Products

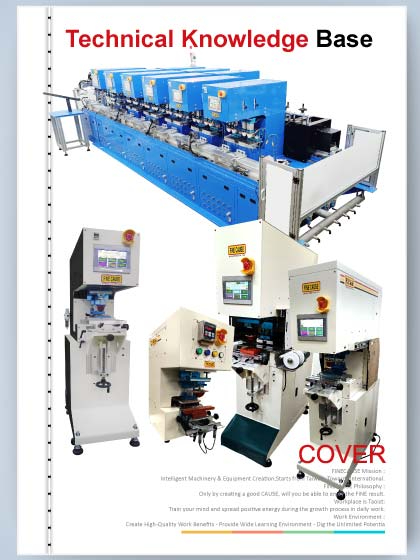

Automatic Lapping Polishing Mmachine/Lapping Equipment (medium size)

Automatic Lapping Polishing Mmachine/Lapping Equipment (medium size)

Product Info

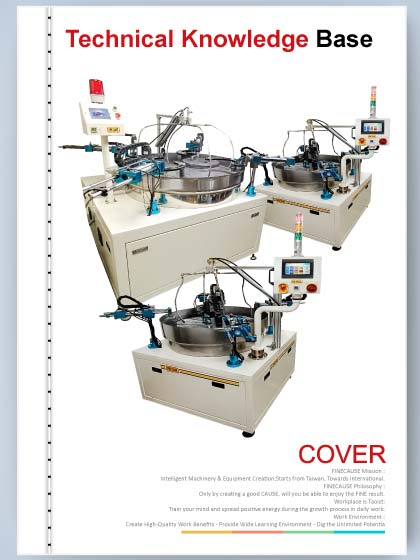

FC-Steel-3 Automatic Lapping Polishing Machine (Medium Type Wet Lapping Equipment)

Multi-Workpiece Precision Processing × Adjustable Work Rings × High-Efficiency Mirror Polishing

FC-Steel-3 is designed specifically for medium-sized workpieces and supports wet precision lapping and polishing of various metal and non-metal materials. It is ideal for applications such as SKD11 steel plates, ceramic components, wafer and chip materials, and aluminum parts, ensuring excellent flatness and surface roughness control.

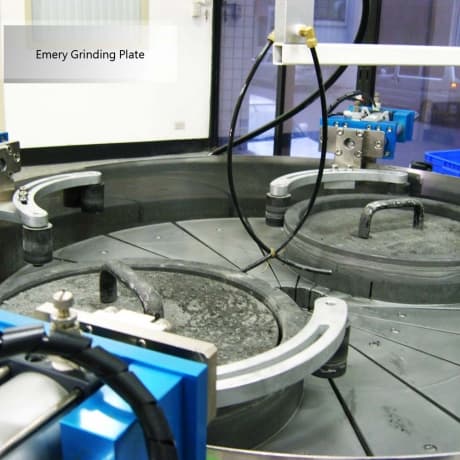

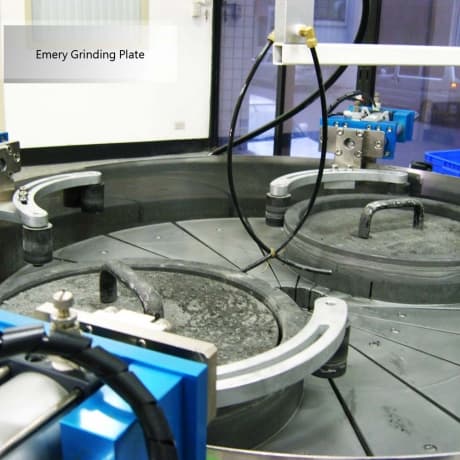

Wet lapping system design

-

Circulating slurry system: The slurry is automatically circulated to maintain stable lapping plate temperature, effectively preventing workpiece deformation caused by excessive heat.

-

800 mm worktable diameter: Supports maximum workpiece size up to 480 × 280 mm (depending on the selected work ring configuration).

- Four adjustable work rings: Flexible setup for single-piece, dual-piece, or four-piece simultaneous processing.

Multi-motion modes and control features

-

Adjustable processing parameters

-

Three work ring movement modes: synchronous, alternating, and independent operation

-

Customizable dwell time and reciprocation cycles

-

Worktable rotation speed adjustable as needed

Adjustable work rings

Configuration: Four work rings in total, each driven by a cylinder to achieve reciprocating motion.

Motion modes:

-

Synchronous mode: Work rings 1 and 3 operate simultaneously; upon completion, work rings 2 and 4 perform the motion.

-

Sequential mode: Work rings perform reciprocating motion in sequence (1 → 2 → 3 → 4).

-

Independent mode: Any single work ring can be operated independently as required.

Motion parameters:

The reciprocation cycles for each work ring can be independently configured, and the dwell times for forward and backward can be individually adjusted.

Rotary motor:

-

Rotary motor power: AC single-phase 220V, 6W x 4 units;

-

When the workpiece is positioned within the work ring, the small motor drives the rotation of the workpiece, with individually adjustable stepless speed control.

