Products

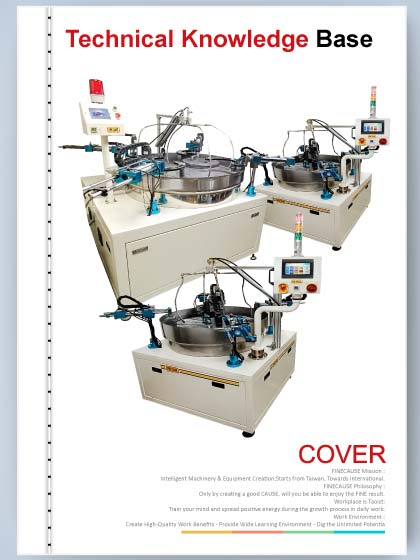

Lapping Polishing Machine(Small-Scale )

Lapping Polishing Machine(Small-Scale )

Product Info

Lapping Polishing Machine(Small-Scale )-FC-Steel-2

Compact in size, high in efficiency—an ideal choice for steel plate regeneration!

Developed in-house by FINE CAUSE, the FC-Steel-2 combines semiconductor-grade polishing techniques with practical engineering, making steel plate regrinding fast and cost-effective.

Suitable for a wide range of materials, including:

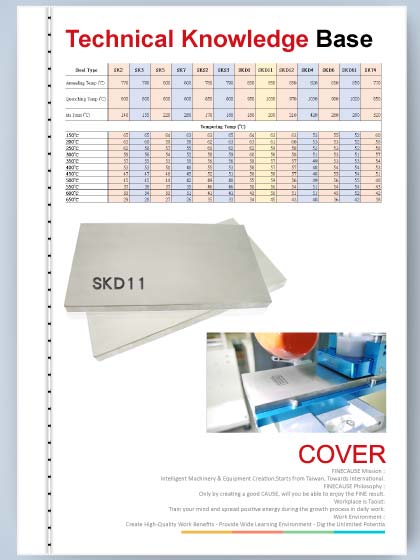

SKD11 heat-treated plates, ceramic components, sapphire, mobile device parts, watch glass, tungsten carbide, silicon, and more.

Key Design Features:

Wet lapping system design

Closed-loop slurry flow helps maintain stable platen temperature and avoids deformation caused by overheating.

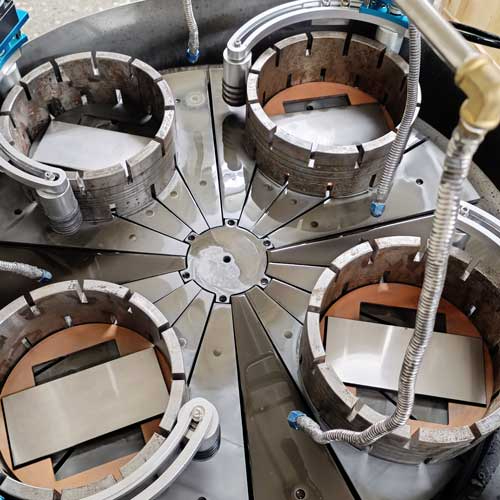

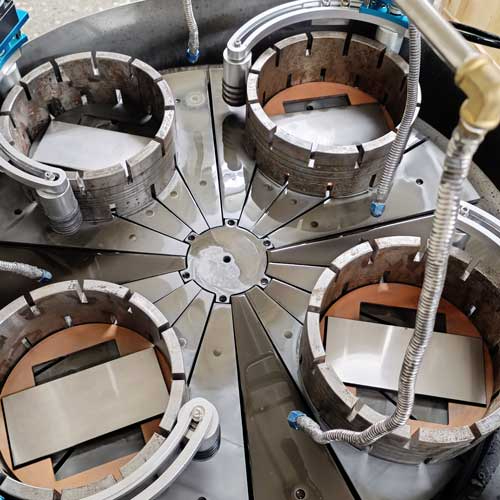

720mm Platen Diameter

Can accommodate up to four 90×200mm or two 120×240mm plates (depending on work ring configuration).

Four Pneumatically-Driven Work Rings

Allow for flexible single, dual, or quad-piece operation—either in sync or independently.

