Products

Tagless Label Printing/Tagless Pad Printing Machine

Tagless Label Printing/Tagless Pad Printing Machine

Product Info

Tagless Label Printing / Tagless Pad Printing Machine

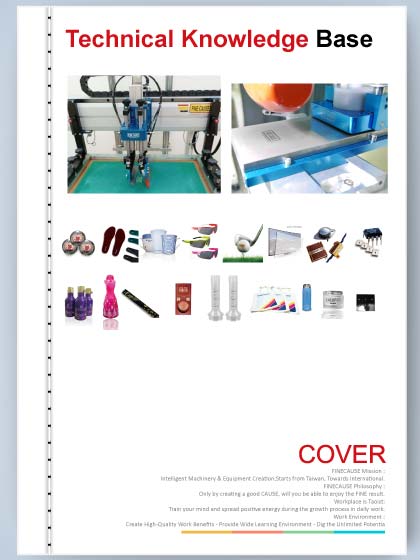

■ What is tagless label printing?

Tagless label printing is to print the label directly onto a garment or fabric rather than sew a fabric label into them.

Traditionally, fabric labels should be ordered and then sewn into garments, which makes the process long and variable. For example, the fabric label should be monitored closely for size inventory.

Traditional fabric labels will make infants, children, and most adults itchy, irritated, and uncomfortable. Most of the time, the important labels are cut from clothes by frustrated consumers.

Many apparel manufacturers are no longer used traditional fabric sewing labels and change to more cost-effective, sustainable and comfortable solution. Tagless label printing provides a simple and fast solution, which is able to reduce waste, lead time, and inventory. At present, most of the big, medium and small apparel companies are applying the tagless label printing in their production lines.

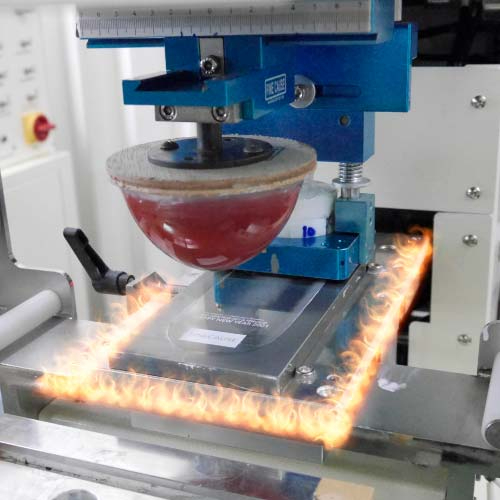

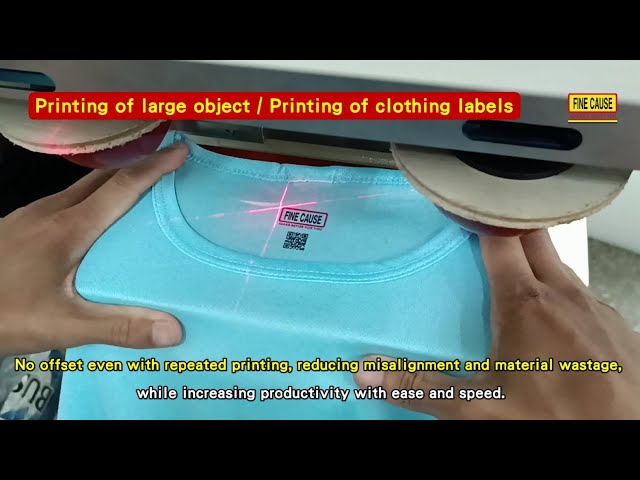

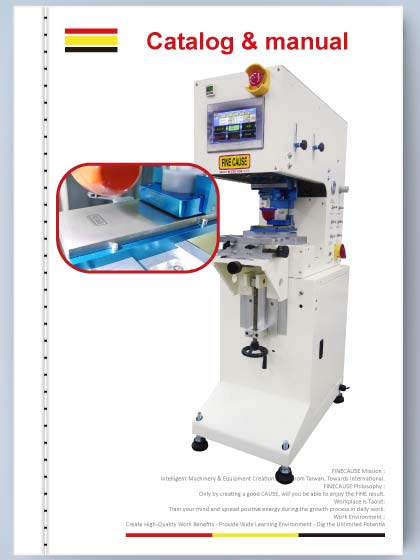

■ Suggested Tagless Pad Printer: FC-191ANC-CI semi automatic tagless pad printer (w/ cross red light laser pointer moudle)

The air cylinder for ink cup of this pad printing machine is independent. The ink cup air cylinder and silicone pad air cylinder are separated. They have their own air cylinder so that the ink cup and silicone pad are able to act independently (usually the same air cylinder is used to actuate). Apply 100X200mm cliche (can be customized according to needs). Equipped with laser crosshair reticle, which is convenient and fast to print according to the place where the infrared rays are irradiated.

Adopt pressure-regulating ink cup scraping/doctoring system (patent M311585), which is able to adjust the doctoring pressure of the ink cup easily. The new generation of lightened sliding sleeve goes with composite bearing seat that is fast, stable and accurate!…...click here for full introduction.

