Products

Bag Printing Machine with Automatic Rotary Mechanism

Bag Printing Machine with Automatic Rotary Mechanism

Product Info

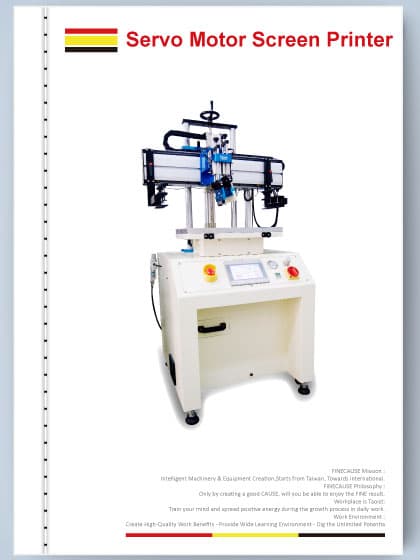

FA-400TSN-LR

Bag Printing Machine with Automatic Rotary Mechanism

■ Feature of screen printing machine:

-

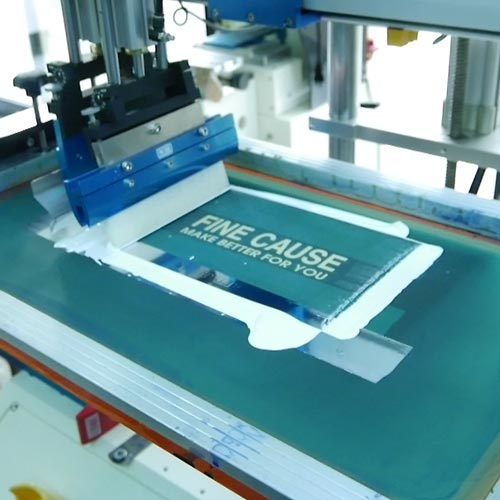

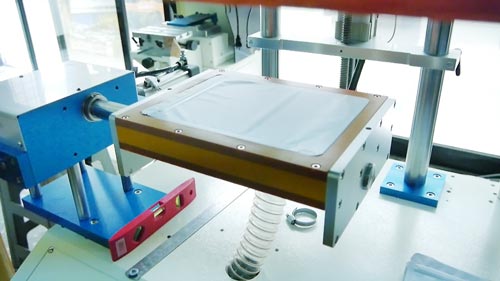

▼The screen printer is equipped with a rotary mechanism that the special printing jig for paper bags will automatically rotate and position the front and back sides printing.

-

-

To rotate or not to rotate can be chosen. (can do printing on one side or both sides)

-

The normal flat jig can be replaced. One printer can be used for 2 purposes.

-

-

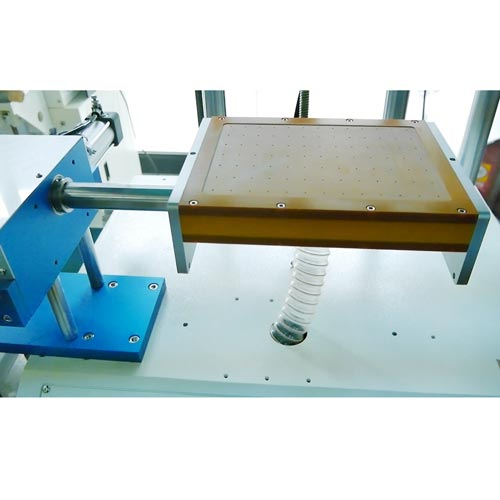

▼Equipped with a suction device (blower), the flat object can be fixed.

-

Adopt PLC that the functions is easy to add or modify.

-

The screen displays the servo running position. Multiple sets of formula can be stored and the parameters can be set.

-

-

Magnetic squeegee clip (Patent No. M390871)

-

Ink scraping adopts servo motor with linear guideway and ball screw rods.

-

The squeegee position can be slided easily and is simple to adjust the position and assemble and disassemble.

-

-

Pneumatic squeegee set lifts linearly.

-

There will no issue of squeegee height deviation, which will occur in traditional manual lifting.

-

It is more convenient to clean the screen stencil.

-

There will be no issue that the ink will flow out of the screen stencil, which will occur in manual squeegee lifting.

-

-

The upper and lower sleeves are extruded that the weight is reduced and the operation is fast, stable, and quiet.

