Products

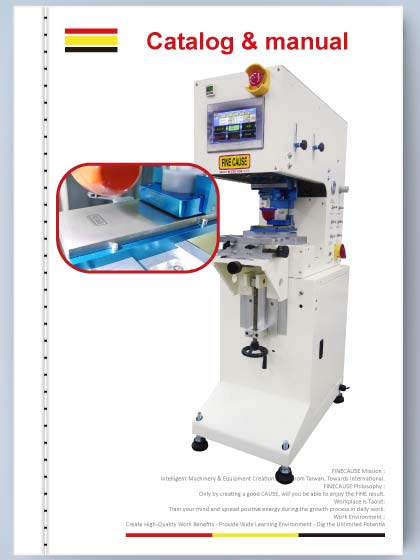

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)

Product Info

FC-192ACC-CX 2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)

-

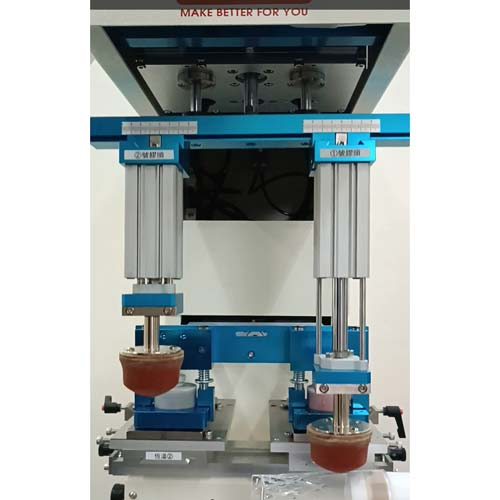

The 2-color pad printing machine is equipped with 2 sets of independent pneumatic cylinders to control. The printing pads are pressed down independently in a predetermined order.

-

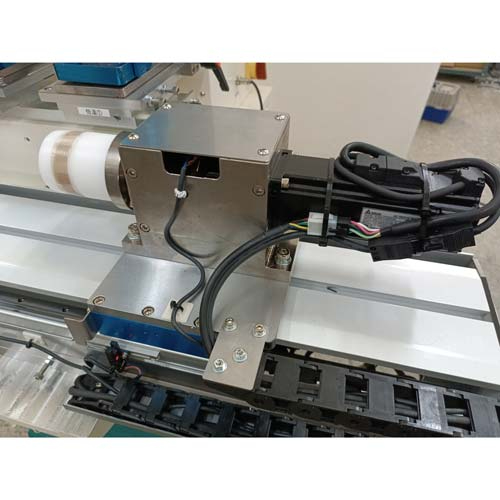

Equipped with a servo slide table and servo rotation mechanism, enabling freely fine tuning of jig angle to accommodate various printing angles and positions.

-

360 degrees rotation is available for printing; even printing on 【conical-shaped】 glass cups can achieve perfect printing.

-

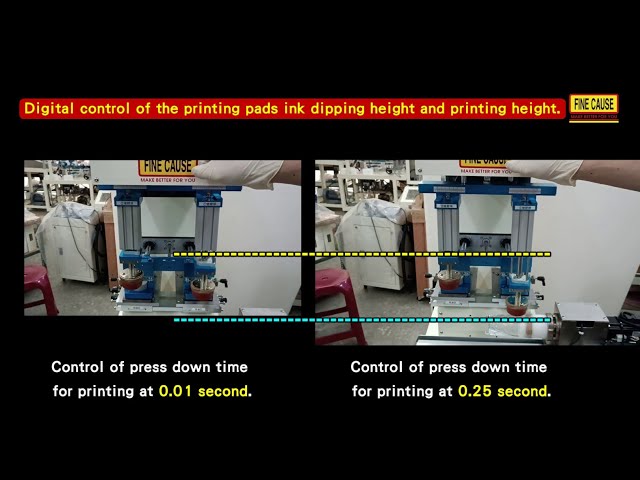

Digital control of the printing pads ink dipping height and printing height ensures accurate and easy operation.

-

The printing pad with pneumatic cylinders of two-stage downward pressure is designed to cater to custom requirements for special-shaped object.

-

The pad printing machine is equipped with a thermostatic printing system.

