Products

Cam Type Bottle Screen Printing Machine

Cam Type Bottle Screen Printing Machine

Product Info

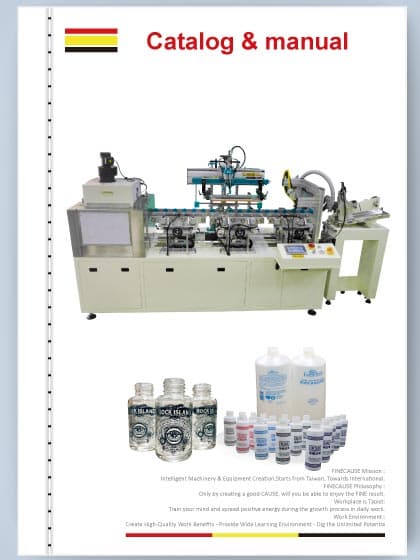

FA-LV4 Cam Type Bottle Screen Printing Machine

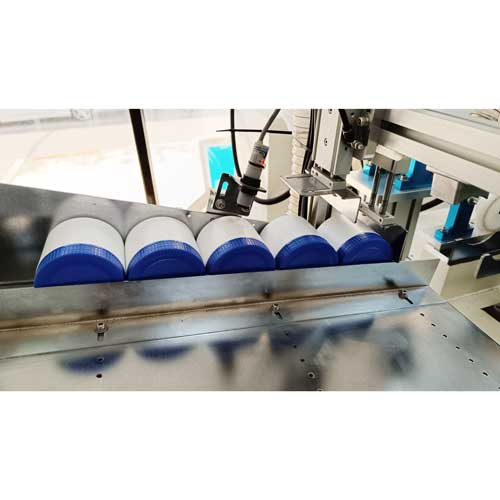

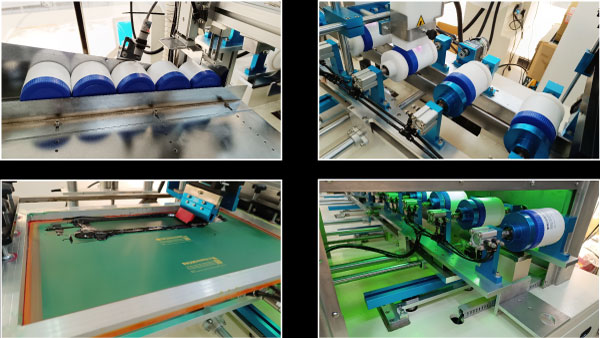

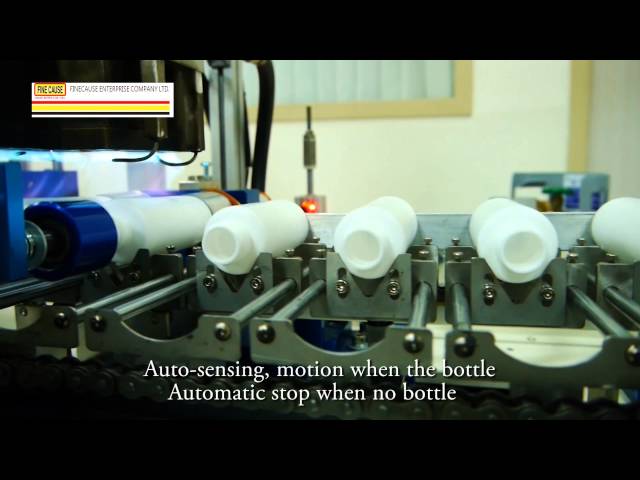

Object feeding mechanism:

-

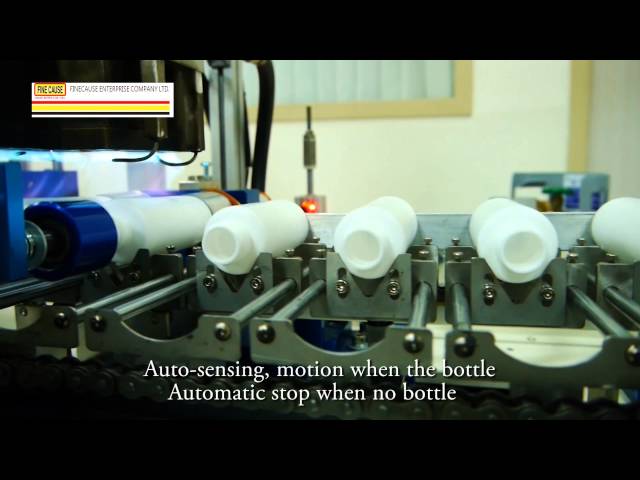

The automatic bottle printing machine is equipped with a ramp mechanism for objects feeding. The mechanism and program are modular. 1 to 6 colors can be connected in series. A fully automatic feeding system can be combined as well.

-

The automatic bottle printing machine is equipped with a ramp mechanism and a suction arm, coupled with a feeding sensor for objects feeding. It precisely and rapidly grabs objects, enhancing stability and preventing dropping or object jams.

Corona pre-treatment:

-

This bottle printing machine is equipped with a corona treater for automatic pre-treatment; a flame treatment machine can be applied for pre-treatment as well.

