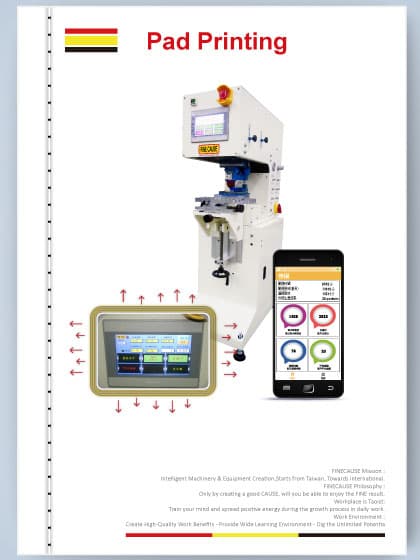

Products

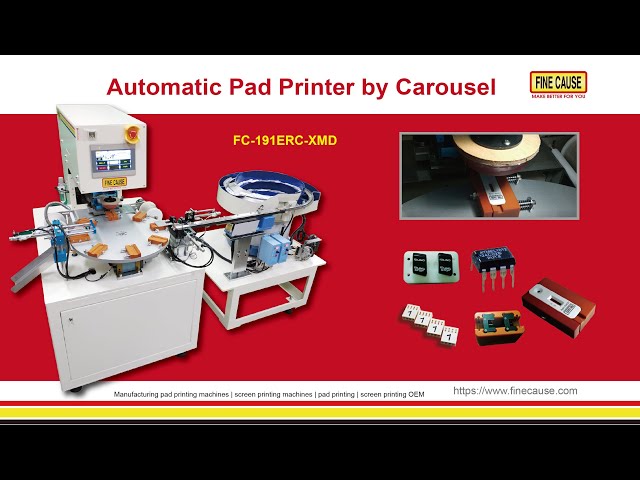

FC-191ERC-XMD

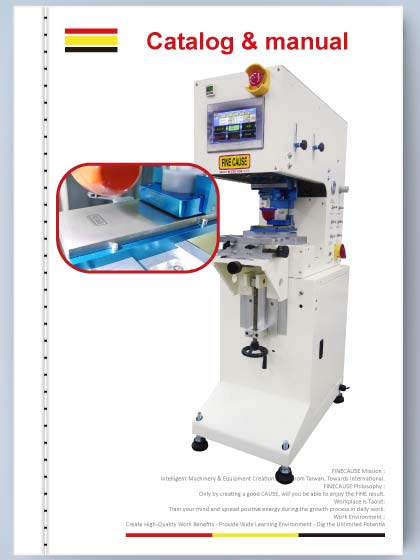

Fully automatic pad printer by Rotary indexing

FC-191ERC-XMD

Fully automatic pad printer by Rotary indexing

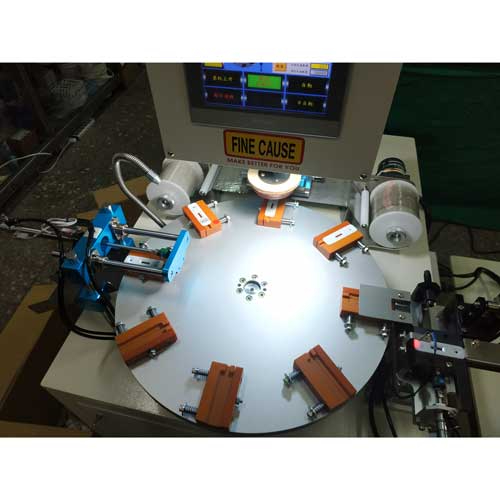

As long as the objects are poured into the vibratory bowl feeder, the automatic pad printer is fully automatic from feeding to discharging. Inductive flat feeding mechanism is to transfer the feeding objects. Pushing arm feeds automatically. The pad cleaning mechanism cleans the printing pad automatically. Air blower is to dry the object surface. Multiple formula storage function. Automatic discharging robot arm by pneumatic cylinder takes out the printed product automatically.

