Products

Electric Pad Printing Machine by Servo/Pad Printer

Electric Pad Printing Machine by Servo/Pad Printer

Product Info

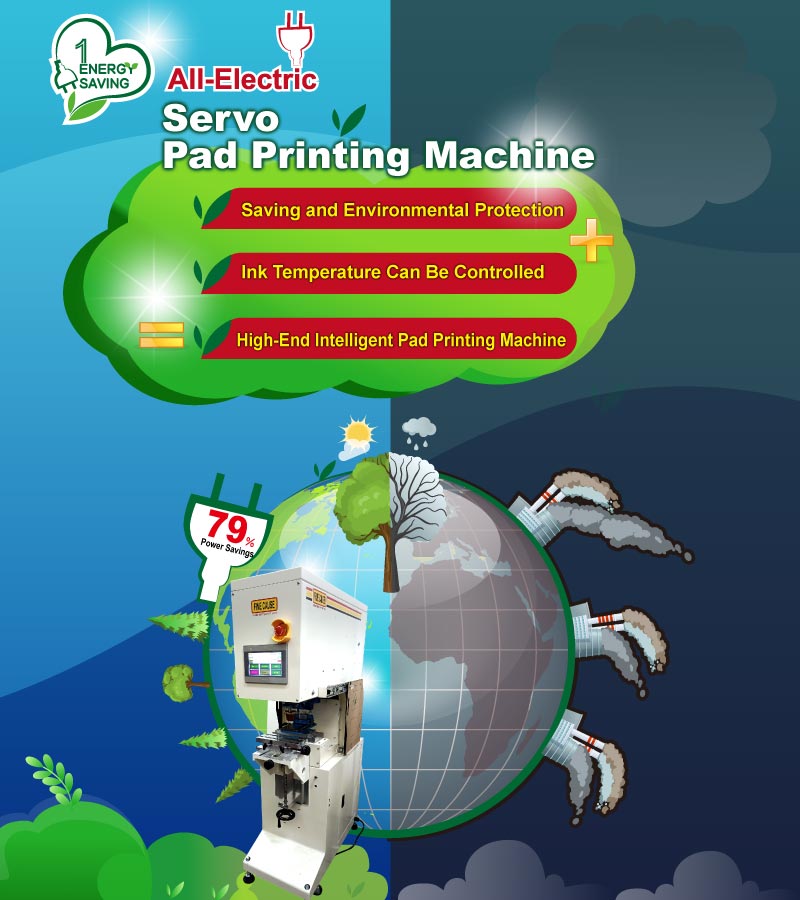

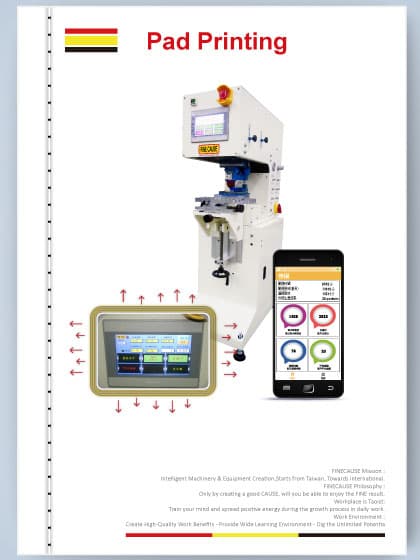

【Leading the Way in Eco-friendly and Energy-efficient High-precision Pad Printing Machines】 - FC-161ANS Fully Electric Servo Pad Printing Machine

Are you in search of a pad printing solution that not only provides precise printing but also champions energy efficiency and environmental sustainability? Look no further! Our state-of-the-art FC-161ANS servo-driven pad printing machine is set to revolutionize your printing processes.

Our FC-161ANS model leads the way in energy efficiency, saving up to 79.74% of electricity compared to traditional pneumatic systems. But that's not all.

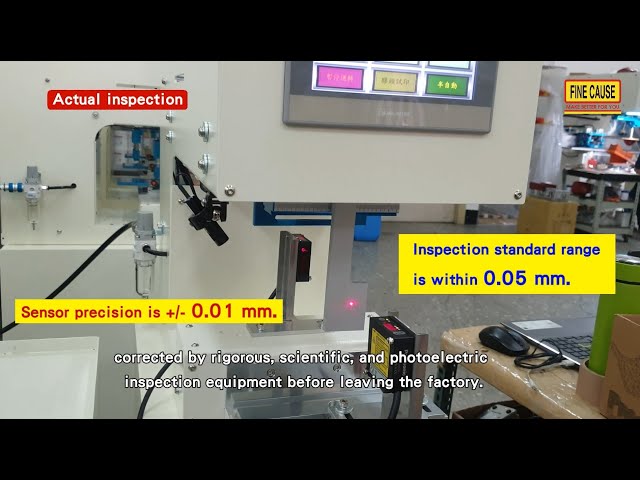

We further incorporate laser positioning technology to ensure mechanical positioning accuracy of 0.01mm or less. Energy conservation and carbon reduction not only reflect the current market trend but also align with today's advocacy for Environmental (E), Social Responsibility (S), and Corporate Governance (G).

