Products

Screen Printer | Screen Printing Machine by Precision

Screen Printer | Screen Printing Machine by Precision

Product Info

Advantages of Servo Motor Screen Printing Machine

Screen printing machines are indispensable manufacturing tools in modern production environments, capable of rapidly and accurately printing patterns or text on various materials. The semi-automatic servo motor screen printing machine represents a significant advancement in screen printing technology.

■ Higher Production Efficiency

The servo motor screen printer boasts superior automation features, contributing to its higher production efficiency. Unlike traditional screen printing machines that require manual intervention in various printing steps, the semi-automatic servo motor screen printing machine utilizes advanced servo motor technology to achieve partial automation. This results in a more stable printing process, reduces human errors, and significantly saves time, thereby greatly enhancing production efficiency.

■ More Precise Printing Quality

The quality of screen printing plays a crucial role in determining the final product's overall quality. The semi-automatic servo motor screen printer offers enhanced control capabilities, enabling more precise positioning of printing locations and pressure. This ensures consistent and highly accurate printing results for every print. Additionally, the machine is equipped with advanced sensors and monitoring systems, enabling real-time detection of any printing issues and immediate adjustments, reducing the occurrence of defects and improving product yield.

■ Convenient Operation and Maintenance

The design of the servo motor screen printing machine includes a simpler and more intuitive operating interface, facilitating quick learning and mastery of operation techniques by operators. Moreover, the machine's high level of automation reduces the complexity of maintenance and upkeep, as most maintenance tasks are performed by the machine itself. This not only saves time and effort for operators but also lowers maintenance costs.

■ Lower Energy Consumption

By adopting advanced servo motor technology, the servo motor screen printing machine achieves more efficient energy conversion compared to traditional electric motors, resulting in reduced energy consumption. Additionally, the machine comes equipped with an intelligent power-saving control system that automatically adjusts energy output based on actual printing demands, minimizing unnecessary energy wastage and making it more environmentally friendly.

■ Conclusion

The servo motor screen printer demonstrates evident advantages in screen printing technology. Its higher production efficiency, improved printing quality, convenient operation, and maintenance, as well as lower energy consumption, make it a wise choice for enterprises with extensive printing operations. It effectively enhances productivity and reduces overall costs.

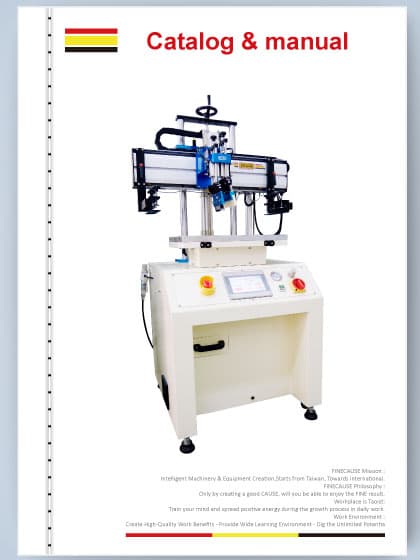

FA-400/500/600TSN

Screen Printer | Screen Printing Machine by Precision

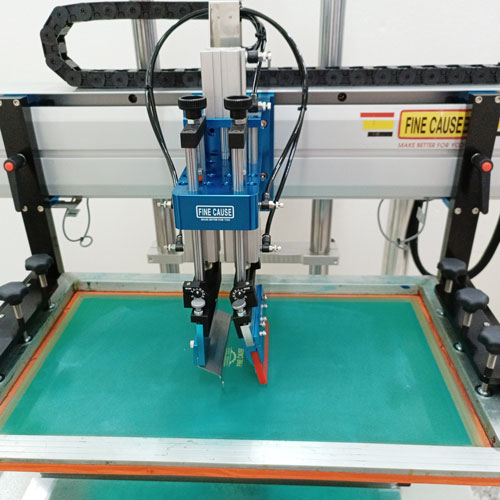

This screen printer adopts servo motor design. Using precise servo motor, ball screw and linear guide for ink scraping, movement stable, printing more accurate.

It's different with pneumatic cylinder type screen printer, will not generate ink leaking problem which affected by the air pressure and the left and right anti-collision buffers.

