Products

screen printing machine w/suction function

screen printing machine w/suction function

Product Info

Screen printing machine w/suction function-FA-400/500/600TSF

Fine Cause's Silk screen printing machine imported to industrial I.O.T., combine smart factory App, assist you to implement production management goals through synchronous monitoring

■ Feature:

-

The suction type function screen printer can fix the material without displacement.

-

This semi-automatic screen printer adopts servo motor design, ball screw and linear guide for ink scraping, movement stable, printing more accurate.

-

It's different with pneumatic cylinder type screen printer, will not generate ink leaking problem which affected by the air pressure and the left and right anti-collision buffers.

-

This suction screen printer adpots 7.0 inches multicolor color touch screen with 65536 colors TFT;The man-machine interface can be easily switched to select the language:English, Indonesian, Vietnamese ,Thai andTraditional Chinese.

-

Input & output full display

-

Abnormal warning display, convenient for quickly eliminate abnormalities

-

Digital pressure sensor, automatic alarm display for insufficient air pressure

-

Able to set the number of times which silk screen is used, and it will automatically stop and display inform when the number is arrives.

-

PLC Programmable Logic Controller easy to add and modify function

-

-

Servo ink Scraping System provide the entire scraping process able to control within a fine tolerance.

-

Silk screen printing stencil frame holder left-right moving by linear guide, smoothness and more precision than T-track.

-

Precise CNC machining assembly bushing up-down system attain high precision, easy to move up and down, stable and quiet.

-

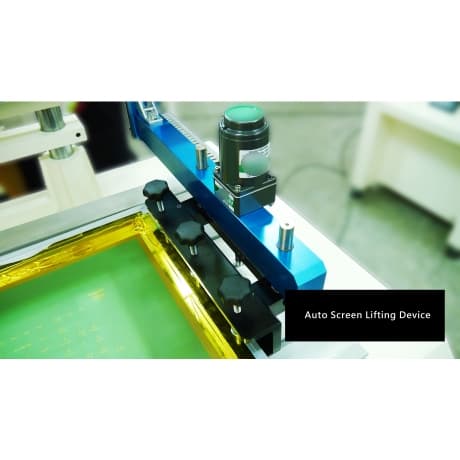

The lifting height of screen stencil is by digital control.

-

Digital lifting is set by HMI.

-

The air brake is adopt for screen stencil lifting.

-

The air brake is to use the circuit + air pressure mechanism to decelerate in advance before ascending and descending to the desired position; so as to achieve smoothness, reduce crash sound, and increase stability.

-

-

This screen printing machine does not use hydraulic buffer cylinders; so there is no need to replace the related parts, which saves consumables.

-

..For detailed introduction, please refer to this related video: Servo motor flat screen printing machine-Digital lifting / Air brake

-

-

Pneumatic Squeegees up down station

-

pressure adjustable

-

Easy to positioning squeegees, without height-offset or ink flow out problem comparing to traditional mechanism

-

More convenience to clean the silk screen

-

-

suction screen printing machine adopts a magnetic squeegee clip (Patent No. M390871) makes the squeegee position can be slided easily and is simple to adjust and disassemble.

-

Built in smart bar chart, production data displayed by graphs in the past 30 days. Connect with FineCause smart factory APP, no matter where you are, you can overview the production data of your silk screen printer.

-

Flat surface screen printng machine is able to install with disc divider, suction system, pressing positioning, pushing positioning, automatic load & unload mechanism, industrial cameras, actuators and other peripheral institutions.

■ Application :

Paper, PVC Membrane, Transfer Paper, Acrylic Printing.

【FineCause Advantage】

FineCause is professional silk screen printing machine, servo screen printing machine,flat surface screen Printing equipment, semi automatic screen Printing equipment, semi automatic screen printer and automatic silk screen printing machine manufacturer.

FineCause have imported Servo motor ink scarping system in 2016, component production adopted extrude integrally molded. Currently have the best price among whole Taiwan servo motor screen printer manufacturers.

FineCause silk screen printer already have a foothold and good reputation in Taiwan. We have a professional team to provide service at any time, please feel free to contact us if you’re interest to our machine or be our distributor.