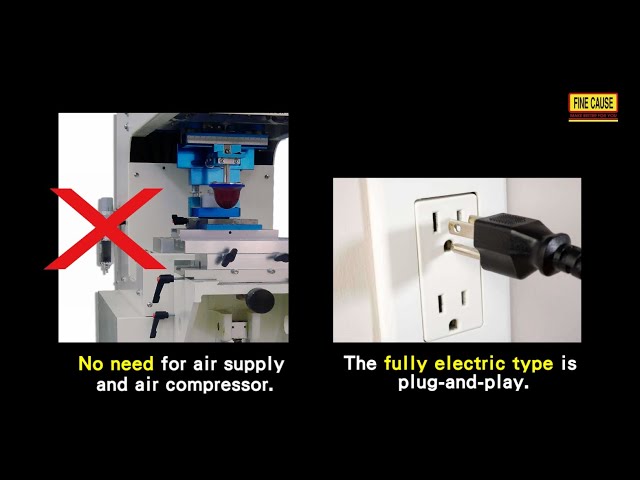

Why Choose a Fully Electric pad printing machine?

Because a fully electric pad printer doesn't require an air compressor! It can save nearly 80% of electricity! It's similar to choosing an inverter air conditioner because it saves significantly on electricity bills.

Although fully electric pad printers are more expensive than cylinder pad printers, they save a lot on electricity costs in the long run. No need for air connections, no heat exhaust issues, making it the best choice for your working environment and health!

Our Actual Test Results:

Energy consumption comparison between a traditional cylinder pad printing machine and a all electric pad printing machine shows that the all electric pad printing machine can save 79.74% of electricity.

★★★Assuming a monthly electricity bill of $1,000 USD,

■ you can save $797.40 USD every month.

■ You can save $9,568.80 USD in one year, and $28,706.40 USD in three years!

★★★Additionally, the pad printer comes with a three-year warranty.

😱😱😱Using a fully electric pad printer for three years is equivalent to earning the cost of 7 cylinder pad printers.

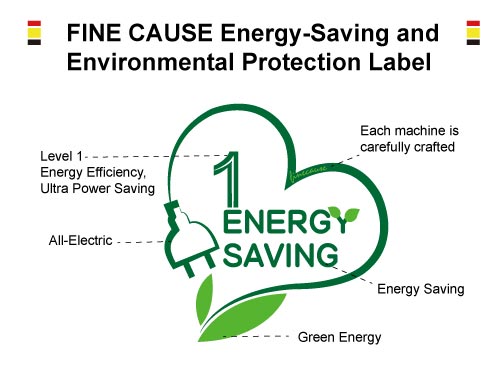

This fully electric pad printing machine not only excels in performance but also carries the FINECAUSE energy-saving and environmentally friendly certification, contributing to carbon footprint reduction and significant energy savings. By choosing our pad printing solution, you are not only investing in your business but also in a greener and more sustainable future. Moreover, with our machine requiring no large pneumatic systems, you can say goodbye to significant investments in air compressor equipment.

At FINECAUSE, we are committed to innovation, energy efficiency, and environmental responsibility. Join us on a journey of precision, energy saving, and intelligent technology, all wrapped in exceptional quality and design aesthetics. Experience the difference of the FC-161ANS pad printing machine - a perfect combination of performance, sustainability, and professional excellence.

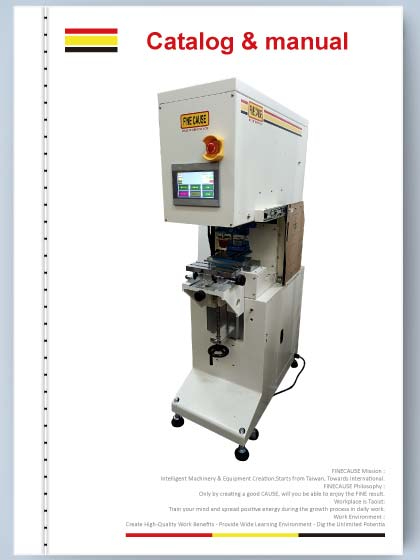

FC-161ANS Electric Servo Single Color Ink Cup Pad Printing Machine

-

The all electric pad printing machine is plug-and-play and does not require air connection and air compressor. It is suitable for printing in places without air compressor.

