Products

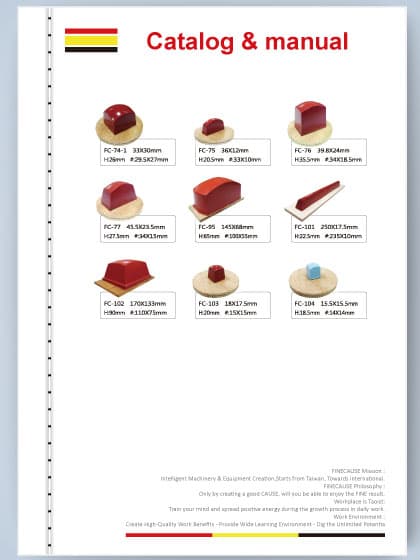

Catalog of Printing Pads (for free)

Catalog of Printing Pads (for free)

Product Info

-

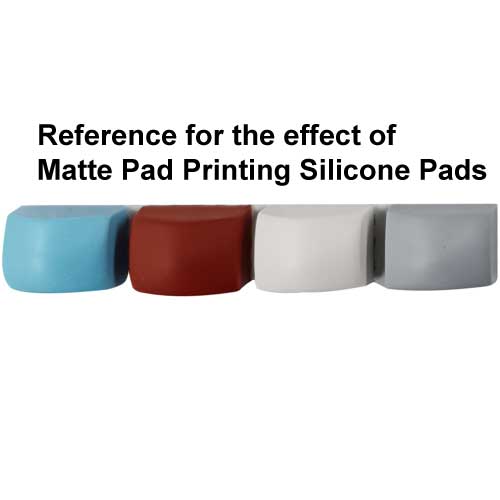

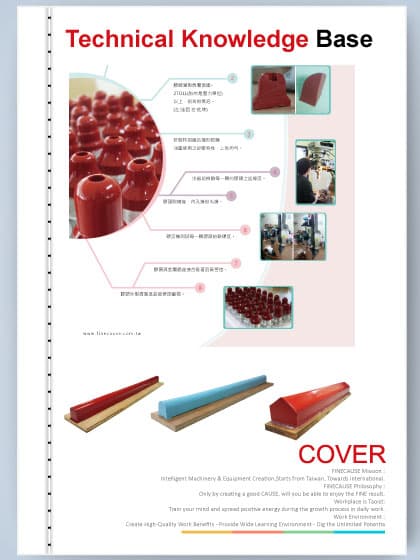

The respective suitability of printing pads are generally displayed in different colors of silicone.

-

We provide a variety of printing pads for different industries in pad printing.

