Products

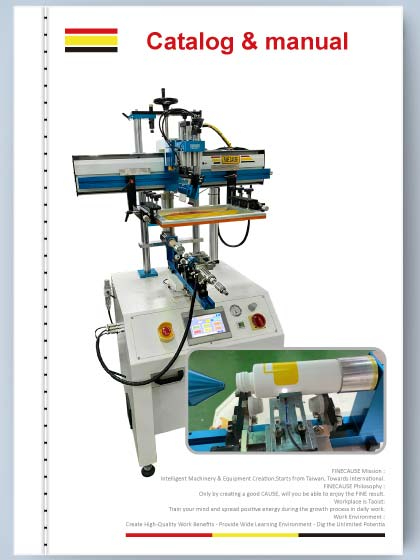

Curved Surface Screen Printing Machine(Color Senso+Servo Rotary+Custom Fixtures)

Curved Surface Screen Printing Machine(Color Senso+Servo Rotary+Custom Fixtures)

Product Info

FA-400RSM-CY Curved Surface Screen Printing Machine

(Color Sensor Registration + Servo Rotary Drive + Custom Fixtures)

Key Features

🌀 Dual-Mode Curved Surface Screen Printing Design

-

Custom Fixtures: Tailor-made fixtures can be created for uniquely shaped products. All settings can be saved directly into the HMI for fast reuse

-

Interchangeable Servo Rotary Module: Supports 360° rotary printing for cylindrical products. Rotation angle and speed are digitally controlled via servo motor.

-

Two-in-One Machine: Easily switches between curved surface and cylindrical printing modes for production flexibility.

Color Sensor Registration System

-

Integrated color sensor detects previously printed color layers to digitally define the print start point

-

Delivers stable and precise multi-color registration, even for second or third layers.

-

Whether printing one or multiple colors, the system ensures consistent and accurate alignment every time.

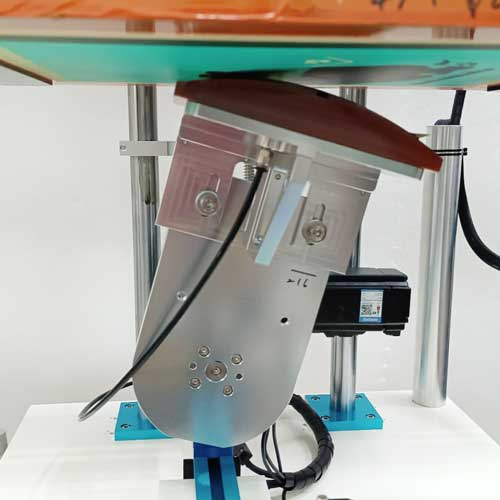

Servo Rotary Motor Module

-

Replaces traditional gear and rack mechanisms with a fully digitally controlled servo system.

-

Enables smooth, jitter-free motion, improving print stability and quality.

-

Integrated with a lightweight, low-noise, and fast-responding extrusion-molded servo slide base.

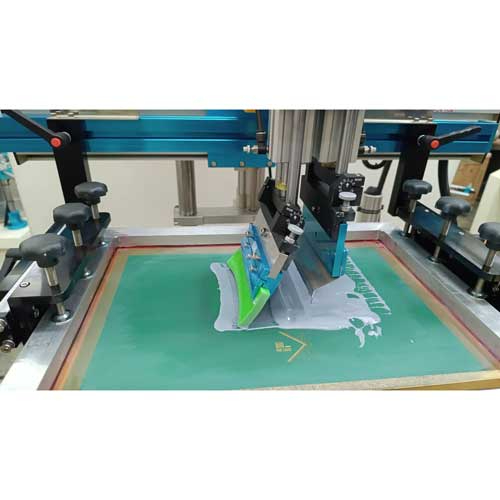

Pneumatic Squeegee Holder (Vertical Movement)

-

Eliminates misalignment issues caused by manual lifting.

-

Reduces ink spillage and squeegee misalignment issues. Enables faster cleaning and more consistent placement.

Patented Magnetic Squeegee Clamp (Patent No. M390871)

-

Magnetic clamping design allows for quick and secure installation. Squeegee position can be easily adjusted by sliding.

-

Precision linear guides offer stable and accurate support for consistent ink application.

-

The printing system features servo motor control, linear guides, and ball screw drive, with digitally defined squeegee stroke positions and support for seamless 360° printing.

Smart HMI Control System

-

7-inch Color TFT Touchscreen

-

Multilingual interface: Traditional Chinese, English, Indonesian, Vietnamese, Thai

-

Sensor mapping and real-time position feedback for intuitive operation

-

PLC-based controller for easy expansion and customization

-

Scrolling text alerts for quick error identification

-

Electronic pressure monitoring with automatic fault detection display

Intelligent Printing Management

-

Track and manage squeegee/screen usage with auto-stop and maintenance reminders

-

Save multiple printing parameter sets for fast reciepe switching

-

Production History Analysis: with bar chart display for the past 30 days of

-

Productiviy

-

Runtime

-

Production speed

-

WiFi Connectivity (Optional)

-

Optional WiFi module allows connection to the Fine Cause App, enabling real-time monitoring of production status— anytime, anywhere.