Add RFQ

RFQ results

Product Info

FC-191ERC-XMD

Fully automatic pad printer by Rotary indexing

1-Color Automatic Pad Printer by Carousel (Including Pad Cleaning Mechanism)

■Pad printer feature:

- Vibratory bowl feeder.

- Match with variable frequency drive that the frequency and speed of vibratory bowl feeder is adjustable.

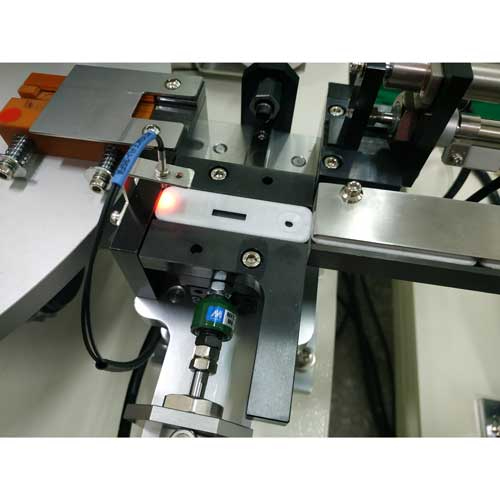

- Inductive flat feeding mechanism is to transfer the feeding objects.

- Automatic push mechanism.

- Automatic feeding by pushing arm.

- Use Ø90mm ink cup.

- Pressure regulating ink scraping (Patent No. M311585)

- The ink cup doctoring pressure can be adjusted easily.

- Pad cleaning mechanism.

- After setting the function of pad cleaning, the device will clean the printing pad automatically after printing.

- The count of cleaning and the count of intervals can be set.

- Air blower - drying the object surface after printing.

- Automatic discharging robot arm by pneumatic cylinder.

- The discharging mechanism takes out the printed product automatically.

- 7" color touch screen

- Built-in 2 languages, English and Traditional Chinese.

- Adopt PLC that is easy to add or modify functions.

- With multiple sets of formula storage functions. Parameters can be set.

- Production history function: built-in smart bar chart that can show the producticity, running time, production speed, etc in the past 30 days.

- With wifi function that can match with FineCause APP. So the productivity report can be seen any time. If the factory has the needs of Industry 4.0 productivity control, it can also be used together as well.

- Precision 8-stations with indexing table.

- Combined bushings make the machine run more smoothly and stably and improve printing quality.

- Printing speed is adjustable. The printing process is fast and stable.

■Action process:

Pour the objects into the vibratory bowl feeder.→The objects are picked by vibratory bowl feeder. →The objects pass through the tidy mechanism and the sensor senses that the object is in place indeed. →The pushing arm feeds the object into the jig →Ttransferring by indexing table. →Printing. →The pad cleaning function is executed after printing. The device will clean the printing pad automatically. →Air blower is for objects surface drying. →Automatic discharging robot arm takes out the objects from the jig.