-

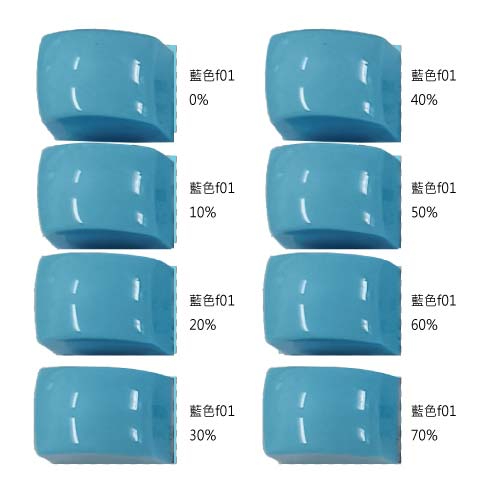

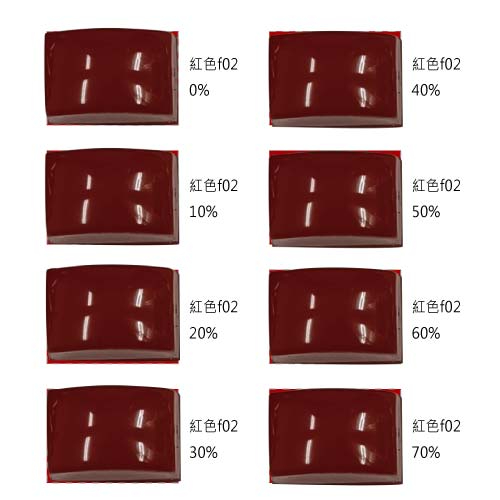

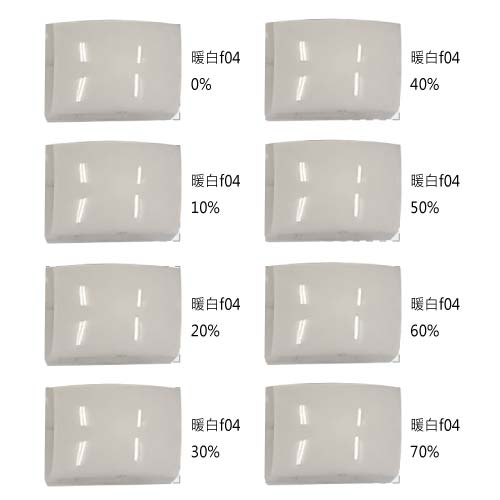

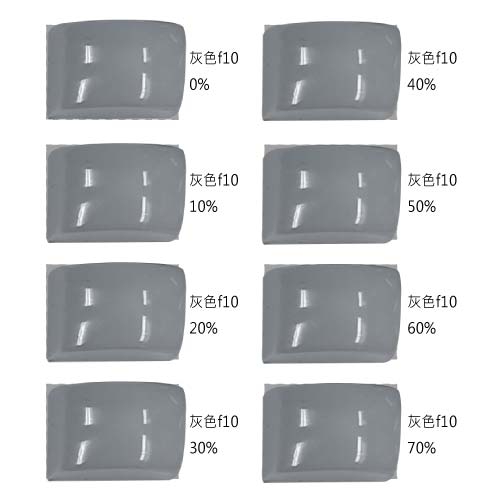

Hardness: 0%-70%, physical catalog allows you to touch and preset the preferable hardness of printing pad before ordering. It also saves your time on looking for the appropriate pad and increases productivity and yield rate.

-

Red pad: High hardness, good ink absorption, suitable for printing non-bubble images and processing on textured surfaces.

-

Blue pad: good solvent resistance; suitable for mass production due to long range of use

-

White pad: good flexibility; available for making softer pads; good ink pick-up

Profiles and Sizes of Printing Pad

-

Normal solutions based on cliché image size and design

-

For pad printing multiple fine lines of a cliché image, the better solutions are types of V-shape profiles.

-

For pad printing bigger dimension of a cliché image, the better solutions are softer, bigger and flat profiles.

-

For pad printing multiple indivisual cliché images, the better solutions are cluster profiles to keep better print job.

-

When pressing a printing pad, the print job may not be applicable after reaching a certain level. Therefore, when selecting the type of printing pad according to the printing size, do not choose one too small unless there is interference next to the printed object.

-

When using a harder printing pad, speed of ink pick-up should be faster than velocity of flow to keep away from flooding.

-

In some cases, there are air bubbles in printing ink, the better solutions are using harder pad to help removing bubbles when printing.

Ink Absorption of Printing Pad

-

The better solvent-resistance, the worse absorption.

-

New printing pads will run a much better print job after a few use.

-

Pretest printing and confirm opacity of the ink. When a printing pad is not applicable to completely absorb the ink under a noraml range of volatile rate, use dry cloth to dip some detergent (e.g. ethanol or cliché detergent), and apply onto the surface of pad.

-

Though wiping the surface of printing pad may help the ink absorption, it may reduce the ink deposit at the same time.

-

Note that longer down time may cause dried ink on cliché plate and lead to incomplete print job.

Ink Deposit of Printing Pad

-

After running the peak of the usage, the longer term of use, the worse ink deposit because of continuous corrosion and friction on the surface of pad.

