Products

Green Silicon Carbide – FUJIMI-GC

Green Silicon Carbide – FUJIMI-GC

Product Info

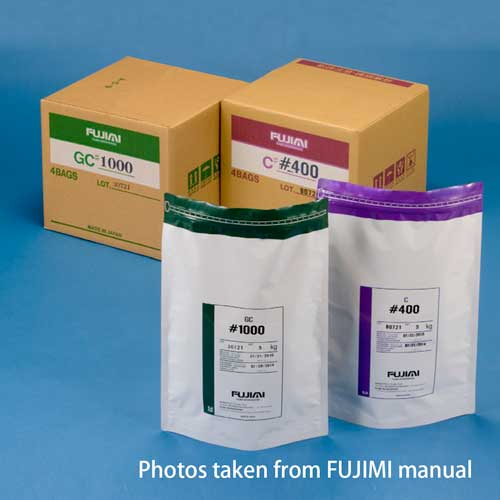

Green Silicon Carbide | Imported from FUJIMI INCORPORATED, Japan

This high-purity Green Silicon Carbide from FUJIMI INCORPORATED, Japan, is specially designed for wet grinding machines and represents a premium choice among wet grinding materials. Featuring an α-type hexagonal crystal structure with a purity of up to 99.5%, its hardness ranks just below diamond. With excellent chemical stability and high-temperature resistance, its self-sharpening edges significantly improve polishing efficiency and surface fineness, making it a trusted choice in high-precision processing industries.

High-Purity, High-Hardness Material Tailored for Wet Grinding Machines

Green Silicon Carbide is formed by fusing silica and petroleum coke under high-temperature electric resistance, producing vivid green α-type hexagonal crystals with a purity of up to 99.5%. With hardness second only to diamond, it offers excellent chemical stability and heat resistance. As a wet grinding material, it naturally fractures into sharp edges during the process, enhancing polishing efficiency and precision.

Why Choose FUJIMI Green Silicon Carbide for Wet Grinding?

High-Performance Crystal Structure: Produced from silica and coke, featuring an α-type lattice structure with high hardness and chemical stability.

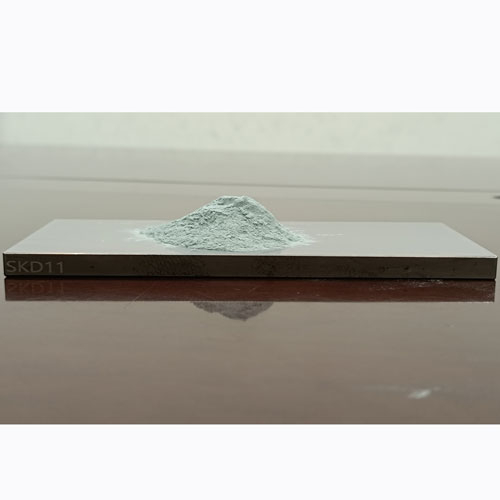

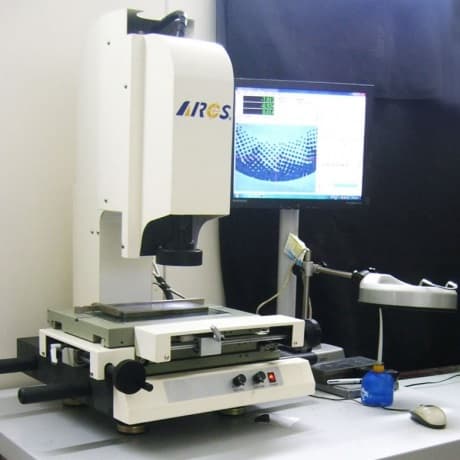

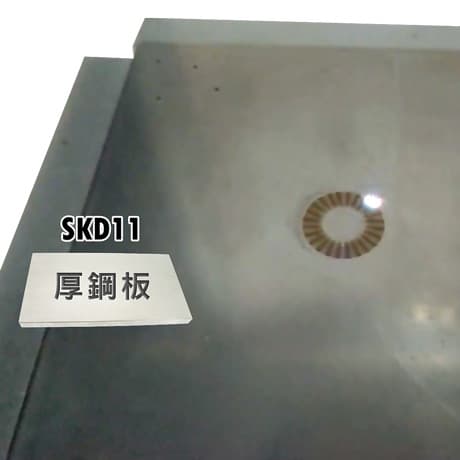

Wide Application Range: Ideal for wet grinding and advanced surface finishing of crystals, wafers, oscillators, copper, brass, and SKD11 steel plates.

Excellent Functionality & Stability: Offers superior heat resistance and thermal conductivity, making it an ideal ceramic material for wet polishing.

Outstanding Results on SKD11 Steel Plates: Produces smoother surfaces, fewer scratches, and finer patterns.

