Products

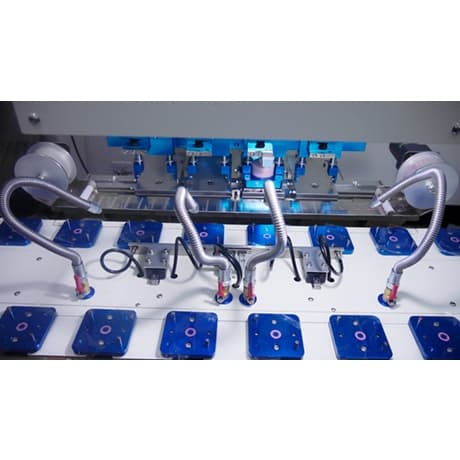

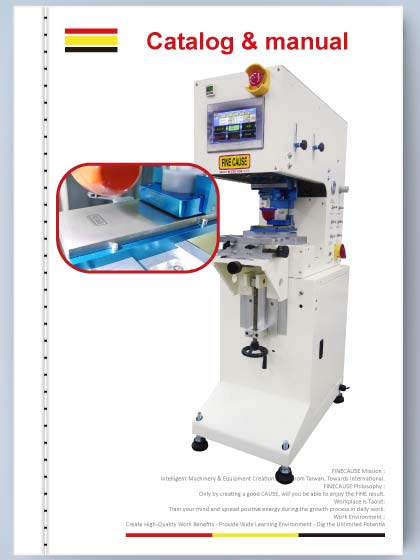

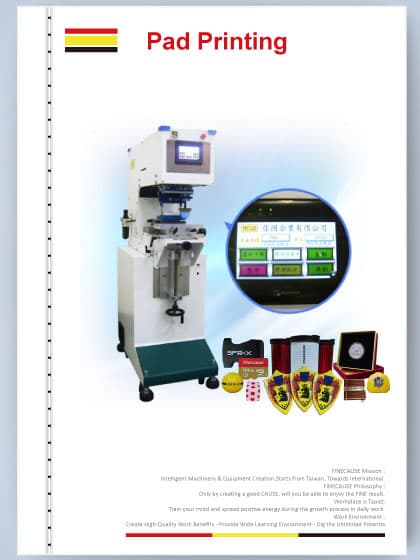

4-color pad printing machine with carousel

4-color pad printing machine with carousel

Product Info

|

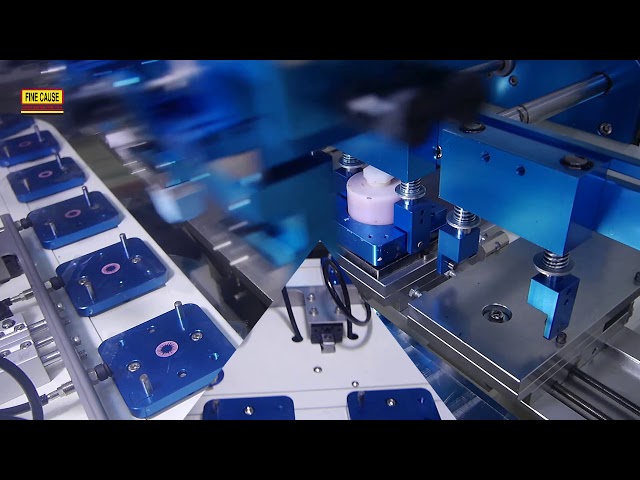

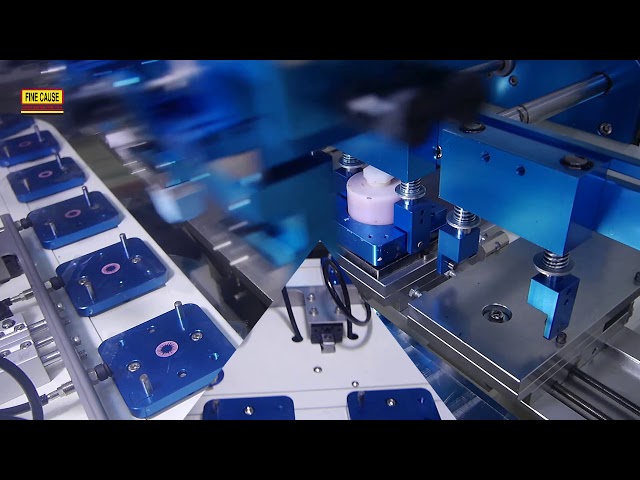

4-color pad printing machine with carousel 4 Color Ink Cup Pad Printing Machine with Servo w/Conveyor-FC-264AOC The advantage is that using four color pad printer can finish product at once. Fine Cause's pad printing machine imported to industrial I.O.T., combine smart factory App, assist you to implement production management goals through synchronous monitoring. ■ Features:

■ Suitable for:coins printing, toys, stationery, watches, accessories, electronic products, switches, buttons, lighter surface and so on. Plastic printing, metal finished products, semi-finished products, glass ceramics product or uneven surface printing. Additional precision indexing plate makes it easy to access materials. It is also able to expand the automation peripherals to increase production |

