Products

Screen Printing Machine by Dual-Axis Servo (Shaft Bushing Type)

Screen Printing Machine by Dual-Axis Servo (Shaft Bushing Type)

Product Info

The advantages of a dual-axis servo screen printing machine:

-

High precision printing: The dual-axis servo system provides exceptional positioning accuracy and motion control capability, enabling the screen printing machine to precisely control its movements during the printing process; thus, achieving high-precision printing.

-

High-precision printing can improve production efficiency, especially for large-scale printing applications, as it helps save time and costs.

-

Stability and reliability: The dual-axis servo system possesses excellent stability and reliability, enabling it to maintain high-precision motion control during extended periods of operation. This reduces the chances of deviations or malfunctions during printing, ensuring consistent printing quality.

Why choose a dual-axis servo screen printing machine?

-

Higher printing quality: The dual-axis servo system's high precision control ensures the stability and consistency of printing quality. Fine lines can achieve superior printing results throughout the printing process.

-

Higher production efficiency: High-speed printing is a significant advantage of the dual-axis servo screen printing machine, enabling a substantial increase in production efficiency and reducing printing costs. This is especially appealing to enterprises engaged in large-scale production.

-

Stronger reliability: The dual-axis servo system's stability and reliability contribute to the printing machine's reduced likelihood of experiencing malfunctions or deviations during extended periods of operation. This decrease in downtime enhances production stability.

-

Choosing a dual-axis servo screen printing machine can enhance printing quality, production efficiency, and stability, making it a worthwhile consideration for the modern printing industry.

Screen Printing Machine by Dual-Axis Servo (Shaft Bushing Type)-FA-300TXN

-

The dual-axis servo system enables precise movement in both vertical and horizontal directions, enhancing accuracy. Adjustments can be made digitally through the HMI. The higher the left-right printing speed value, the faster the movement—up to a maximum of 999 mm per second.

-

Digital adjustments via the HMI are precise and fast, with the ability to save settings for quick switching—no need to reconfigure every time.

-

-

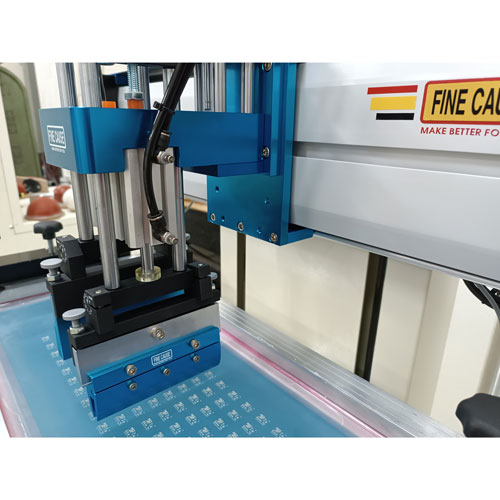

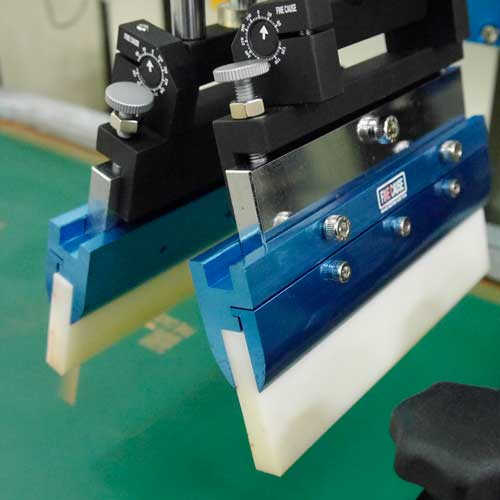

Magnetic squeegee clip (patent no. M390871)

-

The squeegee position can be easily slide, making adjustments or disassembly effortless.

-

-

The screen printing machine utilizes a pneumatic squeegee seat assembly for linear elevation.

-

The squeegee downward pressure is controlled by stepper motor, enabling fine adjustment of the downward distance. This setup is specifically designed for advanced screen printing applications.

-

Linear lifting can prevent squeegee height from deviation.

-

Linear lifting can prevent ink from flowing out of the screen stencil, which may occur on manual lifting of the squeegee.

-

Make the screen stencil cleaning more convenient and fast.

-

-

Printing and screen stencil lifting (dual-axis)

-

The screen stencil lifting adopts servo motor, allowing precise adjustment of the snap-off distance, making the production process more systematic.

-

Printing adopt servo motor and linear guideway with ball screw rod.

-

Screen stencil lifting adopt servo motor with shaft bushing.

-

The servo linear lifting can be set to reduce the speed of lowering or raising the screen stencil at specific positions.

-

-

The screen printing machine adopts 7" HMI (65536 color TFT touch interface) and built in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

Abnormal alarm display is convenient for operator to quickly eliminate abnormalities.

-

Electronic air pressure sensing will alarm automatically for insufficient air pressure.

-

The screen stencil usage times can be set. When the set value reaches, the machine will automatically stop and alarm.

-

-

Production history function: Built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With WIFI function, if to connect with FineCause smart factory APP, no matter where you are, you can view the machine productivity report anytime and anywhere.

-

Specifications

| Model | FA-300TXN |

|---|---|

| Printing Color | 1 |

| Productivity / Hour | 600~1800 |

| Machine Size (cm) | L:77 W:58 H:168 |

| Air Pressure (kg/cm2 psi) | 4~6 |

| Power Consumption (a) | 5A |

| Voltage (v) | 220V Single Phase |

| Platform Size (mm) | 100*220 |

| Max. Printing Area (mm) | 140*200 |

| Allowable Object Height (mm) | 200 |

| Left and Right Stroke (mm) | 300 |

| Max. Screen Stencil Lifting Stroke (mm) | 360 |

| Platform Left and Right Fine Tune Distance (mm) |

±8 |

| Platform Left and Right Tilt Angle/ Lifting Distance of Independent Squeegee Set (mm) |

10°/50 |

| Net Weight | 165KG |

Videos

-

FA-500TXN-Dual Axle Servo Motor Platform Screen Printer

FA-500TXN-Dual Axle Servo Motor Platform Screen Printer

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

Screen printing machines Fully Upgraded - Price remains unchanged

Screen printing machines Fully Upgraded - Price remains unchanged

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Clean Screen Printing Plate Tutorial

Clean Screen Printing Plate Tutorial

-

How to recognize Nylon screen and Tetoron screen?

How to recognize Nylon screen and Tetoron screen?

Downloads

-

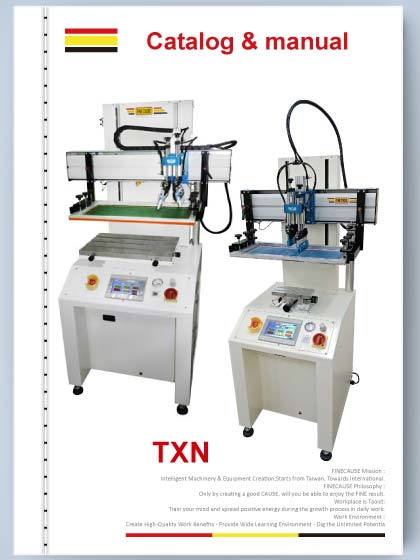

Screen Printing Machine by Dual-Axis Servo-FA-300/500TXN

Screen Printing Machine by Dual-Axis Servo-FA-300/500TXN

Screen Printing Machine by Dual-Axis Servo-FA-300/500TXN

-

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

-

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

-

The relationship between screen printing and printing

The relationship between screen printing and printing

The relationship between screen printing and printing

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links