Product Features

-

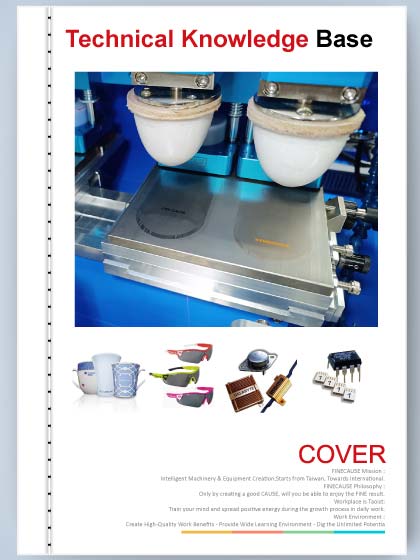

Suitable for Precision Cutting and Grinding: Crystals, wafers, oscillators, ingots, etc.

-

Compatible with Hard and Soft Metals: Such as SKD11, brass, and copper alloys.

-

Usable with Resin Products or Degassing Applications

-

Excellent Semiconductor Properties: Fast thermal conductivity, high-temperature resistance, and ideal for advanced ceramic materials.

-

Superior on SKD11 Steel Plates: Produces smoother surfaces, fewer scratches, and finer detail in patterns.

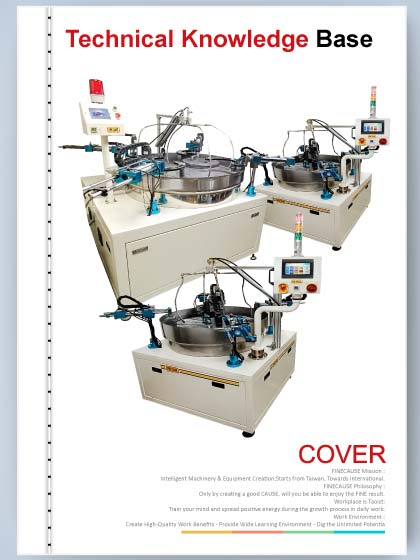

Recommended Combination: FUJIMI Wet Grinding Material × FC-Steel-3 Lapping Polishing Machine

Pairing FUJIMI Green Silicon Carbide with the FC-Steel-3Automatic Lapping and polishing machine maximizes grinding performance.

Designed for precision grinding, FC-Steel-3 features:

-

Automatic reciprocating platform for uniform grinding without clogging (Utility Model Patent M672344)

-

Supports up to 4 workpieces simultaneously, significantly improving efficiency

-

Wet liquid circulation system for effective cooling and dust suppression

-

Multi-language HMI: Chinese / English / Vietnamese / Indonesian / Thai

-

Suitable for wet grinding applications such as steel plates, wafers, and precision components.

When paired with this polishing machine, FUJIMI Green Silicon Carbide fully leverages its high hardness and self-fracturing characteristics, achieving optimal grinding efficiency and superior surface precision.

Click here to explore more wet lapping and polishing machines…

👉 [Related Article] How to Choose the Right Wet Lapping & Polishing Machine

👉 [Related Article] What Are Wet Grinding Materials? Learn the Key to High-Efficiency Polishing

Specifications

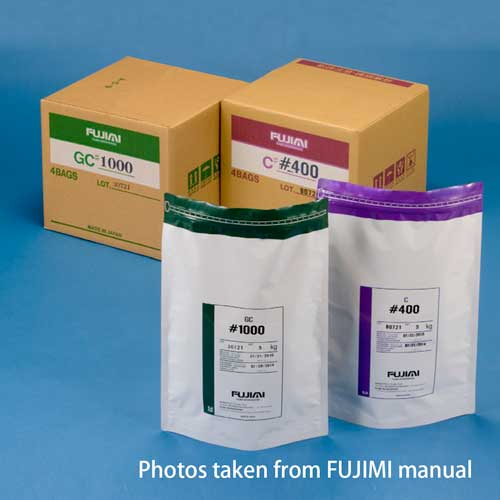

| Packaging: 20 kg / carton (inner packaging: 4 packs × 5 kg, sealed in original moisture-proof zip bags) |