-

The printing pad adopts servo motors for the up, down, front, and back movements, unaffected by compressed air pressure.

-

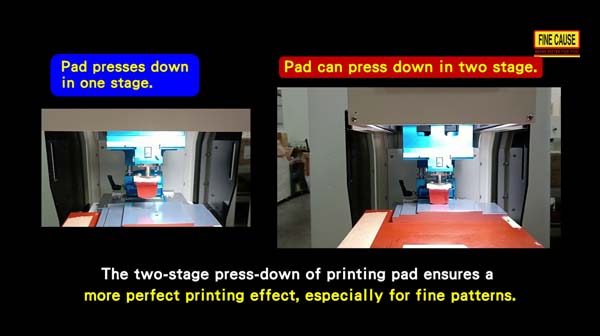

The pad printing pad can be pressed down in two stages.

-

The two-stage press-down of printing pad ensures a more perfect printing effect, especially for fine patterns.

-

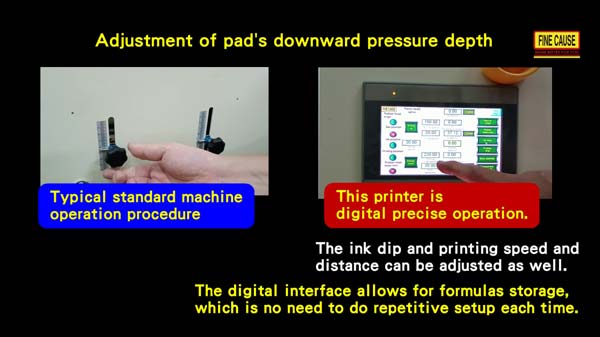

The Y+Z dual-axis servo drive printing pad for forward and backward movement and press down position. The control is through HMI for precise positioning and easy adjustment.

-

The HMI digital setting allows for formulas storage, which is no need to do repetitive setup each time; the various printing formulas can be 【switched quickly】. Printing in different positions and multiple items is fast and convenient.

-

-

Stepper pressure-regulating ink scraping system allows for easy adjustment of the downward pressure position of ink cup.

-

High-end version pad printer with precision and stability.

-

Servo-driven makes the machine operation smoother and more stable and significantly enhances printing quality.

-

7-inch TFT Color Touch Screen:

-

Built-in 5 languages, Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

Abnormal alarm display facilitates production line personnel to quickly eliminate abnormalities.

-

The usage times of printing pad and cliché can be set; when the preset count is reached, the machine will automatically stop and sound an alarm.

-

-

Utilizes a PLC (Programmable Logic Controller) for easy addition or modification of functions.

-

Built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With smart factory Industrial Internet of Things (I.O.T.), wherever you are, you can view the productivity report by downloading the FineCause APP.

-

Made by sheet metal + powder coating. The body is formed integrally.

-

A 3-year warranty is for this full electric pad printer.

-

Equipped with an electric safety door to reduce dust adhesion during printing.