■ Screen printer feature:

-

7.0" HMI touch panel with 65536 color TFT, The man-machine interface can be easily switched to select the language:English, Indonesian, Vietnamese ,Thai andTraditional Chinese.

-

Input & output full display

-

Abnormal warning display, convenient for quickly eliminate abnormalities

-

Digital pressure sensor, automatic alarm display for insufficient air pressure

-

Able to set the number of times which silk screen is used, and it will automatically stop and display inform when the number is arrives.

-

PLC Programmable Logic Controller easy to add and modify function

-

-

Servo ink Scraping System provide the entire scraping process able to control within a fine tolerance.

-

Silk screen printing stencil frame holder left-right moving by linear guide, smoothness and more precision than T-track.

-

Precise CNC machining assembly bushing up-down system attain high precision, easy to move up and down, stable and quiet.

-

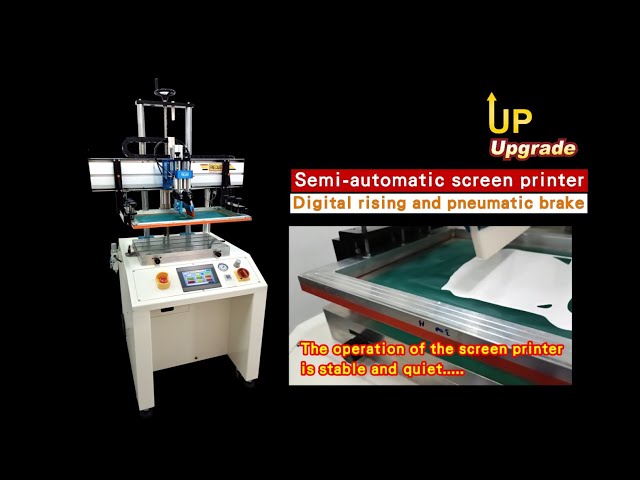

The lifting height of screen stencil is by digital control.

-

Digital lifting is set by HMI.

-

The air brake is adopt for screen stencil lifting.

-

The air brake is to use the circuit + air pressure mechanism to decelerate in advance before ascending and descending to the desired position; so as to achieve smoothness, reduce crash sound, and increase stability.

-

-

This screen printing machine does not use hydraulic buffer cylinders; so there is no need to replace the related parts, which saves consumables.

-

..For detailed introduction, please refer to this related video: Servo motor flat screen printing machine-Digital lifting / Air brake

-

-

Pneumatic Squeegees up down station

-

pressure adjustable

-

Easy to positioning squeegees, without height-offset or ink flow out problem comparing to traditional mechanism

-

More convenience to clean the silk screen

-

-

Flat screen printing machine adopts a magnetic squeegee clip (Patent No. M390871) makes the squeegee position can be slided easily and is simple to adjust and disassemble.

-

Built in smart bar chart, production data displayed by graphs in the past 30 days. Connect with FineCause smart factory APP, no matter where you are, you can overview the production data of your silk screen printer.

-

Flat surface screen printng machine is able to install with disc divider, suction system, pressing positioning, pushing positioning, automatic load & unload mechanism, industrial cameras, actuators and other peripheral institutions.

■ Suitable for the electronics industry that requires precision, applying solder paste or high-density glue to use.

Try it free for 14 days.

Trial available only in Taiwan.

| Screen Printer with Traditional Cylinder | Screen Printer with AC Motor | Servo Motor Screen Printer | |

|---|---|---|---|

| Pros and Cons | Pauses will occur when the left and right movement is stopped, which is easy to cause ink overflow. Due to the change of air pressure and resistance during doctoring, the speed of scraping will not able to be stabilized. Then cause the issue of inaccurate lines or ink overflow. | Part of scraping speed issue is solved. It will not be affected by air pressure; but the resistance during scraping still affects the speed. When proceeding the screen printing, more squeegee pressure will cause the AC motor speed slower by resistance. |

The speed will not affected by air pressure and resistance. The adjustable range is from 10mm/second to 1000mm/second and the accuracy of scraping distance can reach within 0.01mm. The printing quality and intelligent management are increased substantially due to digitized operation distance and speed. It will be a new generation of precision screen printer. |

| Application | With competitive price, it is often applied to traditional printing, electrical appliances, and shell of 3C products. | The adjustable range of speed is not large and the scraping speed and distance will not able to be digitized and precise. So it is outdated for new generation of industrial product applying. | It has a wide range of applications, such as general traditional printing, silver paste & solder paste coating printing, precision glass printing and other various screen printing, coating, and gluing. |

Which Silk Screen Printing Machine Should You Choose?

