Products

Fully Automatic Screen Printer(Printing for Magnetic Stripe Coating)

Fully Automatic Screen Printer(Printing for Magnetic Stripe Coating)

Product Info

FA-300TSN-XQ-2 Fully Automatic Screen Printer(Printing for Magnetic Stripe Coating)

-

The fully automatic screen printer is equipped with a 10" HMI.

-

The large color panel is easy to operate. Language can be English, Indonesian, Vietnamese, Thai, Chinese or customized.

-

Enter the formula parameter page to store 100 sets of formula.

-

-

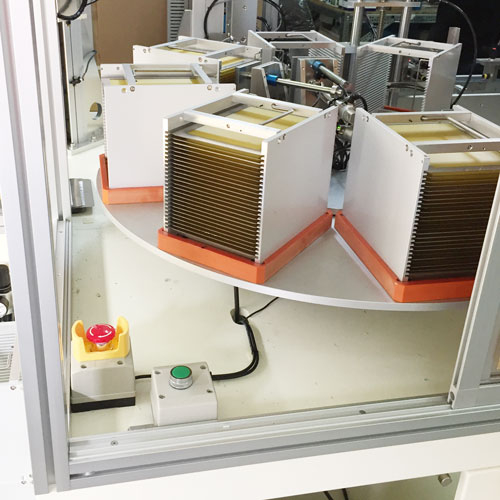

Feeding mechanism by carousel.

-

8 stations is on indexing table. Up to 200 pcs of object can be placed at a time.

-

The same batch of the objects can be set to any quantity. After feeding, it can be replenished at any time.

-

-

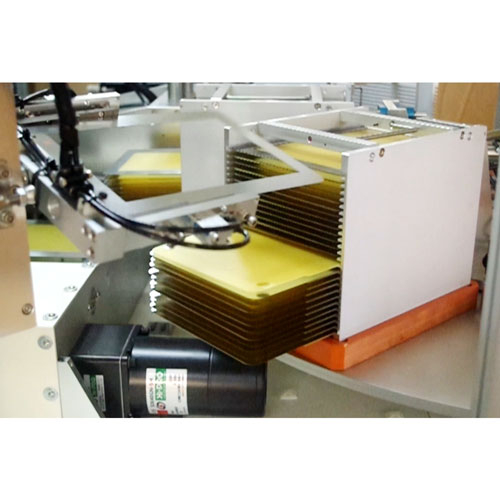

Flipping mechanism

-

Set the memory. It will turn the object over automatically when printing on the reverse side for the second time.

-

-

Gripper Arm

-

Gripper arm grasps the objects automatically.

-

-

Object breaking detection mechanism

-

Grating detects the broken NG products. It will identify and classify automatically.

-

-

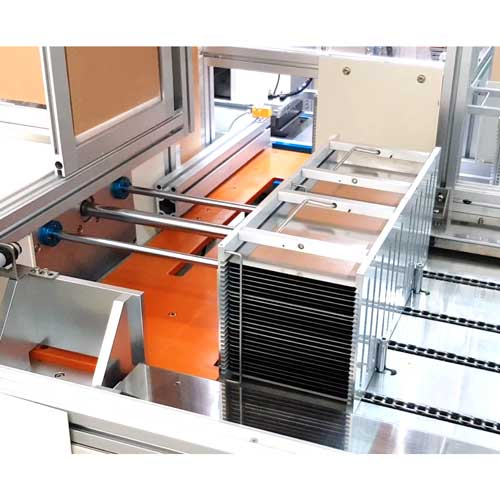

Conveying mechanism

-

The conveying mechanism conveys smoothly and quickly.

-

-

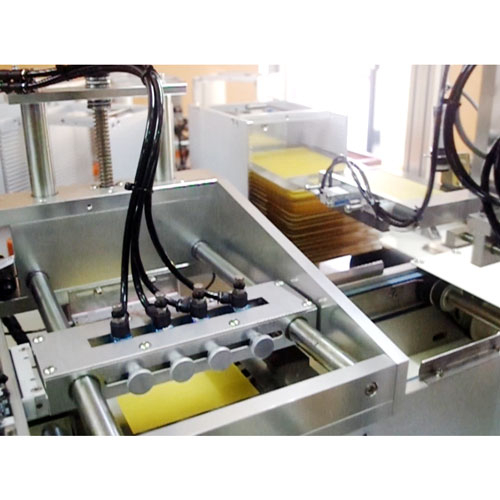

Screen printing mechanism

-

Fully automatic screen printer adopts pneumatic squeegee stand that can up and down straightly. The squeegee pressure can be adjusted individually.