Cam disk mechanism:

-

【Cam disk】 mechanism is used; the cam operation is driven by servo motor continuously. The operation runs 【stably and fastly】, increasing production speed.

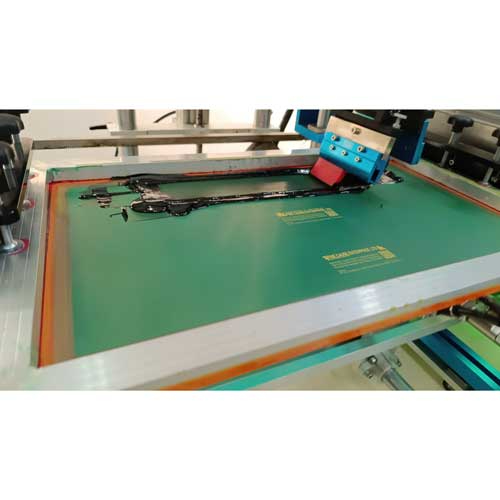

400-stroke screen printing machine:

-

Pneumatic squeegee assembly up and down linearly.

-

Equipped with magnetic squeegee clip - Patent No. M390871, allowing convenient disassembly, assembly, and adjustment of the squeegee. Suitable for plain, S cut, D cut squeegee; the tilting angle can be adjusted freely during printing to adapt to containers with insufficient roundness.

-

UV curing mechanism:

-

After printing, rapid curing are achieved through UV light exposure.

Smart HMI

-

The bottle printing machine is equipped with a 7.0" color TFT touchscreen and PLC. It features automatic alarms for abnormalities and insufficient air pressure with a marquee display.

-

The usage times of screen stencil can be set; when the set value is reached, the machine will automatically stop and alarm.

-

Built-in 5 languages, including Traditional Chinese, English, Thai, Vietnamese, and Indonesian. Switching between them is just one click away.

-

Built-in smart bar chart that the productivity, operation time, production speed, and more in the past 30 days can be shown.

-

-

With WiFi functionality, download the FineCause app, and you can view production reports from anywhere, assisting you in achieving production management goals.

- Actual printing production speed: 1,850 pcs/h. The printing area does not affect the production speed of this machine.

-

The bottle printing machine is suitable for round bottles with a diameter of 40 to 80mm and a length of 55 to 300mm. The machine can be designed according to the size of the bottles.

-

Automatic discharge - Automatically discharges after curing. It can also be paired with discharge methods such as a conveyor belt.

Specifications

| Model/Specification | FA-LV4 |

|---|---|

| Printing Color | Series connection 1~6 colors |

| Air pressure (kg/cm2 psi) | 4~6 |

| Power Consumption (a) | 7A |

| Voltage (v) | 220V / 3 Phase |

| Max. Printing Area (mm) | Bottle Diameter 40~80mm, Height 55~300mm Machine can be customized according to bottle size. |

| Machine Size (cm) | L:250 W:108 H:171 cm |

| Productivity/Hour | 1850 pcs |

| Net Weight | 1200 kg |

Videos

-

FA-LV3 Automatic monochrome curved bottle printing servo screen printer (flame+UV curing)

FA-LV3 Automatic monochrome curved bottle printing servo screen printer (flame+UV curing)

-

FA-LV1 Automatic Monochrome Curve Screen Printer Special for Silicone Filling Hose

FA-LV1 Automatic Monochrome Curve Screen Printer Special for Silicone Filling Hose

-

FA-LV1-KL Automatic Monochrome Curved Screen Printer

FA-LV1-KL Automatic Monochrome Curved Screen Printer

-

FA-LV1 Automatic Monochrome Curved Screen Printing Machine (Bottle Printing Machine)

FA-LV1 Automatic Monochrome Curved Screen Printing Machine (Bottle Printing Machine)

-

Cam Type Bottle Screen Printing Machine-FA-LV4

Cam Type Bottle Screen Printing Machine-FA-LV4

Downloads

-

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

-

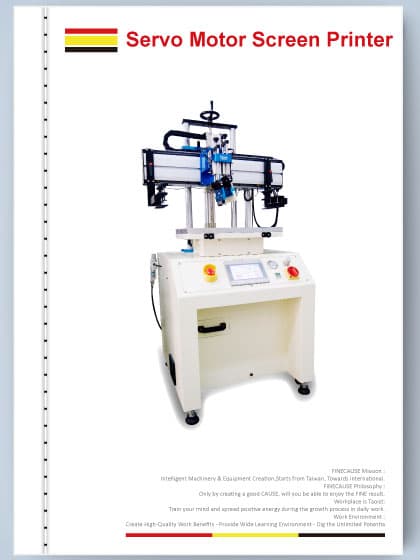

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

-

Unitex Squeegees

Unitex Squeegees

Unitex Squeegees

-

Introduction of Italian SERITEC DM

Introduction of Italian SERITEC DM

Introduction of Italian SERITEC DM

-

The relationship between screen printing and printing

The relationship between screen printing and printing

The relationship between screen printing and printing

-

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links