Specifications

| Model | FC-191ERC-XMD |

|---|---|

| Printing Color | 1 |

| Suggested Max. Printing Area | Ø80 mm |

| Cliché Size (mm) | L:120 * W:240 * H:10 |

| Productivity/Hour | 900 Pcs |

| Machine Size (cm) | W:133 * D:156 * H:175 cm |

| Net Weight | 700 KG |

Videos

-

1-Color Automatic Pad Printer by Carousel-FC-191ERC-XMD

1-Color Automatic Pad Printer by Carousel-FC-191ERC-XMD

-

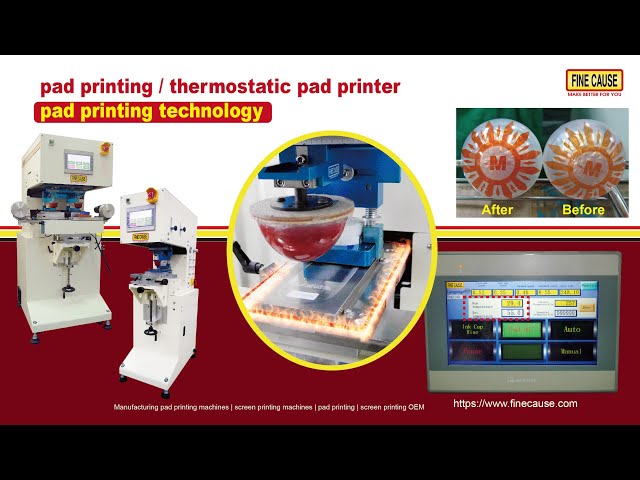

FC-162ERC Two-color Ink Cup Round Plate Pad Printer

FC-162ERC Two-color Ink Cup Round Plate Pad Printer

-

FC-161ANC-PD Automatic Monochrome Ink Cup Pad Printer - Operation Video

FC-161ANC-PD Automatic Monochrome Ink Cup Pad Printer - Operation Video

-

Do you often have these printing issues?

Do you often have these printing issues?

-

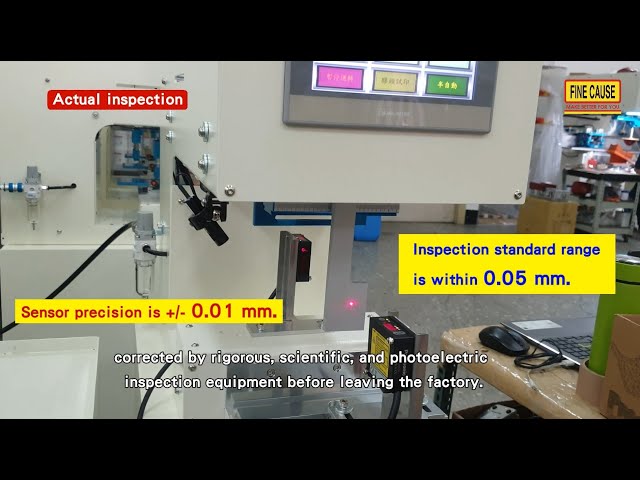

Pad printing machine precision inspection before leaving the factory

Pad printing machine precision inspection before leaving the factory

Downloads

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

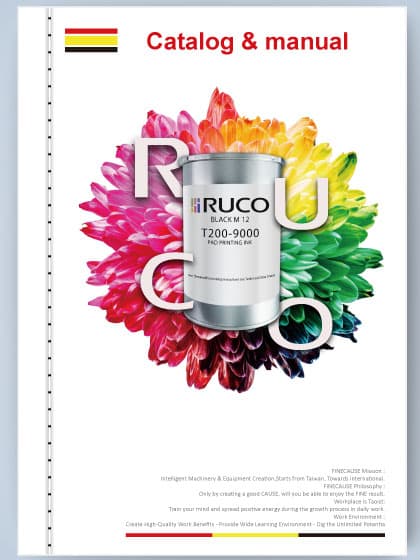

German RUCO ink series

German RUCO ink series

German RUCO ink series

-

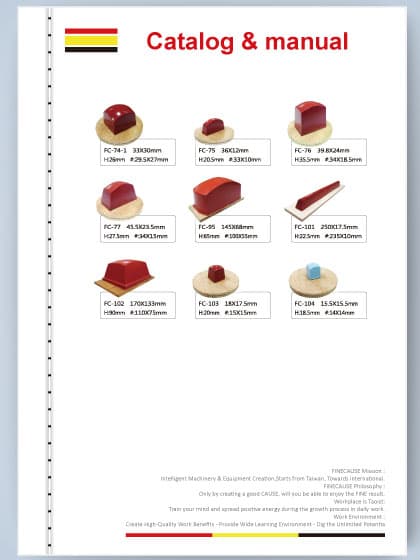

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

×

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links