FineCause smart screen srinter

screen printer using precise servo motor movement stable movement stable, printing more accurate. screen printing easy to move up and down, stable and quiet. Silk screen printing stencil frame holder left-right moving by linear guide, smoothness and more precision than T-track.

Click on the link to see various screen printing machine(semi automatic screen printer):

https://www.finecause.com/products/category2

Automatic screen printing machine

https://www.finecause.com/products/category2/Customized-Screen-Printing-Machine

【FineCause Advantage】

Professional Screen Printers and Screen Printing Machine solutions engineered for precision-driven production.

Our comprehensive range of screen printers covers manual, semi-automatic, and automatic screen printing machine systems, suitable for flat surfaces, cylindrical objects, and complex industrial components.

Designed for manufacturers demanding stable print quality and consistent registration accuracy, each screen printing machine features precision linear guides, durable mechanical frames, and user-friendly operation. These screen printers are widely used in electronics printing, cosmetic containers, industrial parts marking, glass printing, plastic components, and packaging applications.

From prototyping to mass production, our screen printing machine solutions help improve productivity, reduce setup time, and maintain reliable printing consistency across every production cycle.

Specifications

| Model | FA-400TSN | FA-500TSN | FA-600TSN |

|---|---|---|---|

| Color | 1 | 1 | 1 |

| Cycles/hr | 600~1800 | 600~1800 | 600~1800 |

| Machine Size (cm) | L:70 W:87 H:173 | L:70 W:97 H:173 | L:70 W:107 H:173 |

| Pressure (kg/cm2 psi) |

4~6 | 4~6 | 4~6 |

| Power (A) Ampere |

5A | 5A | 5A |

| Voltage (V) | 220V | 220V | 220V |

| Platform Size(mm) | 320*500 | 320*500 | 320*500 |

| Max Printing Area(mm) | 300*300 | 300*400 | 300*500 |

| Max. Height of Printed Object(mm) |

200 | 200 | 200 |

| Platform Moving Distance(mm) | 400 | 500 | 600 |

| Platform Height (mm) | 0~150 | 0~150 | 0~150 |

| Max. Screen Plate Size (cm) | 50*72 | 50*82 | 50*92 |

| Screen Plate Trimming Distance (mm) | ±25 | ±25 | ±25 |

| Platform Trimming Distance (mm) | ±8 | ±8 | ±8 |

| Platform Tilt Angle/ Scraping Stand Lift Distance(mm) |

10/50 | 10/50 | 10/50 |

| Weight | 205 KG | 207 KG | 209 KG |

Videos

-

FA-400/500/600TSN Servo Motor Screen Printer - Operation Video

FA-400/500/600TSN Servo Motor Screen Printer - Operation Video

-

FA-400TSN Screen Printer (including spin mechanism)

FA-400TSN Screen Printer (including spin mechanism)

-

Clean Screen Printing Plate Tutorial

Clean Screen Printing Plate Tutorial

-

Screen printing machines Fully Upgraded - Price remains unchanged

Screen printing machines Fully Upgraded - Price remains unchanged

-

Servo Screen Printer + Air Suction Jig + Air Blower-FA-500TSN

Servo Screen Printer + Air Suction Jig + Air Blower-FA-500TSN

-

Semi-automatic screen printer upgrades with digital rising and pneumatic brake.

Semi-automatic screen printer upgrades with digital rising and pneumatic brake.

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

Downloads

-

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

Which Silk Screen Printing Machine Should You Choose? Pneumatic, Servo Motor, or Fully Electric Screen Printer?

-

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

FA-400 500 600TSN Semi Automatic Screen Printer-DM Download

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Unitex Squeegees

Unitex Squeegees

Unitex Squeegees

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

-

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

Examples of Screen-Print Related Parameters

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links