging in the air. This may cause the deformation of the pattern.

-

If the printed object is soft, it is better to place a padding block underneath the printed object.

-

Depth of the pattern on the plate is from 5μm to 45μm. To print absorbent material such as cloth, paper, and ceramic, it is better to use a deeper steel plate. For 4-color screen dot manuscript, the depth is about 15μm-20μm. For general plastic and metal (thinner pattern), the depth is about 20μm-25μm. For thicker line pattern, the depth is about 28-35μm. The deeper the depth, the higher density (Fast-Dry) ink is needed.

-

Most of the people are using “Steel Plate” in the market. There are also aluminum plate, resin plate, and stainless steel plate used.

-

Surface of the steel plate – Normally, both plane grinding and emery grinding are applied. Sometimes, people only do the plane grinding to save the cost.

-

Size of the steel plate – Based on the machines and printed pattern sizes.

SKD11 Pad Printing Steel Plate - Used for pad printing, it has a long service life, typically offering hundreds of thousands of printing cycles. The thick steel plate ensures excellent scraping performance and outstanding image clarity. It features high wear resistance, good hardenability, and minimal deformation during quenching.

-

high abrasion resistance, excellent harden-ability and minimal quench stress

-

heat-treated steel plate - hardness can reach 58-62HRC

-

affordable price, high hardness and general use cold work dies for general use The steel plate is an alloy steel that contains high contents of carbide and chromium, so it has high hardness and appropriate

-

tenacity. This type of steel is also deemed as an air hardening steel because of process of tempering and hardening. It is one of the best wear-resistance alloy steels.

-

Molybdenum, vanadium and other elements are added, so it has the characteristics of wear-resistance, impact resistance and no deformation

-

After the second refining, the purity is good, and the grains are fine.

Pad Printing Cliche Plate Polishing/Carborundum Sandblasting

-

Carborundum: One of our best services is the steel plate sandblasting and polishing, plus we are pursuing the explicit quality for our premium services.

-

Carborundum is a type of synthetic SiC for the use as an abrasive. This material is well known by its hydrophilicity and durability.

-

Characteristics: the crystalline structure and self-sharpening effect makes the particles sharp and durable. High hardness and appropriate toughness. Even granularity leads to stable polishing quality.

-

Application fields: sandblasting, polishing, zinc plate polishing, stained glass sandblasting carving, etc. Mold, coated abrasives, friction pad mold, burr removing or flash removing, etc.

■ FINE CAUSE ink cup type pad printing machine steel plate size

60mm ink cup pad printing machine:

New 60mm ink-cup pad-printers use 200 mm L. x 90mm W. x 10mm thick steel plate.

Old 60mm ink-cup pad-printers use 180 mm L. x 90mm W. x 10mm thick steel plate.

90mm ink cup pad printing machine:

Uses 240mm L. x 120mm W. x 10mm thick steel plate

Attentions for Ink-cup style steel plate:

-

The direction of the manuscript and jig(aid) has to be the same.

-

The steel plate has to be “Emery Grinded”.

■ Commonly used steel plate sizes for ink tray pad printing machines are:

80*80 mm

80*95 mm

100*100 mm

110*140 mm

100*150 mm

lnk tray pad printing machines, precautions for using steel plate:

-

A. Left and right side of the steel plate have to be 15mm more than the printed pattern. Front and back side of the steel plate have to be 20mm more than the printed pattern. It is more convenient to use.

-

B. If there is long line pattern, make sure that the pattern is not paralleled the scraping device to avoid falling into the gap.

Pad printing machine ink cup

There are 3 sizes of the ink-cup: 60mm D, 90mm D, 130mm D

When designing the pattern, make sure that the size is 5mm less than the ink-cup’s daimeter.

Economic type of ink cup/Pad printing ink cups

Economic type of ink cup - very cost effective

Easy cleaning

The ink cup is a closed container, which prevents the ink from quickly evaporating during printing, saves ink, and improves production efficiency.

60Ø ink cup

90Ø ink cup

130Ø ink cup (silver)

Pad Printing Machine Disposable Ink Cup(Utility Model Patent No. M648875.)

-

The ink cup is for one-time use and can be thrown away after use. There is no need to wash the ink cup, which saves cleaner.

