Products

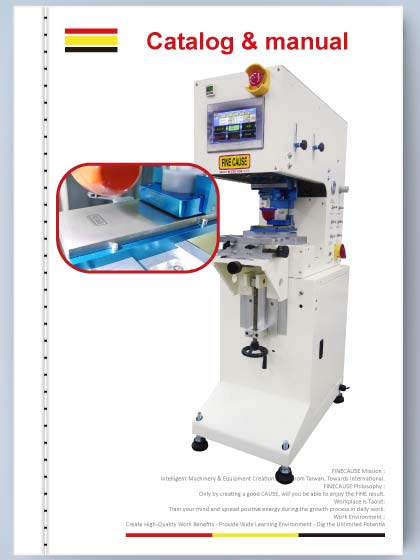

Pad Printer by Horizontal Scraping Type - 5 sets of Independent Printing Pad with Cylinders

Pad Printer by Horizontal Scraping Type - 5 sets of Independent Printing Pad with Cylinders

Product Info

Ink Cup Pad Printer by Horizontal Scraping Type - 5 sets of Independent Printing Pad with Cylinders + Servo Slide and Rotation-FC-161CNC-YC

▇ Feature:

-

With pressure-regulating ink scraping system (patent no. M311585), the scraping pressure of the ink cup can be adjusted easily.

-

The pad printer is equipped with 5 sets of independent cylinders that can be controlled individually.

-

It is possible to freely set the printing station and change the printing sequence as desired.

-

It is possible to freely set the printing times of each station.

-

-

The ink cup of the pad printer adopts a left-to-right horizontal movement.

-

Equipped with a servo slide table and servo rotation mechanism, allowing for fine tuning of the jig angle to accommodate printing angles according to the object.

-

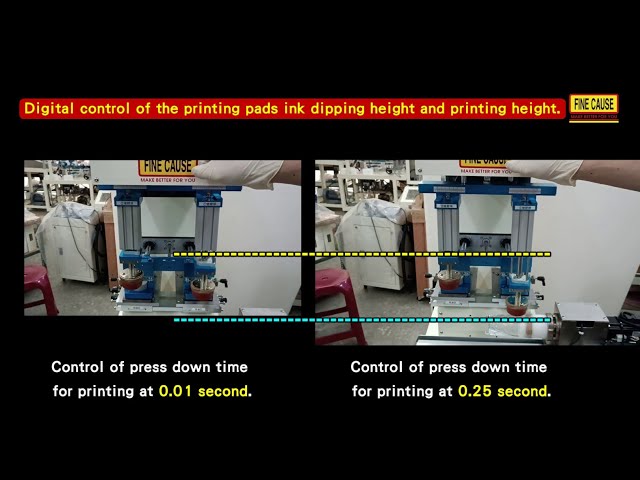

Digital control of the ink dipping height and printing height of the printing pads ensures accurate and easy operation.

-

It can be set to have the independent cylinder and printing pad extend first, facilitating precise alignment for the operator during printing.

-

The printing pad with pneumatic cylinders of two-stage downward pressure is designed to cater to custom requirements for special-shaped object.

-

7.0" 65536 color TFT touch screen:

-

Adopt PLC, which is easy to add or modify functions.

-

Built-in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese,and Thai.

-

Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With smart factory Industrial Internet of Things (I.O.T.), wherever you are, you can view the productivity report by downloading the FineCause APP.

-

▇ Action Process:

-

Manually place the object on the rotating jig.

-

The servo slide table moves to the first printing position, and the printing pad presses down to perform the printing.

-

The servo slide table moves to the front of the second logo on the cliché, and the servo rotation mechnism rotates the object to the second printing position. Then, the printing pad presses down to perform the printing.

-

The servo slide table moves to the front of the third logo on the cliché, and the servo rotation mechnism rotates the object to the third printing position. Then, the printing pad presses down to perform the printing.

-

The servo slide table moves to the front of the forth logo on the cliché, and the servo rotation mechnism rotates the object to the forth printing position. Then, the printing pad presses down to perform the printing.

-

The servo slide table moves to the front of the fifth logo on the cliché, and the servo rotation mechnism rotates the object to the fifth printing position. Then, the printing pad presses down to perform the printing.

-

The servo slide table transfers the rotating jig back to the first station position.

-

Manually remove the object.

Specifications

| Model | FC-161CNC-YC |

|---|---|

| Printing Color | 1 |

| Pneumatic Cylinder for Printing Pad | 5 sets (Can be customized according to requirements.) |

| Suggested Max. Printing Area | Each set Ø50 |

| Suitable Cliché Size | 590*80 mm |

| Productivity / Hour | 1200~1800 pcs |

| Machine Size | L: 95 W: 80 H: 150 cm |

| Net Weight | 130 kg |

Videos

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)-FC-192ACC-CX

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)-FC-192ACC-CX

-

FC-194DCC-CX-4 Color Ink Cup Pad Printer by Servo Sliding Table

FC-194DCC-CX-4 Color Ink Cup Pad Printer by Servo Sliding Table

-

FC-164DCC-SD Four-color Servo Pad Printer

FC-164DCC-SD Four-color Servo Pad Printer

Downloads

-

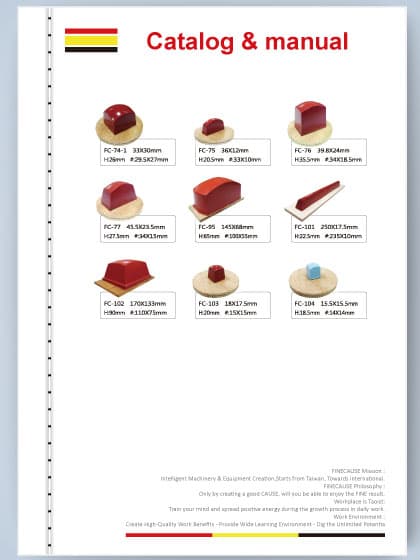

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

-

RUCO inks exclusive agent certificate

RUCO inks exclusive agent certificate

RUCO inks exclusive agent certificate

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links