Specifications

| Model / Specifications | FA-400RSM-CY |

|---|---|

| Printing Colors | 1 |

| Productivity/ Hour | 600~1800 |

| Machine Dimensions (cm) | L:90 W:80 H:190 |

| Air Pressure (kg/cm² / psi) | 4~6 |

| Power Consumption (A) | 5A |

| Power Supply (V) | 220V,single phase |

| Maximum Printing Area (mm) | 300x300 |

| Left-Right Stroke (mm) | 400 |

| Screen Stencil Lifting Height (mm) | 0~150 |

| Maximum Screen Screen Stencil Size (cm) | 50*72 |

| Screen Stencil Front-Back Adjustment (mm) | ±25 |

| Table Left-Right Adjustment (mm) | ±8 |

| Table Tilt Adjustment (Left-Right) | 10 degree /50 mm |

| Squeegee Holder Lift Distance (mm) | |

| Machine Weight | 211KG |

Videos

-

Servo-Driven Rotary Screen Printing Machine-(With Color Sensor Registration & Custom Fixtures)-FA-400RSM-CY

Servo-Driven Rotary Screen Printing Machine-(With Color Sensor Registration & Custom Fixtures)-FA-400RSM-CY

-

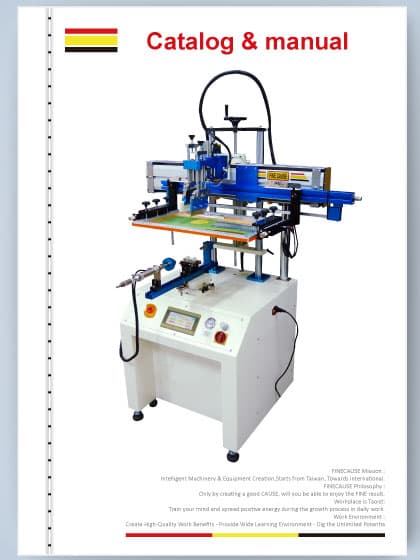

Screen Printing Machine w/ Servo Motor and Curved Printing, w/o Automatic Postitioning Device-FA-500RSM

Screen Printing Machine w/ Servo Motor and Curved Printing, w/o Automatic Postitioning Device-FA-500RSM

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

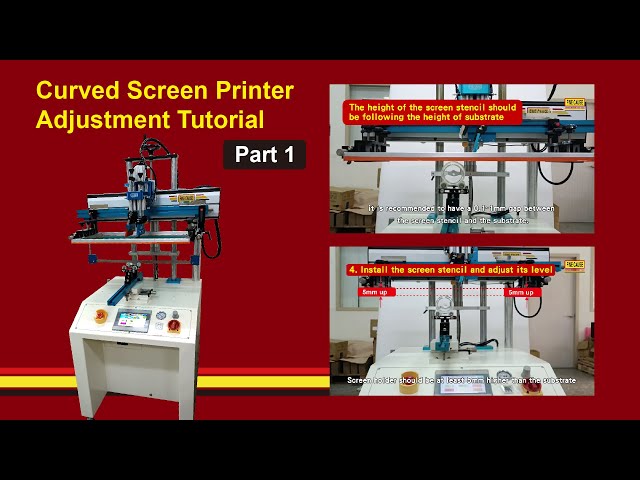

Curved screen printer tutorial video Part 1

Curved screen printer tutorial video Part 1

-

FA-400 RSN Semi automatic curved screen printer tutorial video Part-3

FA-400 RSN Semi automatic curved screen printer tutorial video Part-3

-

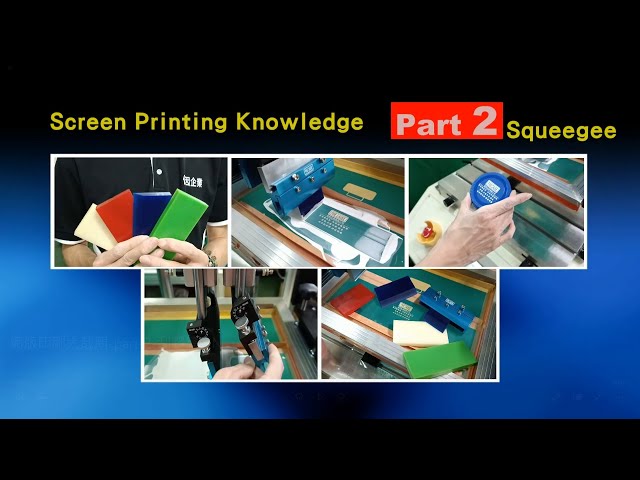

Screen Printing Knowledge-Part-2 Squeegee

Screen Printing Knowledge-Part-2 Squeegee

Downloads

-

Color Sensing Positioning Servo Motor Curved Screen Printer - FA-500RSM Catalog

Color Sensing Positioning Servo Motor Curved Screen Printer - FA-500RSM Catalog

Color Sensing Positioning Servo Motor Curved Screen Printer - FA-500RSM Catalog

-

FA-400 500 600RSN Curved Screen printing machine(Servo Motor)

FA-400 500 600RSN Curved Screen printing machine(Servo Motor)

FA-400 500 600RSN Curved Screen printing machine(Servo Motor)

-

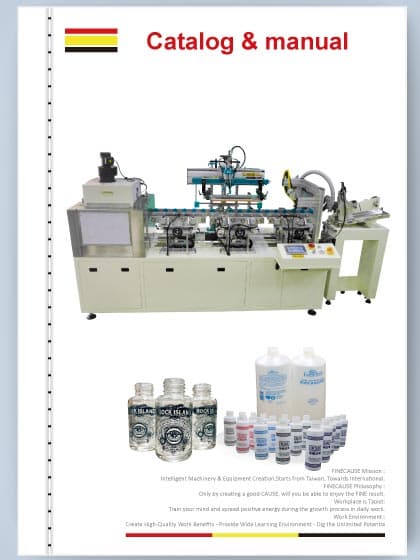

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

FA-LV3-bottle screen printing machine(flame + UV curing)3rd generation

-

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

-

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links