Products

RUCO series 937LED SCREEN PRINTING INK

RUCO series 937LED SCREEN PRINTING INK

Product Info

-

Universal free radical LED and conventional UV (Hg-, Fe-doped) curing high gloss 2-component screen printing ink for the printing of glass, metal and ceramics

-

Substrates may differ in their surface properties or method of manufacture. Therefore, a suitability test must always be carried out before printing

-

Antistatic, mould release agents and slip additives may have negative effects on adhesion, and should be detected and removed prior to printing

Characteristics

-

Universal free radical LED and conventional UV (Hg-, Fe-doped) curing high gloss 2-component screen printing ink for the printing of glass, metal and ceramics

-

The 937LED ink series is suitable for multi-colour inline printing and excels at their resistance against chemical and cosmetic agents as well as typical beverage industry liquids

-

Optimal adhesion and scratch resistance can be achieved within a shorter time compared to conventional UV curing ink series. Water and dishwasher resistance and ice water or frost resistance (up to -20°C) will be achieved only after approximately 72 hours (storage at room temperature)

-

If the storage temperature is less then 21 °C, the post curing effect will be reduced and the time to achieve the final properties and resistances is prolonged. A special product suitability test is recommended prior to production

-

RUCO series 937LED inks are suitable for the overall screen printing industries. The printing speed goes for 800-1600 pcs per hour

-

Many glass containers are cold end coated (CEC) in order to improve the scratch resistance and obtain a transport protection. Therefore, to achieve good ink adhesion onto glass, a flame, Pyrosil or UVITRO pretreatment of the glass surface is necessary. In dependence of different hot and cold end coatings a special product suitability test is recommended prior to production

-

Based to the high reactivity please avoid direct daylight

-

The inks of series 937LED are formulated for LED bulbs (irradiance: minimum 8W/cm²) of wavelength of 395 nm. Alternatively, you can use conventional UV curing bulbs (Hg- or Fe-doped with a lamp power of 160 – 200 W/cm, UV dose 200mJ/cm²). Series 937LED shows good curing properties and is suitable for more than 100 cycles/min. depending on the colour shade, UV bulb configuration, mesh count and transferred film weight

-

Please note that low radiation intensity, excessive machine speeds or excessive film thickness can have a negative influence on the curing properties and adhesion

-

The damage to the UV curing bulb or the size and shape of the refracting glass will likely affect the curing process and adhesion of the series of 937UV inks

-

Uncured prints are considered hazardous waste. Therefore, it is recommended to cure misprints under the UV bulb. After curing, waste can be disposed of by conventional methods

|

|

RUCO series 937LED SCREEN PRINTING INK

The ink has an ability of rapid volitilization speed which is suitable for pad printing on plastics, metal, glass, and lacquered surfaces, etc. For more details, please sned us a RFQ form. Our specialist will contact you soon.

|

Specifications

| Item |

RUCO series 937LED SCREEN PRINTING INK |

|---|---|

| Content (kg) | 1kg |

| Package | Can |

Comparison of Curing Methods

| Mercury UV lamp | LED UV lamp | Infrared lamp | |

|---|---|---|---|

| Power Consumption |

High energy- consuming and heating |

High energy- consuming and heating |

Power saving and non-heating |

| Space Requirement |

Large | Large | Small |

| Odor | Stinks (ventilation system required) | Stinks | Odorless |

| Product Life | Serviced every 1000-hours running | 6000hours | 20K hours |

| Exchangeable Light Tube |

Yes | Yes | No light tube |

| Preheating time | 2-10 mins. | 3-5mins. | 0 sec. |

| Light Source | Defocused | Defocused | Focused |

| Relative Weight | Heavy | Heavy | Very light |

| Budget | High | Medium | Most afforadable |

Videos

-

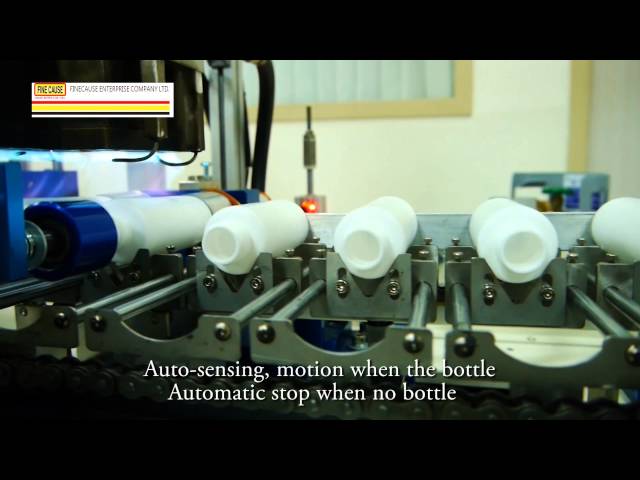

FA-LV1 Automatic Monochrome Curve Screen Printer Special for Silicone Filling Hose

FA-LV1 Automatic Monochrome Curve Screen Printer Special for Silicone Filling Hose

-

Clean Screen Printing Plate Tutorial

Clean Screen Printing Plate Tutorial

-

Automatic Rotating Mixer

Automatic Rotating Mixer

-

Magnetic Toolbox-(Magnetic Containers)

Magnetic Toolbox-(Magnetic Containers)

-

Corona Machine For Curved Surfaces

Corona Machine For Curved Surfaces

-

PP Material - Adhesion Test

PP Material - Adhesion Test

Downloads

-

TDS - 937UV-LED

TDS - 937UV-LED

TDS - 937UV-LED

-

MSDS_937UV-LED

MSDS_937UV-LED

MSDS_937UV-LED

-

RUCO inks - 937UV LED M series DM

RUCO inks - 937UV LED M series DM

RUCO inks - 937UV LED M series DM

-

RUCO inks exclusive agent certificate

RUCO inks exclusive agent certificate

RUCO inks exclusive agent certificate

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Silk screen knowledge

Silk screen knowledge

Silk screen knowledge

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links