-

【Taiwan Invention Patent】Patent No. I762245

-

Patent pad printing technology: apply thermostatic pad printer to control the ink temperature for achieving a more ideal printing effect. The pad printing ink layer thickness is able to be increased. The ink deposit is complete and clean and the ink picks phenomenon can be improved. Raising the ink temperature during printing can accelerate the volatilization speed during ink transfer to achieve complete ink deposit and increase the ink opacity greatly.

-

-

It is possible to set and change the printing times, printing angles, and printing sequence.

-

With pressure-regulating ink scraping system (patent no. M311585), the scraping pressure of the ink cup can be adjusted easily.

-

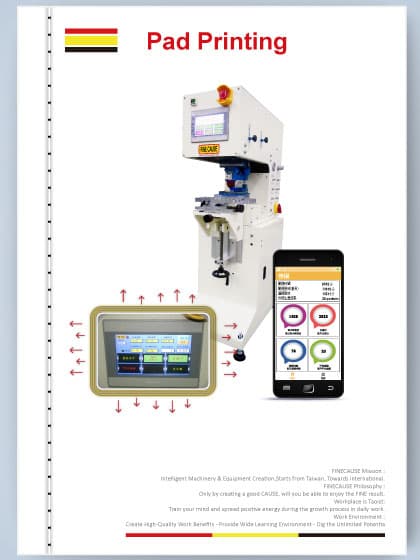

The pad printer is equipped with 7.0" 65536 color TFT touch screen.

-

Built-in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese,and Thai.

-

Adopt PLC, which is easy to add or modify functions.

-

Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With smart factory Industrial Internet of Things (I.O.T.), wherever you are, you can view the productivity report by downloading the FineCause APP.

Specifications

| Model | FC-192ACC-CX |

|---|---|

| Printing Colors | 2 |

| Suggested Max. Printing Area (mm) | Ø75 |

| Suitable Cliché Size (mm) | 120X240 |

| Productivity / Hour | 800~1500 pcs |

| Machine Size (cm) | L:90 W:78 H:156 |

| Net Weight | 140 kg |

Videos

-

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)-FC-192ACC-CX

2-Color Pad Printing Machine with Servo Slide Table and Rotation Mechanism (Add Thermostatic Printing System)-FC-192ACC-CX

-

FC-164DCC-SD Four-color Servo Pad Printer

FC-164DCC-SD Four-color Servo Pad Printer

-

FC-194DCC-CX-4 Color Ink Cup Pad Printer by Servo Sliding Table

FC-194DCC-CX-4 Color Ink Cup Pad Printer by Servo Sliding Table

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

Downloads

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

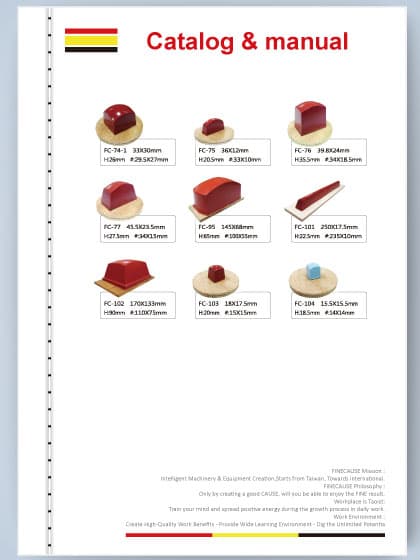

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

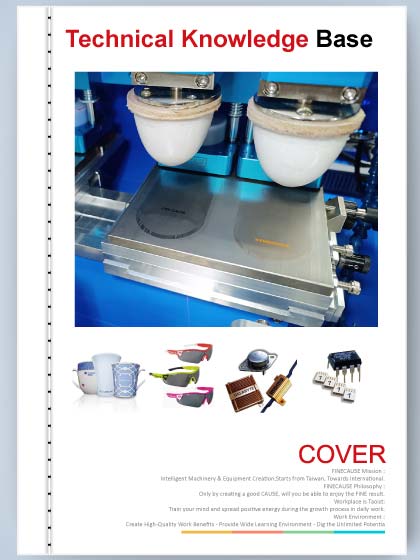

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links