Reference

Wet Grinding Materials: The Key to Efficient Lapping and Polishing

| Filename | Wet Grinding Materials-The Key to Efficient Lapping and Polishing.pdf |

| File Size | 747.9KB |

| Revision Date | 2025/07/30 |

Wet Grinding Materials: The Key to Efficient Lapping and Polishing

In modern industrial processes, wet grinding materials play an indispensable role. With the assistance of liquid media, wet grinding effectively reduces friction and heat, thereby enhancing grinding efficiency and product quality. They are widely used in fields such as metal processing, ceramics, electronic components, coatings, chemicals, and semiconductor wafers.

What Are Wet Grinding Materials?

Wet grinding refers to grinding and polishing operations carried out in water or other liquid media. Its purpose is to reduce heat and dust generated during processing while improving flatness and uniformity. Compared with dry grinding, wet grinding offers better cooling performance and eco‑friendliness, making it the ideal choice for nano‑scale processing and high‑quality surface finishing.

Common Types of Wet Grinding Materials

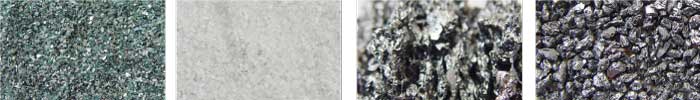

The market offers a wide variety of abrasives, each with unique features. Common examples include:

-

Green Silicon Carbide (GC)

-

White Aluminum Oxide, Pink Aluminum Oxide.

-

Garnet, Glass Beads

-

Zirconia Alumina (Coarse Grinding Abrasive)

-

Brown Aluminum Oxide, Black Silicon Carbide

-

Steel Shot, Steel Grit

When selecting the right material, factors such as the hardness of the workpiece, required surface roughness, and compatibility with the grinding equipment must be carefully considered.

Recommended Application: Green Silicon Carbide (GC)

Green Silicon Carbide is produced from quartz sand and petroleum coke in a high‑temperature electric furnace. It features purity above 99.5%, high hardness, and excellent chemical stability.

Key Features:

-

Hardness second only to diamond

-

Self‑fracturing sharp edges for improved grinding efficiency

-

Outstanding performance on high‑precision wafers, oscillators, aluminum, and copper materials

-

Excellent thermal conductivity and high‑temperature resistance, ideal for ceramic processes

Applications:

-

SKD11 steel plate re‑lapping for pad printing (matte finish, scratch‑resistant, longer lifespan)

-

Ceramics, smartphone panels, wafers, aluminum parts, and hard materials

👉 Product Page: FUJIMI Green Silicon Carbide

Imported from FUJIMI INCORPORATED, Japan, this high‑purity green silicon carbide is specifically designed for wet grinding. Featuring excellent hardness and wear resistance, it is widely applied to steel plates, ceramics, wafers, and precision parts. With strict particle size control and a clean production process, it delivers finer and more predictable polishing results, making it the top choice for industries demanding premium surface quality.

⚙️ Recommended Machine Match: FC‑Steel‑3 Wet Lapping & Polishing Machine

For optimal performance, pair with the FC-Steel-3Automatic Lapping and polishing machine, engineered for steel plates, wafers, and precision components.

-

Automatic reciprocating platform for uniform grinding without jamming (Patent No. M672344)

-

Processes up to 4 pieces simultaneously — efficient and time‑saving

-

Wet liquid circulation design prevents overheating and dust generation

-

User‑friendly multilingual interface (Chinese / English / Vietnamese / Indonesian / Thai)

📌 Learn More: FC‑Steel‑3 Medium‑Size Automatic Wet Grinding & Polishing Machine

Zirconia Alumina (Coarse Grinding Abrasive): A Popular Long‑Term Choice

Zirconia Alumina is a synthetic high‑hardness abrasive known for excellent hydrophilicity and electrostatic properties, widely used in grinding, polishing, and sandblasting.

Features:

-

Self‑sharpening effect for strong cutting power

-

High durability and consistent grit size

-

Smooth and uniform surface finishing

Applications:

-

Zinc plates, molds, IC deburring

-

Sandblasting for rust/paint removal, glass engraving

⚙️ Machine Match: FC‑Steel‑2 Wet Grinding/Polishing Machine (Small Size)

Compact design with a 720mm worktable, dedicated for high‑efficiency grinding of steel plates and precision components.

-

Four pneumatic rings for 1/2/4 workpieces, synchronous or independent operation

-

Multiple working modes: synchronous, alternate, or independent control

-

Adjustable dwell time and reciprocation cycles

-

Independent AC motors with variable speed for precise control

Suitable for grinding metals and non‑metals such as SKD11 heat‑treated steel plates, ceramic parts, sapphire, phone components, watch glass, tungsten carbide, and silicon.

📌 See More Wet Grinding Machines Here...

Proven Results from Fine Cause

Through extensive testing, Fine Cause found that FUJIMI Green Silicon Carbide and Zirconia Alumina each deliver excellent results on pad printing steel plates and SKD11 plates.

-

Green Silicon Carbide produces a matte finish, enhances scratch resistance, extends steel plate life, and ensures smoother surfaces with fewer abrasive marks — leading to higher precision printing results.

-

Compared to White Aluminum Oxide, FUJIMI Green Silicon Carbide showed superior surface smoothness and reduced friction between steel plates and doctor rings, extending the lifespan of ink cups and rings.

Fine Cause also offers pad printing steel plate re‑lapping services. By re‑lapping with FUJIMI Green Silicon Carbide, plates become more durable and reusable for new designs, effectively lowering printing costs while extending plate life.

✅ Conclusion: Unlock Higher Efficiency with the Right Wet Grinding Materials

The combination of wet grinding materials and wet lapping machines is key to improving process stability, surface quality, and production efficiency. Whether for precision steel plates, electronic materials, or hard ceramics, choosing the right abrasive reduces costs, extends tool and workpiece lifespan, and enhances yield rates — making it a critical element in modern manufacturing.

👉 Further Reading: How to Choose the Right Wet Grinding & Polishing Machine?

Click the product names above to view full descriptions—or contact us to learn more!

...For the complete color image file, please click the Download button.

Links

Links