Adjustable Motion & Intelligent Controls

-

Multiple motion modes: synchronized, sequential, and individual control

-

Customizable delay time and reciprocation count

-

Independent stroke settings for each work ring

-

Each part rotates via an individual small AC motor (single-phase 220V), with stepless speed adjustment

User-Friendly HMI Panel

-

7” touch screen (Weintek MT8071iE) supporting Traditional Chinese, English, Vietnamese, Indonesian, and Thai

-

Real-time display of machine status and parameter settings

-

Manual component testing, sensor monitoring, and timeout alarm features

Patented Design Advantages

-

Pneumatic push-ring system reduces manual error and mechanical wear

-

Detachable abrasive modules for easy maintenance and quick replacement

-

Multi-point displacement structure avoids localized platen wear

-

Optional polishing pads and diamond lapping film available for multi-stage processing

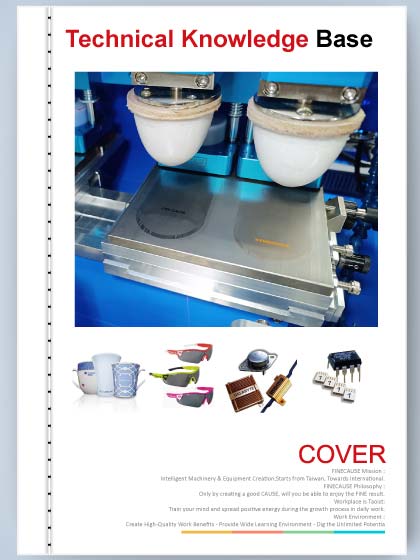

Applicable Materials & Workpieces

-

Metals: Cast iron, copper, aluminum, alloy steel, high-carbon steel, platinum, gold, silver, etc.

-

Non-metals: Glass, silicon, quartz, rubber, plastic, marble, ceramic, and more

Application Examples:

-

SKD11 plate regrinding (extending tool life)

-

Precision valve plates, water-stopper valves, wafer components

-

Compressor and refrigeration components

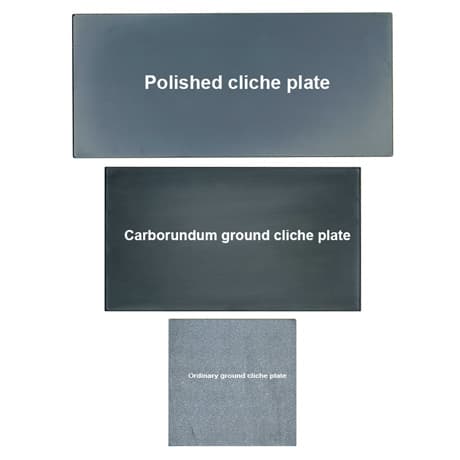

🔄 Typical 3-Stage Lapping Process (e.g., for pad printing plates)

-

1️⃣ Rough Grinding: Surface imperfections removed using a wheel-based surface grinder

-

2️⃣ Fine Grinding: Wet lapping using diamond slurry for surface refinement

-

3️⃣ Mirror Polishing: Achieve ultra-flat, glossy finish with polishing pad and compound

⚠️ Most industries stop at stage two, but high-spec industries such as contact lens mold making and semiconductors require final-stage mirror polishing.

Fine Cause uses the FC-Steel-3 automatic lapping and polishing machine / wet grinding equipment together with FUJIMI Green Silicon Carbide for surface grinding, allowing pad printing steel plates to be reused with new patterns, effectively extending plate life and reducing costs.

👉 [Related Article] How to Choose the Right Wet Lapping & Polishing Machine

👉 [Related Article] What Are Wet Grinding Materials? Learn the Key to High-Efficiency Polishing

🔬 Backed by R&D Expertise × 23 Years of Experience

Supported by Taiwan’s Ministry of Economic Affairs (CITD program)

Over 23 years of wet lapping and polishing experience

We offer test runs, process development, parameter setup, and custom machine design

FINE CAUSE – Your trusted partner in automated wet lapping & polishing solutions.

Videos

-

FC Thin Cliche Plate

FC Thin Cliche Plate

-

Laser Engraving Cliche Plate (thick)

Laser Engraving Cliche Plate (thick)

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Fine Cause Smart Screen Printing Machine - Commercial 2016

Fine Cause Smart Screen Printing Machine - Commercial 2016

-

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

Downloads

-

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

-

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

-

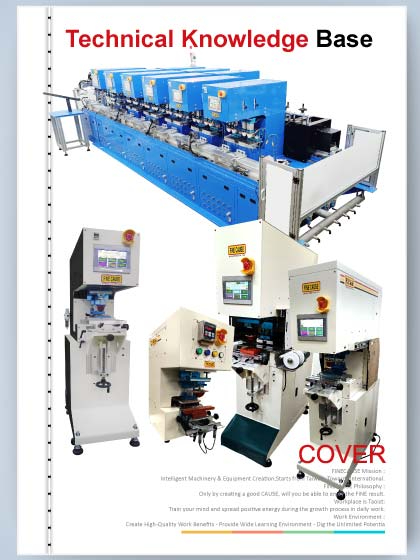

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links