-

The faster volatilization, the better ink deposit (note that incomplete print job may result from short volatile speed; pretest beforehand)

-

After picking up the ink, hold the ink for 0.3-1.5 seconds before ink transfer. As aforesaid, this act makes the ink a bit drier and lead to better ink deposit. Especially adding an external drying method, e.g. a hair dryer, can improve the print job (this is suitable for lower temperature environment.)

-

The picked up ink provides the best timing of ink deposit and can continuously operates more than 10000 prints a day.

-

Basically complete ink deposit every print

Specifications

| ★Excellent ●Good △Average X None | |||||

|---|---|---|---|---|---|

| Silicone color | Ink absorbency | Solvent resistance | Ink deposit | Anti-static | Extensibility |

| Blue | △ | ★ | △ | X | △ |

| Red | ★ | ● | ★ | X | △ |

| White | ★ | △ | ● | X | ★ |

| Pink | ★ | △ | △ | ★ | ● |

| Grey | ★ | △ | ★ | X | ● |

Features of Matte Pads

Blue Excellent solvent resistance and stronger toughness extend the lifespan of the pads, making it suitable for high-volume printing

Red Excellent ink absorption and deposit, suitable for use on prints with poor ventilation and textured surface substrates.

White Excellent flexibility, suitable for use with soft pads, less prone to damage when covering irregular substrates.

Pink It possesses anti-static properties and excellent ink absorption, allowing for the complete presentation of fine fonts.

Grey Excellent ink absorption and deposit, minimal feathering on fine fonts, and excellent saturation.

The percentage displayed on the hardness scale of Finecause printing pads catalog is a reference to the proportion of added silicone oil.

The actual softness or hardness may vary depending on the quality and size of the printing pads.

For example:

For large printing pads, with 40% silicone oil content, the hardness tends to be harder.

For small printing pads, with 40% silicone oil content, the hardness tends to be softer.

| Comparison of 【Printing Efficiency】 between Two Types of Pads | ||||

|---|---|---|---|---|

| Pads model FC-21, red, 40% | Test date: January 18, 2024 | |||

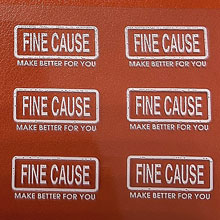

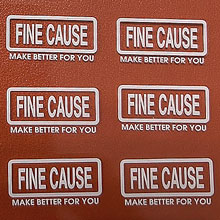

| The freshly printed | Zoom in on a specific area | After printing 50 times | Notes | |

| Normal (Glossy) |  |

|

|

|

| Feature: Due to the pad's softness, there is poor ventilation within the pattern, resulting in a more severe of holes. | ||||

| (In the past, wiping the pads or printing over 50 times would gradually reduce the holes). | ||||

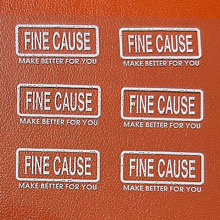

| The freshly printed | Zoom in on a specific area | After printing 50 times | Notes | |

| Matte |  |

|

|

|

| Feature: Due to the Normal pads' softness leads to inadequate air exhaust for the pattern, while matte pads reduce holes by over 80% compared to glossy pads. (ink absorption +80). | ||||

| 【New pads】does not require wiping to improve ink absorption. | ||||

Videos

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Instructions - Ink Cup Installation

Instructions - Ink Cup Installation

-

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

Downloads

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

Finecause - Characteristics of Contact Lens and Rubber Pads

Finecause - Characteristics of Contact Lens and Rubber Pads

Finecause - Characteristics of Contact Lens and Rubber Pads

-

Contact lens rubber pad

Contact lens rubber pad

Contact lens rubber pad

-

RUCO inks - T200 M series DM

RUCO inks - T200 M series DM

RUCO inks - T200 M series DM

-

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links