Intelligent operation interface

-

Equipped with a 7" Weintek MT8071iE HMI.

-

Multilingual interface: Traditional Chinese, English, Vietnamese, Indonesian, Thai.

-

The interface displays real-time operating status and all key settings.

-

Supports manual testing of individual components, sensor status display, and overtime alarm functions.

FineCause patented design advantages

-

Pneumatic cylinder-driven design: Automatically drives the work rings, reducing manual operation wear.

-

Detachable lapping pad module: Enables easy daily maintenance and quick replacement.

-

Multi-segment lapping block structure: Ensures uniform slurry distribution and enhances overall processing consistency.

-

Four-point displacement structure: Prevents excessive wear in localized areas of the lapping plate and extends equipment lifespan.

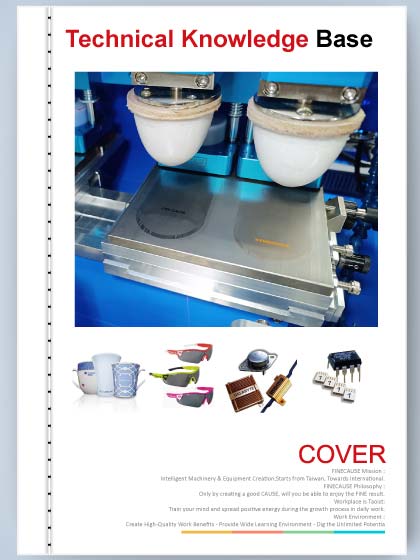

Precision lapping results showcase

-

The surface roughness measurement report can be provided.

-

Different grades of diamond abrasive and dedicated polishing pads can be selected according to your requirements to achieve multi-stage polishing levels.

-

Test lapping for various workpieces is available — contact us to schedule an appointment!

-

Applicable materials and applications

Materials that can be lapped:

Cast iron, aluminum, copper, platinum, gold, silver, high-carbon steel, alloy steel, glass, ceramics, rubber, plastics, quartz, silicon, granite, marble, nylon, carbon, and more.

Common workpieces:

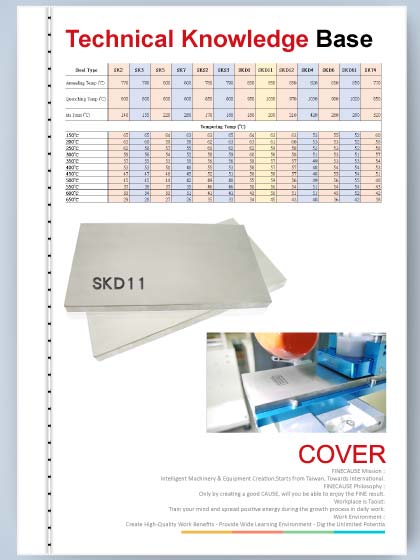

SKD11 pad printing steel plates (heat-treated), ceramic components, tungsten carbide parts, crystal materials, watch glass, sapphire, water valves, mobile phone components, oscillators, clutch plates, refrigeration compressor parts, and others.

Typical lapping process (Example: SKD11 steel plate)

-

1️⃣ Rough grinding: Surface irregularities are removed using a surface grinding machine with a grinding wheel.

-

2️⃣ Precision lapping: The surface is refined using a wet lapping machine with diamond abrasive slurry.

-

3️⃣ Mirror finishing: A polishing compound and polishing pad are used to achieve high gloss and excellent flatness.

⚠️ Most processing ends at the second stage. However, industries with higher standards—such as contact lens and semiconductor manufacturing—require the third stage of mirror polishing.

Fine Cause uses the FC-Steel-3 automatic lapping and polishing machine / wet grinding equipment together with FUJIMI Green Silicon Carbide for surface grinding, allowing pad printing steel plates to be reused with new patterns, effectively extending plate life and reducing costs.

👉 [Related Article] How to Choose the Right Wet Lapping & Polishing Machine

👉 [Related Article] What Are Wet Grinding Materials? Learn the Key to High-Efficiency Polishing

More information

Applicable for wet lapping machines, automatic lapping and polishing machines, and other lapping and polishing equipment. Compatible with diamond abrasive and optional self-adhesive polishing pads for different levels of surface finishing.

Specifications

| Model | FC-Steel-3 |

|---|---|

| Power Supply | 3-Phase 220V |

| Work Ring Quantity | 4 sets |

| Maximum Lapping Size | Single Piece 480x280 mm |

| Machine Dimensions | L:145 W:144 H:188 cm |

| Net Weight | 1170 kg |

Videos

-

Automatic Lapping and Polishing Machine (Medium Type)-FC-Steel-3

Automatic Lapping and Polishing Machine (Medium Type)-FC-Steel-3

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Magnetic Toolbox-(Magnetic Containers)

Magnetic Toolbox-(Magnetic Containers)

Downloads

-

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

-

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

-

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links