.............................................................................................................

■ Suggested Tagless Pad Printer: FC-192ASC

2-Color Tagless Label Printing Machine (Pad Printer with Pad Slide Mechanism)

Exclusive special design. During printing, the printing pad moves while the jig remains stationary that the color registration and alignment is more precise and the operation is easier. The object does not need to be moved during printing, allowing for dual-color printing. Equipped with a cross red light laser pointer that the printing process is able to be positioned conveniently and quickly based on the reference cross red light. Even printing novice can be easy to quickly get started. …...click here for full introduction.

■ Suggested Tagless Pad Printer: FC-191DNC LT semi automatic tagless pad printer

The price of this printer is relatively low and is economical and practical, which is suitable for low printing volume. A laser crosshair reticle is installed to make printing registration easier. With L-shaped casting and integration structure, the machine is sturdy and easy to operate. The body of the pad printer is enlarged, which is more stable during operation. This pad printing machine is able to equip with FineCause economical cliche module, which is the best choice for novice. …...click here for full introduction.

| Comparison of Apparel Label Production Methods | ||||

|---|---|---|---|---|

| Method | Tagless Label Printing | Fabric Label Sewn into Garment | Embroidered Label | Heat Transfers |

| Picture |  |

|

|

|

| Cost | Low | High | High | medium |

| Consuming Time | Short | Long | Long | Long |

| Realwear feeling | Excellent | Poor | Fair | Fair |

| (Soft and comfortable as usual) | (Will have itchy feeling) | (Will feel the thick line on the surface) | (Will be sticky after washing) | |

| Summary | The printing speed is fast. The ink can be dried immediately after printing without any drying treatment. Suitable for mass production. The average cost of printing is low. The touch of garment is still soft and comfortable after printing. The ink on the garment will not crack and deform after washing. | Fabric labels should be ordered and then sewn into garments, which makes the process long and variable. For example, the fabric label should be monitored closely for size inventory. | It's time-consuming, which is not suitable for mass production. In addition, graphic with thin lines are not able to achieve by this method. Sensitive people will feel the roughness of the embroidery. | At least 2 sets of equipment are required to proceed, including a printer and a heat press. Both of the equipment will increase energy consumption and generate lots of waste. Heat transfer labels are not durable. If to bend, stretch, or wash few times, the graphics will break and deform. |

Videos

-

FC-191ANC-CI-Pad printer w /Cross Red light Laser Pointer moudle and InkCup Cylinder independently

FC-191ANC-CI-Pad printer w /Cross Red light Laser Pointer moudle and InkCup Cylinder independently

-

FC-191DNC-LT Monochrome Ink Cup Pad Printing Machine

FC-191DNC-LT Monochrome Ink Cup Pad Printing Machine

-

FC-161BNC Monochrome Ink Cup Pad Printer - Operation Video

FC-161BNC Monochrome Ink Cup Pad Printer - Operation Video

-

2-Color Pad Printer with Pad Slide Mechanism (Tagless Label Printing Machine)-FC-192ASC

2-Color Pad Printer with Pad Slide Mechanism (Tagless Label Printing Machine)-FC-192ASC

-

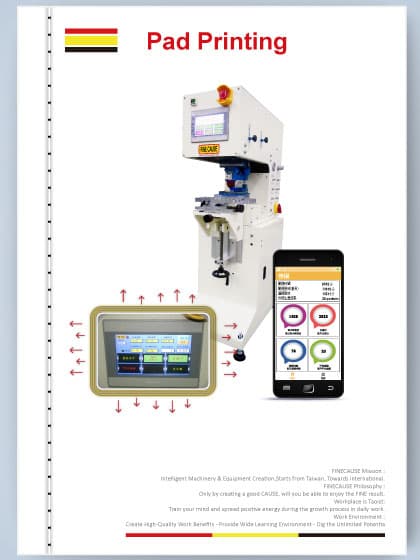

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

Downloads

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

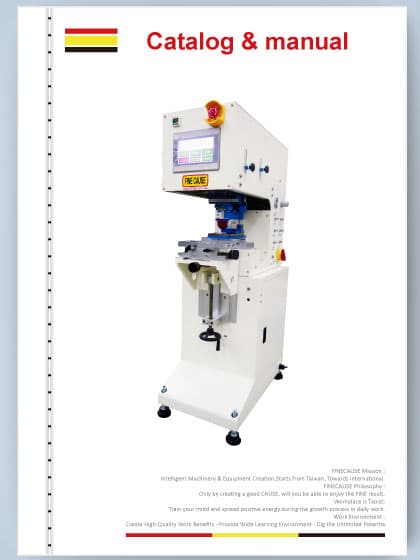

FC-191ANC Ink Cup Pad printing machine/Pad Printer DM

FC-191ANC Ink Cup Pad printing machine/Pad Printer DM

FC-191ANC Ink Cup Pad printing machine/Pad Printer DM

-

Pad printing technology

Pad printing technology

Pad printing technology

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

-

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

How to Select Pad-Print and Screen-Print

-

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

How to Select the Silicone Pad Printing Pads?

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links