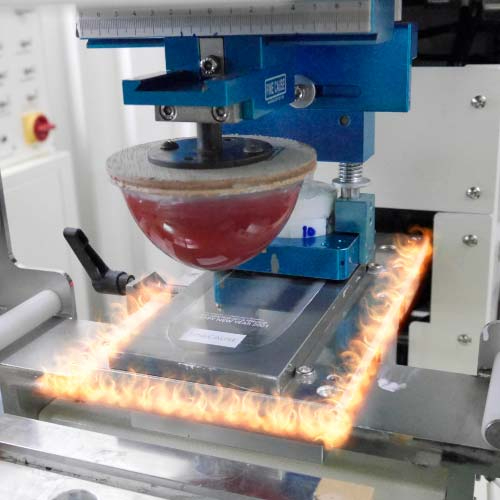

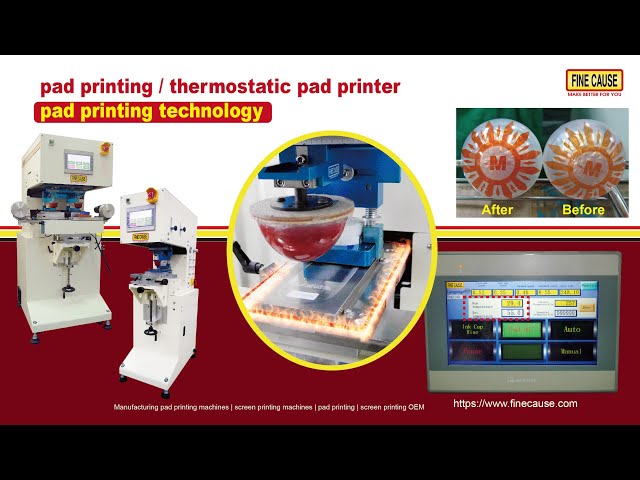

- A constant temperature printing system can be added to control the ink temperature. By using a constant temperature pad printing machine, the ink temperature can be controlled to achieve better printing results, increase the ink layer thickness, and ensure clean and smooth ink detachment. In the future, advanced pad printing machines will feature ink temperature control to improve issues like stringing. Raising the ink temperature during printing can promote faster evaporation during ink transfer, ensuring complete ink detachment and significantly enhancing coverage.

Specifications

Comparison Table of Energy Consumption between Traditional Cylinder Pad Printing Machine and Fully Electric Pad Printing Machine

Assuming 8 hours of work per day, approximately 22 working days per month, and 264 working days per year (excluding weekends and holidays).

| Model | Air Compressor Power (W) | Freeze Dryer Power (W) | Total Power Consumption (W) | Hourly Power Consumption (kWh) | Daily Power Consumption (kWh) | Monthly Power Consumption (kWh) | Annual Power Consumption (kWh) | Energy Ratio | Saved Electricity |

|---|---|---|---|---|---|---|---|---|---|

| FC-161ANC Cylinder Pad Printer |

2238 | 600 | 2838 | 2.838 | 22.704 | 499.488 | 5993.856 | 100% | 0% |

| FC-161ANS Fully Electric Pad Printer |

X | X | 575 | 0.575 | 4.6 | 101.2 | 1214.4 | 20.26% | 79.74% |

1 kWh = 1,000 watts per hour

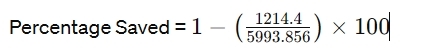

For FC-161ANS:

Annual power consumption of Cylinder Machine = 5993.856 kWh

Annual power consumption of Fully Electric Machine = 1214.4 kWh

Plugging these values into the formula:

Percentage Saved = 1 - (0.2026) × 100

Percentage Saved = 0.7974 × 100

Percentage Saved ≈ 79.74%

Energy consumption comparison between a traditional cylinder pad printer and a fully electric pad printer over the same period shows that the fully electric pad printer can save 79.74% of electricity.

| Model / Specification | FC-161ANS |

|---|---|

| Printing Color | 1 |

| Machine Size (cm) | L:85 W:42.5 H:149 cm |

| Productivity / hour | 1200~1800 pcs |

| Power Consumption (A) | 3 |

| Voltage (V) | 220V |

| Platform Size (mm) | 80*220 |

| Suggested Max. Printing Area (mm) | Ø50 |

| Max. Object Height (mm) | 180 |

| Front and Back Travel Distance (mm) | 125 |

| Height from Pad Holder to Cliché (mm) | 100 |

| Max. Cliché Size (mm) | 90*200 |

| Net Weight (kg) | 150 |

Videos

-

Pad printing machine Fully Upgraded - Price remains unchanged

Pad printing machine Fully Upgraded - Price remains unchanged

-

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

Ink Cup pad printing machine/Pad Printer Operation and Upgrade

-

Do you often have these printing issues?

Do you often have these printing issues?

-

Pad printing machine precision inspection before leaving the factory

Pad printing machine precision inspection before leaving the factory

-

Pad Printing Machine by Temp-control

Pad Printing Machine by Temp-control

-

Electric Servo Single Color Ink Cup Pad Printing Machine-FC-161ANS

Electric Servo Single Color Ink Cup Pad Printing Machine-FC-161ANS

Downloads

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

-

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

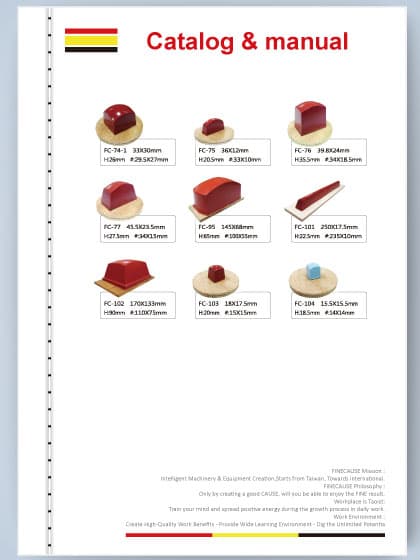

Pad Printer Accessories Catalog

Pad Printer Accessories Catalog

Pad Printer Accessories Catalog

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links