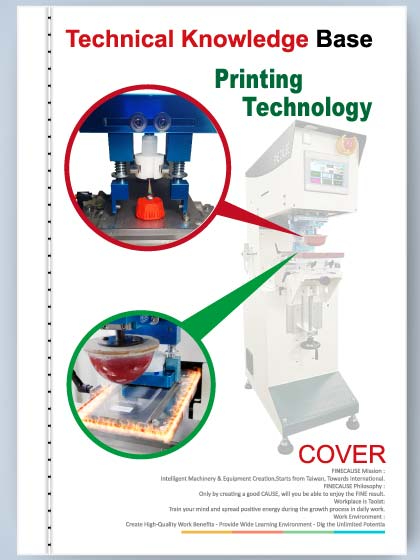

Products

Pad Printer (Ink cup Type)

Pad Printer (Ink cup Type)

Product Info

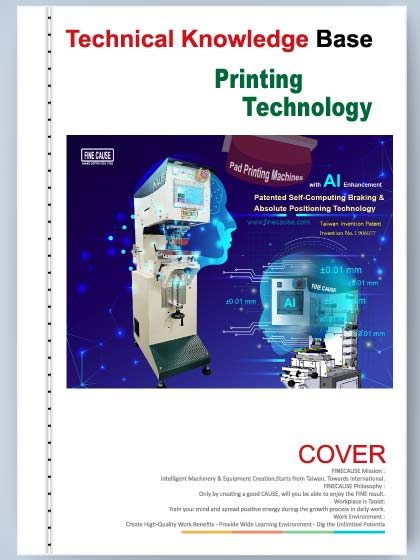

Pad printing, also known as Pad Printer technology, is a sophisticated gravure printing method designed for high-precision ink transfer.

By integrating two national-level invention patents, our pad printers are no longer passive executors.

They actively perform self-computation and maintain absolute positioning, ensuring consistent accuracy regardless of speed, air pressure, or environment.

This is a pad printer that “calculates how to stop” and “ensures zero deviation” on its own.

..Learn more about the complete introduction to Pad Printer with AI: Patented Self-Computing Braking & Absolute Positioning Technology...

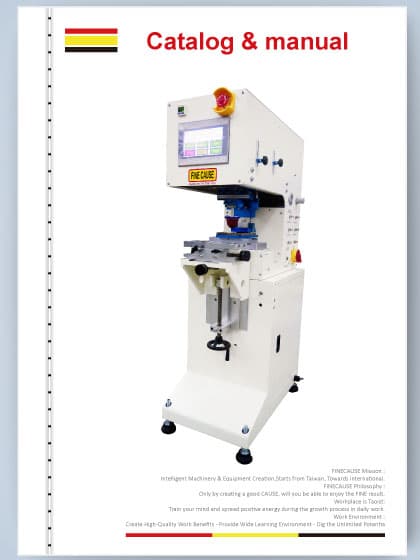

FC-161ANC

Pad Printer (Ink cup Type)

Precision Engineered for Excellence

The FC-161ANC Pad Printer by Finecause is a benchmark in precision engineering, designed to deliver stable, clean, and consistent ink transfer for flawless printing results. This ink cup type machine is perfectly suited for small to medium printing areas and is extensively applied in industries demanding high-definition and repeatable printing outcomes, including toys, electronics, metal parts, and decorative products.

Main Features of the FC-161ANC Pad Printer:

-

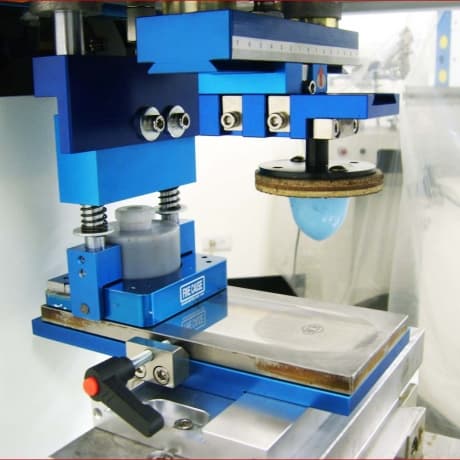

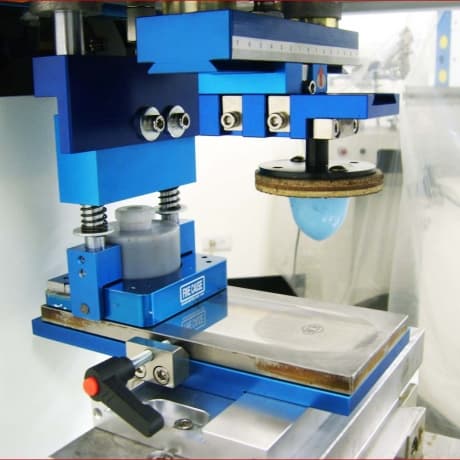

Precision Motion Components: Equipped with CNC-machined front and rear bushing assemblies, ensuring exceptionally smooth and accurate movement throughout the printing cycle.

-

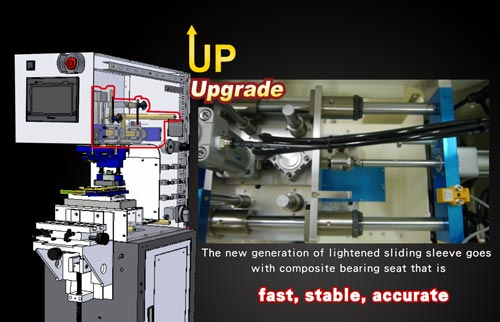

Advanced Sliding System: Features lightweight composite bearing seats for faster and more stable operation.

-

Clean & Efficient Ink Transfer: Specifically engineered to prevent unwanted ink residues, ensuring every print is clean, sharp, and consistent.

-

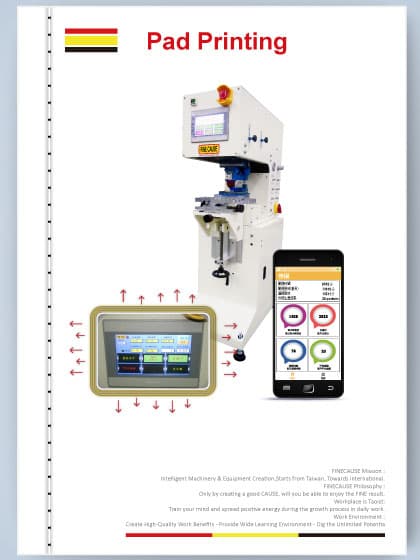

User-Friendly 7” Touchscreen: An upgraded, full-color 7-inch touchscreen with PLC control provides an intuitive and easy-to-navigate interface.

-

Multilingual Interface: Supports English, Traditional Chinese, Vietnamese, Indonesian, and Thai, catering to a global workforce.

-

Smart Dashboard System: Offers real-time display of crucial production metrics, including run time, speed, and output, for efficient monitoring.

-

Optional App Connectivity: Compatible with the Finecause App, allowing for remote monitoring of productivity and report generation from anywhere.

-

Robust & Safe Design:

-

Integrated computer sheet metal machine body with powder coating (Patent M453283) ensures exceptional sturdiness and durability.

-

Built-in electronic air pressure detection with automatic error alarms and text warnings for operational safety.

-

Production management tools allow setting usage limits for pads, ink cups, and plates, with automatic stops and reminders upon reaching preset values.

-

-

Clear Sensor Labeling: Input/Output sensor areas are clearly marked for convenient maintenance and quick troubleshooting.

-

Dynamic Anomaly Display: Error conditions are displayed as a "marquee" on the screen, enabling immediate issue resolution on the production line.

-

Configurable Printing Parameters: Pad action times are adjustable via the HMI, supporting various printing parameters and multiple recipe storage for quick switching between jobs.

Smart Ink Control System:

-

Programmable Settings: Offers programmable ink pickup frequency and pressure time, alongside adjustable ink thickness, making it ideal for diverse applications, including fabric printing.

-

Leak-Free Magnetic Ink Cup: Features a durable magnetic ink cup ring that works in conjunction with the doctor blade ring for a completely leak-free operation and tool-free maintenance.

-

Patented Adaptive Doctoring System (M311585): Provides precise adjustment of ink pressure for optimal results.