|||||

|---|---|---|---|---|---|

| Particle Size |

Maximum particle size |

Particle size at 3% point (μm) |

Particle size at 50% point (μm) |

Particle size at 94% point (μm) |

Vinyl lined Net weight (kg) |

| #240 | ≤127 | ≤103 | 58.6 ± 3.0 | ≥40.0 | 20 |

| #280 | ≤112 | ≤87.0 | 49.4 ± 3.0 | ≥33.0 | 20 |

| #320 | ≤98.0 | ≤74.0 | 41.1 ± 2.5 | ≥27.0 | 20 |

| #360 | ≤86.0 | ≤66.0 | 36.1 ± 2.0 | ≥23.0 | 20 |

| #400 | ≤75.0 | ≤58.0 | 30.9 ± 2.0 | ≥20.0 | 20 |

| #500 | ≤63.0 | ≤50.0 | 26.4 ± 2.0 | ≥16.0 | 20 |

| #600 | ≤53.0 | ≤43.0 | 21.1 ± 1.5 | ≥13.0 | 20 |

| #700 | ≤45.0 | ≤37.0 | 17.9 ± 1.3 | ≥11.0 | 20 |

| #800 | ≤38.0 | ≤31.0 | 14.7 ± 1.0 | ≥9.0 | 20 |

| #1000 | ≤32.0 | ≤27.0 | 11.9 ± 1.0 | ≥7.0 | 20 |

| #1200 | ≤27.0 | ≤23.0 | 9.90 ± 0.80 | ≥5.5 | 20 |

| #1500 | ≤23.0 | ≤20.0 | 8.40 ± 0.60 | ≥4.5 | 20 |

| #2000 | ≤19.0 | ≤17.0 | 6.90 ± 0.60 | ≥4.0 | 20 |

| #2500 | ≤16.0 | ≤14.0 | 5.60 ± 0.50 | ≥3.0 | 20 |

| #3000 | ≤13.0 | ≤11.0 | 4.00 ± 0.50 | ≥2.0 | 20 |

| #4000 | ≤11.0 | ≤8.0 | 3.00 ± 0.40 | ≥1.3 | 20 |

| #6000 | ≤8.0 | ≤5.0 | 2.00 ± 0.40 | ≥0.8 | 20 |

| #8000 | ≤6.0 | ≤3.5 | 1.20 ± 0.30 | ≥0.6 (※1) | 20 |

| #10000 | — | — | 0.51 ~ 0.70 | — | 10 |

| #20000 | — | — | 0.50 ※(2) | — | |

| #30000 | — | — | 0.32 ※(2) | — | |

| The above specifications are based on the original manufacturer's catalog. Any changes are subject to the manufacturer's latest version. |

|||||

Videos

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

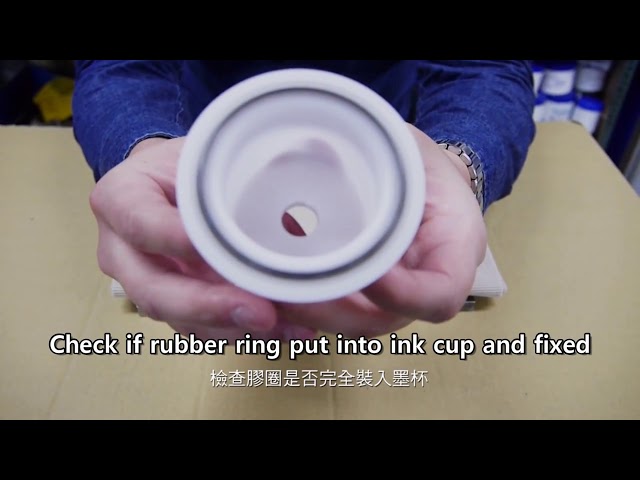

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

-

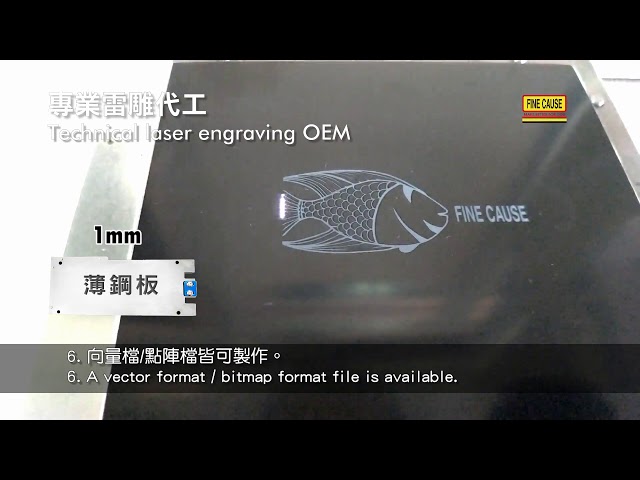

FC Thin Cliche Plate

FC Thin Cliche Plate

-

Automatic Lapping and Polishing Machine (Medium Type)-FC-Steel-3

Automatic Lapping and Polishing Machine (Medium Type)-FC-Steel-3

-

Instructions -Pad printer machine Knife Ring Tutorial

Instructions -Pad printer machine Knife Ring Tutorial

-

Steel Plate Grinder

Steel Plate Grinder

Downloads

-

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

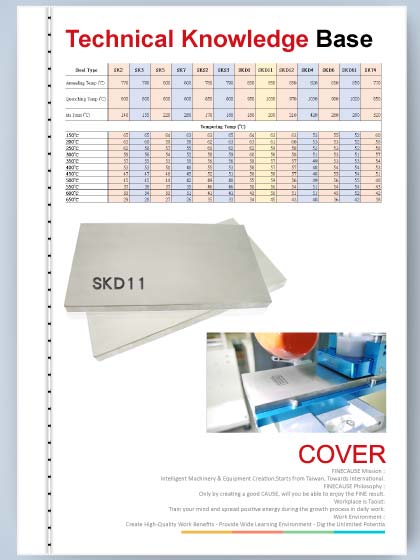

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

-

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links