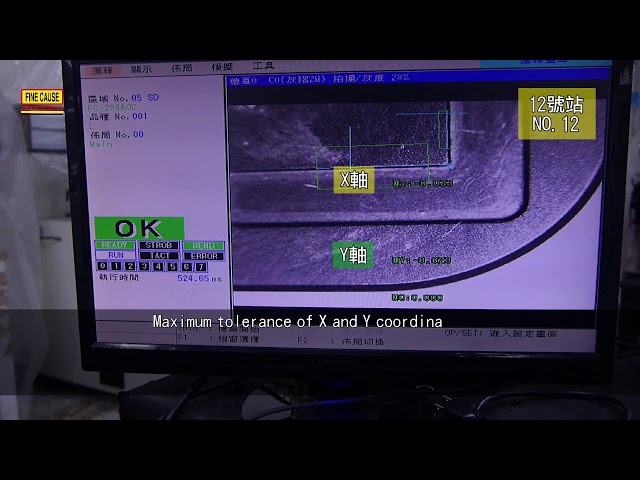

Positioning precision test

| First positioning | Second repositioning | error | ||||

|---|---|---|---|---|---|---|

| Fixture number |

X axis | Y axis | X axis | Y axis | X axis | Y axis |

| NO.1 | 0 | 0.01 | 0.001 | 0.003 | -0.001 | 0.007 |

| NO.2 | 0.039 | -0.003 | 0.038 | -0.009 | 0.001 | 0.006 |

| NO.3 | -0.001 | 0.001 | -0.001 | 0 | 0 | 0.001 |

| NO.4 | 0.021 | 0.017 | 0.031 | 0.02 | -0.01 | -0.003 |

| NO.5 | 0.022 | -0.025 | 0.024 | -0.034 | -0.002 | 0.009 |

| NO.6 | 0.026 | -0.015 | 0.027 | -0.02 | -0.001 | 0.005 |

| NO.7 | 0 | -0.007 | 0.004 | -0.013 | -0.004 | 0.006 |

| NO.8 | 0.007 | 0.02 | 0.009 | 0.025 | -0.002 | -0.005 |

| NO.9 | 0.04 | 0.016 | 0.041 | 0.011 | -0.001 | 0.005 |

| NO.10 | -0.007 | 0 | 0.006 | -0.009 | -0.013 | 0.009 |

| NO.11 | 0.039 | 0.009 | 0.039 | -0.012 | 0 | 0.021 |

| NO.12 | -0.033 | -0.023 | -0.03 | 0.026 | -0.003 | -0.049 |

| NO.13 | -0.031 | 0.003 | -0.033 | -0.002 | 0.002 | 0.005 |

| NO.14 | -0.016 | -0.003 | 0.019 | -0.006 | -0.035 | 0.003 |

| NO.15 | 0.044 | -0.027 | 0.041 | -0.028 | 0.003 | 0.001 |

| NO.16 | 0.006 | 0 | -0.008 | 0.002 | 0.014 | -0.002 |

| NO.17 | -0.033 | -0.016 | -0.037 | -0.005 | 0.004 | -0.011 |

| NO.18 | -0.007 | -0.038 | -0.017 | -0.035 | 0.01 | -0.003 |

| NO.19 | 0.051 | -0.013 | 0.047 | -0.009 | 0.004 | -0.004 |

| NO.20 | 0.031 | -0.042 | 0.031 | -0.035 | 0 | -0.007 |

| NO.21 | 0.003 | -0.028 | -0.011 | -0.024 | 0.014 | -0.004 |

| NO.22 | -0.029 | 0.017 | -0.029 | 0.018 | 0 | -0.001 |

| The maximum error of coordinate continuous operation +-0.05mm, the maximum error of repeated positioning and continuous operation +-0.01mm | ||||||

Specifications

| Machine Type | FC-264AOC |

|---|---|

| Color | 4 |

| Plate size(mm) | L:200 W:90 H:10 |

| Cycles/hr | 900~1200 Pcs |

| Machine Size (cm) | L:150 W:138 H:160 |

| Weight | 650KG |

| Pressure (kg/cm2 psi) |

4~6(kg/cm2 psi) |

| Power (A) Ampere |

10A |

| Voltage (V) | 220V |

| Max. Printing Area (mm) |

Ø50 |

| Height - Pad Stand to Steel Plate (mm) |

94 |

| Max. Steel Plate Size (mm) |

90*200 |

Videos

-

FC-264AOC Standard Servo Pad Printer

FC-264AOC Standard Servo Pad Printer

-

FC-264AOC Ink Cup Pad Printing Machine - Fully accurate positioning record

FC-264AOC Ink Cup Pad Printing Machine - Fully accurate positioning record

-

FC-264AOC Ink Cup Pad Printing Machine with Cleaning Mechanism

FC-264AOC Ink Cup Pad Printing Machine with Cleaning Mechanism

-

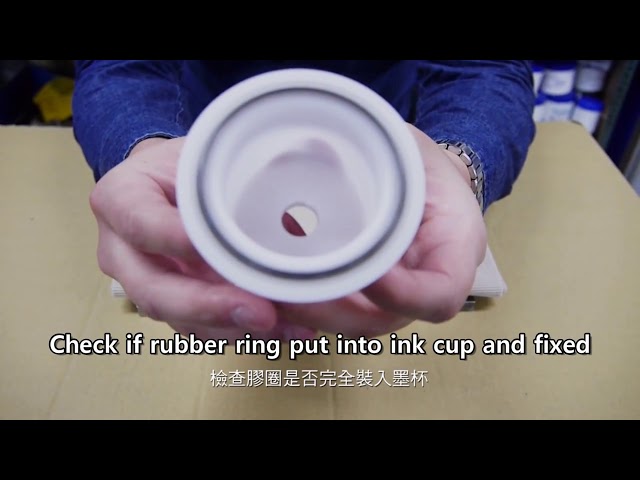

Instructions - Ink Cup Installation

Instructions - Ink Cup Installation

-

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

-

Instructions -Pad printer machine Knife Ring Tutorial

Instructions -Pad printer machine Knife Ring Tutorial

Downloads

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

Pad printing technology

Pad printing technology

Pad printing technology

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

2016 FINECAUSE pad printer features

2016 FINECAUSE pad printer features

2016 FINECAUSE pad printer features

-

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links