-

Fully automatic screen printer adopts magnetic squeegee clip (patent number M390871).

-

Both X and Z axis adopts servo motor with linear guideway and ball screw, which is easier to adjust the the distance from printed object to screen stencil during printing.

-

-

Residual ink removing mechanism

-

Scrape off excess coating for easy maintenance of print quality.

-

-

Discharging mechanism

-

Discharging arm takes the objects out automatically.

-

-

Conveyor/oven mechanism

-

After discharging, the objects are transferred into the oven to speed up drying. Before entering the oven, the printed objects will be positioned. After baking, the objects will be cooled by fan automatically.

-

Specifications

| Model/Specification | FA-300TSN-XQ-2 |

|---|---|

| Printing Color | 1 |

| Voltage (V) | 220V 3 Phase |

| Max. Printing Area (mm) | 200*140 |

| Printed Object Height Range (mm) | 0.1~50 |

| Left and Right Stroke (mm) | 300 |

| Max. Screen Stencil Size (mm) | 400*500 |

| Platform Left and Right Tilt Angle/ Independent Squeegee Stand Lifting Distance (mm) |

10°/50 |

| Machine Size (cm) | L:570*W:180*H:210 cm |

| Conveyor Oven (cm) | Total Length 370cm (Placing Area 190cm, Baking Area 130cm, Discharging Area 50cm) |

Videos

-

Automatic Screen Printer (Printing for Magnetic Stripe Coating)-FA-300TSN-XQ-2

Automatic Screen Printer (Printing for Magnetic Stripe Coating)-FA-300TSN-XQ-2

-

FA-300TSN-XQ Automatic Two-axis Servo Screen Printer

FA-300TSN-XQ Automatic Two-axis Servo Screen Printer

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

Screen printing machines Fully Upgraded - Price remains unchanged

Screen printing machines Fully Upgraded - Price remains unchanged

-

Fine Cause Smart Screen Printing Machine - Commercial 2016

Fine Cause Smart Screen Printing Machine - Commercial 2016

Downloads

-

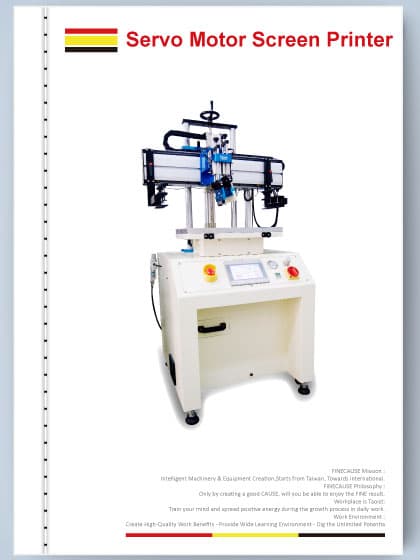

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Unitex Squeegees

Unitex Squeegees

Unitex Squeegees

-

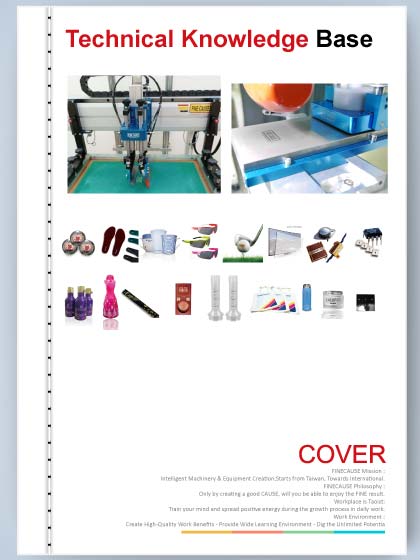

The relationship between screen printing and printing

The relationship between screen printing and printing

The relationship between screen printing and printing

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links