Specifications

| Model | FA-400TSF | FA-500TSF | FA-600TSF |

|---|---|---|---|

| Color | 1 | 1 | 1 |

| Cycles/hr | 600~1800 | 600~1800 | 600~1800 |

| Machine Size (cm) | L:90 W:70 H:170 | L:100 W:70 H:170 | L:110 W:70 H:170 |

| Pressure(kg/cm2 psi) | 4~6 | 4~6 | 4~6 |

| Power (A)Ampere | 5A | 5A | 5A |

| Voltage (V) | 220V | 220V | 220V |

| Platform Size(mm) | 320*500 | 320*500 | 320*500 |

| Max Printing Area(mm) | 300*300 | 300*400 | 300*500 |

| Max. Height of Printed Object(mm) | 200 | 200 | 200 |

| Platform Moving Distance(mm) | 400 | 500 | 600 |

| Platform Height (mm) | 0~150 | 0~150 | 0~150 |

| Max. Screen Plate Size (cm) | 50*72 | 50*82 | 50*92 |

| Screen Plate Trimming Distance (mm) | ±25 | ±25 | ±25 |

| Platform Trimming Distance (mm) | ±8 | ±8 | ±8 |

| Platform Tilt Angle/ | 10/50 | 10/50 | 10/50 |

| Scraping Stand Lift Distance(mm) | |||

| Weight | 207 KG | 209 KG | 211 KG |

Videos

-

Clean Screen Printing Plate Tutorial

Clean Screen Printing Plate Tutorial

-

Automatic Ink Matching & Ink Adjusting Mixer

Automatic Ink Matching & Ink Adjusting Mixer

-

Magnetic Toolbox-(Magnetic Containers)

Magnetic Toolbox-(Magnetic Containers)

-

Automatic Rotating Mixer

Automatic Rotating Mixer

-

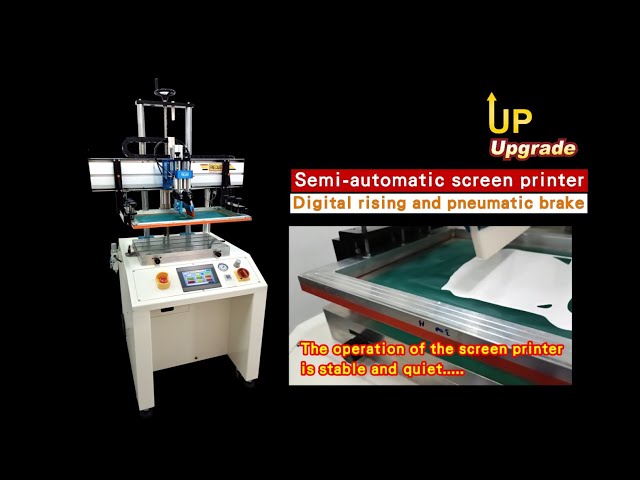

Semi-automatic screen printer upgrades with digital rising and pneumatic brake.

Semi-automatic screen printer upgrades with digital rising and pneumatic brake.

Downloads

-

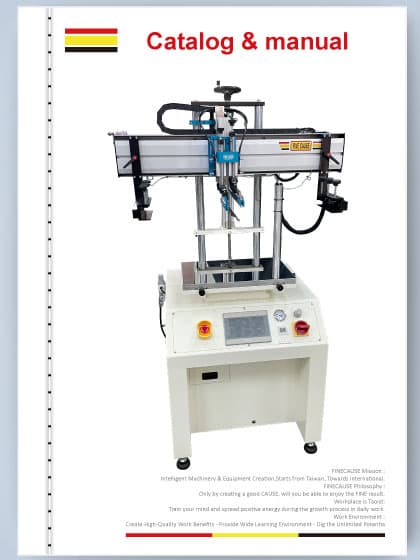

FA - 400/500/600TSF Servo Motor Screen Printer w/suction Function

FA - 400/500/600TSF Servo Motor Screen Printer w/suction Function

FA - 400/500/600TSF Servo Motor Screen Printer w/suction Function

-

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

-

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

CITD project research and development of Industry Bureau, Ministry of Economic Affairs

-

Silk screen knowledge

Silk screen knowledge

Silk screen knowledge

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links