-

What sets it apart from conventional ink cups is 【the absence of sealing rings】, 【making disassembly and replacement easier】.

-

No need for the use of a sealing ring, but it ensures no ink leakage.

If distinguishing ink by drying methods, there are 3 kinds - Solvent Evaporation, UV Dry, and Water-Based inks.

-

Solvent Evaporation Ink – The drying speed depends on the ignition point of the solvent. The higher the ignition point, the slower the evaporation of the solvent. For faster evaporation speed, it is better to use in pad-printing. When printing, the ink has to be halfway dry to enable deinking.

-

UV Drying Ink – The drying of the ink depends on UV light. Although there is UV ink specially made for pad-printing in recent years, the outcome is still not better than using solvent-evaporation ink.

-

Water-Based Ink – It evaporates and dries naturally. You can speed it up by using an oven. This kind of ink used in pad-printing is normally for special industries like ceramics and contact lenses.

There are many different materials for the printed objects; each object has its own adherence condition; therefore, there are many different brands of ink, and each brand has many different series to meet the printing requirements.

1.Ruco

2.Marabu

3.Seiko

4.Japan Ops

1. Ruco (FINE CAUSE exclusive agent) : It evaporates quickly and is suitable for pad printing. There are also series suitable for screen printing.

-

110GK series: Suitable for glass, varnished surfaces, metals, thermosetting plastics, polyamide (PA), polycarbonate (PC), pre-treated polyethylene (PE) and polypropylene (PP).

-

T45 series: suitable for ABS, PC, acrylic.

-

T200 series: Suitable for metal and baking paint.

-

T01 Series: Suitable for glass, varnished surfaces, metals, thermosetting plastics, polyamide (PA), polycarbonate (PC),pre-treatedpolyethylene(PE)andpolypropylene(PP).

RUCO Hardener Series

2. MARABU (Germany): Moderate evaporating rate. Suitable for both pad and screen printing

SR Series: Suitable for ABS, PC, Acrylic (Adding hardener is optional)

PU Series: Suitable for PU material like golf balls (Hardener is a must)

PY Series: Suitable for Metal, Coating, IC, Memory Card (Hardener is a must)

GL Series: Suitable for Glass material (Hardener is a must)

3. SEIKO (Japan):Moderate evaporating rate. Suitable for both pad and screen printing

-

EPOXY1300 Series: Used on metal, coating and glass. Need high tempture baking at 170 degree/30minutes to adhere the ink on object.

-

EPOXY1000 Series: Used on metal, coating and glass. Need high tempture baking at 120 degree/30minutes to adhere the ink on object. (Hardener is a must)

-

VIC Series: Used on ABS, PC, Acrylic (Hardener is optional)

4. OPS (Japan) : Moderate evaporating rate. Suitable for both pad and screen printing

OPS Series : Suitable for PP material (Such as Syringe). Not ALL PP material is workable. Best to test it first.

※ Find Cause WK: Moderate evaporating rate.

Suitable for both pad and screen printing. Suitable for ABS, PC, Acrylic

-

The thinner the pattern is, the sharper/harder rubber pad is used.

-

The closer the ink is to the center of the pad, the better the exhaustion is.

-

When the new pad has poor ink absorption, you may use alcohol to clean the pad surface.

-

The deinking effect is the best when the pad ink is at semi-dry state. The deinking process can be done successfully more than 10,000 times per day.

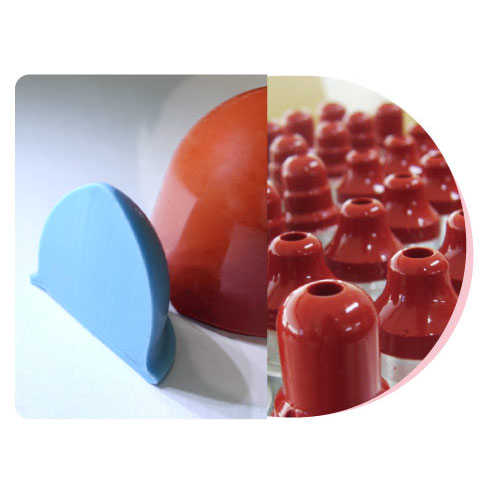

■Silicone Colors

Silicone Pad Printing Pads Hardness Guide (Click here to request a free copy)

| ★Excellent ●Good △Average X None | |||||

|---|---|---|---|---|---|

| Silicone color | Ink absorbency | Solvent resistance | Ink deposit | Anti-static | Extensibility |

| Blue | △ | ★ | △ | X | △ |

| Red | ★ | ● | ★ | X | △ |

| White | ★ | △ | ● | X | ★ |

| Pink | ★ | △ | △ | ★ | ● |

| Grey | ★ | △ | ★ | X | ● |

Silicone Colors

Generally, we use different colors to distinguish pads’materials.