-

Printing speed is adjustable. The printing process is fast and accurate.

-

7" color touch screen 65536 colors TFT.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

With abnormal alarm display, it is convenient for production line personnel to quickly eliminate abnormalities.

-

With electronic air pressure sensing, the device will alarm automatically for insufficient air pressure.

-

The usage count of squeegee or screen stencil can be set. When the set value is reached, the device will stop and notice automatically.

-

The HMI built-in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

-

The screen printer has the production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

The screen printer is combined with smart factory-Industrial Internet of Things (I.O.T.). Connect with FineCause smart factory APP, no matter where you are, you can view the produtivity report anytime and anywhere.

Specifications

| Model/Specification | FA-400TSN-LR |

|---|---|

| Printing Color | 1 |

| Productivity per Hour | 600~1000 |

| Machine Size (cm) | L:70*W:87*H:173 cm |

| Air Pressure (kg/cm2 psi) | 4~6 |

| Power Consumption (a) | 5A |

| Voltage (V) | 220V, Single Phase |

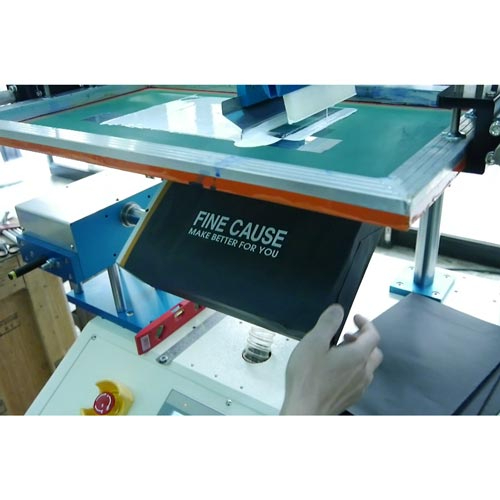

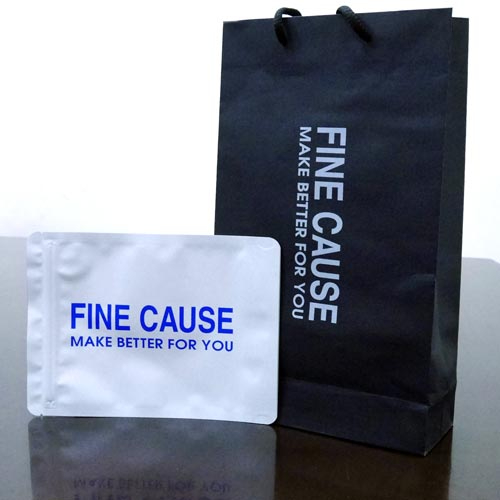

| Object Size (mm) | Paper Bag W:200*L:338 mm Aluminum Foil Bag W:160*L:217 mm |

| Allowable Object Height (mm) | 200 |

| Left and Right Stroke (mm) | 400 |

| Screen Stencil Peel Off Height (mm) | 0~150 |

| Max. Screen Stencil Size (cm) | 50*72 |

| Screen Stencil Front and Back Fine Tune Distance (mm) |

±25 |

| Platform Left and Right Fine Tune Distance (mm) |

±8 |

| Platform Left and Right Tilt Angle/ | 10°/50 |

| Lifting Distance of Independent Scraper Set (mm) |

|

| Net Weight (kg) | 205 KG |

Videos

-

Flat Screen Printer by Servo Motor + Rotary Mechanism/Suction Device (Blower)-FA-400TSN-LR

Flat Screen Printer by Servo Motor + Rotary Mechanism/Suction Device (Blower)-FA-400TSN-LR

-

FA-400TSN Screen Printer (including spin mechanism)

FA-400TSN Screen Printer (including spin mechanism)

-

Screen Printing Machine of Servo Motor, Platform and Spherical Type (Concave Printing)-FA-400TSN

Screen Printing Machine of Servo Motor, Platform and Spherical Type (Concave Printing)-FA-400TSN

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

-

Screen printing machines Fully Upgraded - Price remains unchanged

Screen printing machines Fully Upgraded - Price remains unchanged

Downloads

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

FINECAUSE 2020 Smart Servo Motor Screen Printer

-

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

-

Unitex Squeegees

Unitex Squeegees

Unitex Squeegees

-

The relationship between screen printing and printing

The relationship between screen printing and printing

The relationship between screen printing and printing

-

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links