-

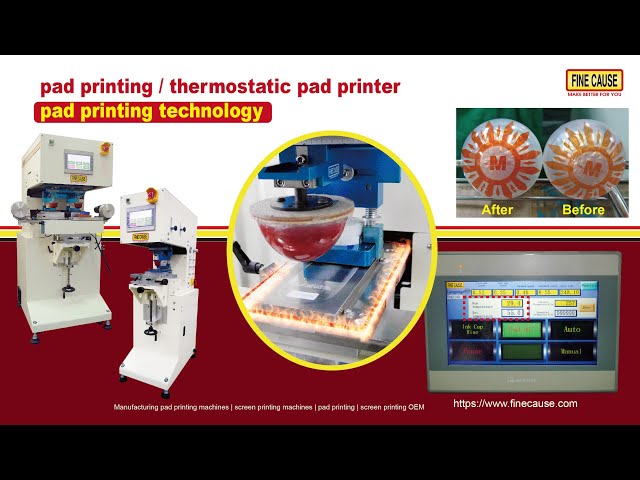

Optional Thermostatic Ink Control System: Upgrade your machine with Finecause's temperature control system to maintain stable ink temperature and consistent viscosity. This significantly enhances print quality and prevents common defects such as thin ink layers (color variation), inconsistent ink transfer (missing print areas), and premature ink drying (fraying or fading) during long printing runs. Thermostatic pad printing represents the future of high-end precision printing.

[Understand the benefits of Thermostatic Pad Printer for consistent quality.]

Enhanced Pad Motion System:

-

Adjustable Pad Pressure & Speed: Allows for fine-tuning of pad pressure and movement speed to match specific printing requirements.

-

Air Control Safety Mechanism: A critical safety feature that prevents the printing pad from dropping, protecting its integrity in the event of errors or misoperations.

Versatile Applications of the FC-161ANC Pad Printer

The FC-161ANC Pad Printer is suitable for high-quality printing on an extensive range of materials and irregular surfaces, showcasing its immense versatility across various industries:

-

Plastic Products: Toys, stationery, electronic casings, switches, and buttons.

-

Metal Components: Jewelry, watch faces, lighter surfaces, finished or semi-finished metal parts.

-

Ceramics and Glass: Decorative items, industrial components.

-

Other Textured or Curved Substrates: Any item with an uneven or complex surface profile.

Expandability and Optional Add-ons for Enhanced Efficiency

To further boost production efficiency and accuracy, the FC-161ANC offers a range of optional add-ons and automation compatibility:

-

Precision Indexing Plates: For improved material handling and positioning accuracy.

-

Automation Modules & Peripherals: Seamless integration with slides, rotary tables, oval tables, suction devices, flip modules, rotating platforms, and dryer racks to build fully automated production lines.

-

Thin Steel Plate Systems: Enhances efficiency for specific printing requirements.

-

Thermostatic Printing System: Can be added to maintain stable ink detachment and ensure print quality is unaffected by ambient temperature.

FAQ – Common Questions about Pad Printers (Click on the title link to watch the instructional video.)

1.How do I install the ink cup on my Pad Printer?

When assembling the ink cup and the steel plate, proceed gently and carefully. This prevents potential damage to the doctor blade ring, which could compromise its scraping effectiveness.

2. What is the recommended cleaning process for the ink cup?

To clean the ink cup, follow these six steps in sequence:

-

Remove the printing plate.

-

Empty any remaining ink.

-

Clean the inside of the cup.

-

Clean the outer doctoring ring.

-

Clean the inner doctoring ring.

-

Wipe the cup body clean using a cleaning agent and a soft cloth. Recommended tools include plate cleaner, chopsticks, and a cloth.

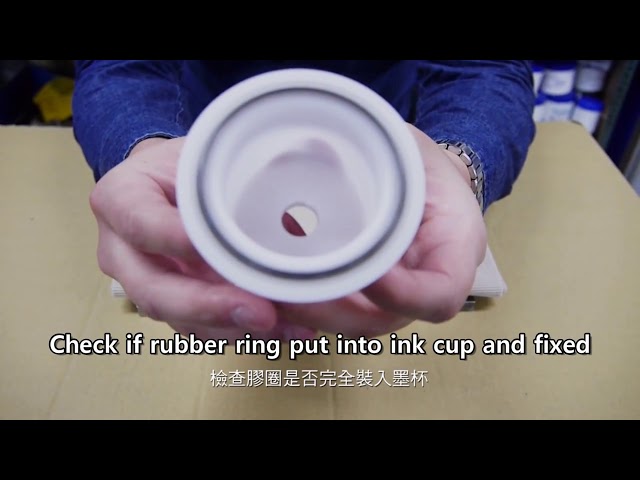

3. How do I assemble or replace the doctor blade ring?

- Before installing the doctor blade ring, always inspect it for any nicks or damage. This crucial check helps prevent scraping failures during operation.