-

Blue: Excellent solvent resistance and stronger toughness extend the lifespan of the pads, making it suitable for high-volume printing

-

Red: Excellent ink absorption and deposit, suitable for use on prints with poor ventilation and textured surface substrates.

-

White: Excellent flexibility, suitable for use with soft pads, less prone to damage when covering irregular substrates.

-

Pink: It possesses anti-static properties and excellent ink absorption, allowing for the complete presentation of fine fonts.

-

Grey: Excellent ink absorption and deposit, minimal feathering on fine fonts, and excellent saturation.

The percentage displayed on the hardness scale of Finecause printing pads catalog is a reference to the proportion of added silicone oil. The actual softness or hardness may vary depending on the quality and size of the printing pads.

For example:

For large printing pads, with 40% silicone oil content, the hardness tends to be harder. For small printing pads, with 40% silicone oil content, the hardness tends to be softer.

■ Operation Steps (Ink-Cup Style)

Prepare all the materials:1. Steel Plate 2. Rubber Pad 3. Ink 4. Solvent 5. Jigs 6. Printed Object.

Pour the ink into the ink-cup and add the thinner (about 20%).

For RUCO ink/Thin Line/Steel Plate Depth 20μm-22μm: Use standard or fast evaporating solvent.

For MARUBU or WK Ink/Thin Line/Steel Plate Depth 20μm-22μm: Use fast evaporating solvent or extra- fast evaporating solvent.

For RUCO Ink/Steel Plate Depth 25μm-28μm: Use fast evaporating solvent or extra-fast evaporating solvent.

For MARUBU or WK Ink/Steel Plate Depth 25μm-28μm: Use extra-fast evaporating solvent.

For MARUBU or WK ink/Steel Plate Depth 25μm-28μm, if using extra-evaporating solvent and still cannot deink completely, use the dryer on ink before printing.

If this is still not working, try placing the ink for some time to evaporate the slow-dry ingredient inside the ink and then add the extra-fast evaporating solvent.

■ Solutions to Printing Defects

Q1. Incomplete printed pattern

-

Check the pattern on the steel plate to see if it is complete.

-

Check the ink to see if it is too thick. If yes, the small/thin pattern may not be printed out.

-

Check the ink to see if it is drying too fast. If yes, the small/thin pattern may not be printed out.

-

Set the time before sticking the ink to 0.

-

When the pad compression speed is too slow, it will cause the ink to dry. Thus, the pad is unable to pick up the ink.

-

Bad ink absorption by the pad. When this happens, not all of the pattern can be printed out, and some areas will be missing.

Q2. The printed pattern is complete, but ink-drawing (no direction) occurs.

-

Use adhesive tape to clean the pad and try to print again.

-

If the ink-drawing still happens, it is very likely that the ink is too sticky.

-

a. Add thinner under the circumstances of no overflow ink.

-

b. Add ST1 extender base to reduce the ink viscosity.

-

c. Reduce the speed of lifting the rubber pad.

Q3. Ink-Drawing (Along the direction of scraping ink)

-

Ink is not scrapped cleanly – Adjust the scraping ink pressure on the right side.

-

Take off the ink-cup and check the cup blade with your nail to see if it is damaged.

-

Scraping ink on the steel plate for more than 150K – 200K times will result in unclean situations.

Q4. Overflow Ink

-

Ink is too thin.

-

Rubber pad is too hard.

-

Scraping ink on the steel plate for more than 150K – 200K times will result in unclean situations.

Q5. Bad Exhaustion (Pinholes on the end of the printed line)

-

Use a sharper/harder rubber pad.

-

Reduce the speed of pad compression.

-

Print on adhesive tapes 20~30 times before printing on your object.

Links

Links