In addition to pad printing machines with 60Ø ink cups, there are also models with 90Ø and 130Ø ink cups.

Click on the link to see various standard pad printer(semi automatic pad printer):

https://www.finecause.com/products/category1

Specifications

| Model | Color | Steel Plate (mm) | Capacity/hr | Dimension (cm) | Net W. |

|---|---|---|---|---|---|

| FC-161ANC | 1 | L:200 W:90 H:10 | 1200~1800 Pcs | L:75 W:45 H:135 | 105 Kgs |

| Model/Spec. | FC-161BNC | FC-161DNC Mini | FC-161ANC | FC-161CNC | FC-191ANC |

|---|---|---|---|---|---|

| Single-Color | Single-Color | Single-Color | Horizontal Scraping | Single-Color | |

| Ink-Cup Pad-Printer | Ink-Cup Pad-Printer | Ink-Cup Pad-Printer | Single-Color | Ink-Cup Pad-Printer-90Ø | |

| Ink-Cup Pad-Printer | |||||

| Air Pressure | 4~6 | 4~6 | 4~6 | 4~6 | 4~6 |

| Power Consumption (A) |

3 | 3 | 3 | 3 | 3 |

| Voltage (V) |

110-220V | 110-220V | 110-220V | 110-220V | 110-220V |

| Platform Size (mm) |

60*110 | 80*220 | 80*220 | 80*220 | 80*220 |

| Max. Print Area (mm) |

Ø50 | Ø50 | Ø50 | 170*50 | Ø75 |

| Max. Height ofPrinted Object (mm) |

120 | 180 | 180 | 180 | 180 |

| Platform Moving Distance (mm) |

125 (Front/Back) |

125 (Front/Back) |

125 (Front/Back) |

160 (Left to Right) |

125 (Front/Back) |

| Height -Pad Stand to Steel Plate (mm) |

94 | 94 | 100 | 100 | 100 |

| Max.Steel Plate Size (mm) |

90*200 | 90*200 | 90*200 | 80*350 | 120*240 |

Videos

-

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

-

Do you often have these printing issues?

Do you often have these printing issues?

-

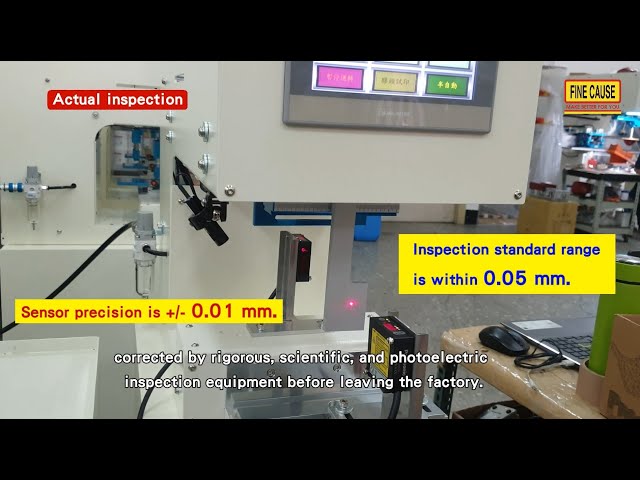

Pad printing machine precision inspection before leaving the factory

Pad printing machine precision inspection before leaving the factory

-

Pad Printing Machine by Temp-control

Pad Printing Machine by Temp-control

-

Instructions -Pad printer machine Knife Ring Tutorial

Instructions -Pad printer machine Knife Ring Tutorial

Downloads

-

Pad Printer Technology: Thermostatic Pad Printing Machine Meets the Automatic Solvent Adding System

Pad Printer Technology: Thermostatic Pad Printing Machine Meets the Automatic Solvent Adding System

Pad Printer Technology: Thermostatic Pad Printing Machine Meets the Automatic Solvent Adding System

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

-

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

Pad Printer with AI: Patented Positioning Printing Technology

Pad Printer with AI: Patented Positioning Printing Technology

Pad Printer with AI: Patented Positioning Printing Technology

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links