Products

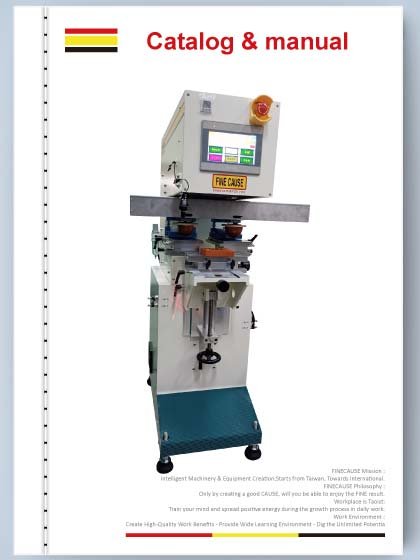

Two Color Pad Printing Machine with Rubber head Shuttling (Tagless Printing)

Two Color Pad Printing Machine with Rubber head Shuttling (Tagless Printing)

Product Info

▲ Optional customized flip jig for vertical printing and 90-degree rotation printing.

Two Color Pad Printing Machine with Rubber head Shuttling

(Tagless Printing)-FC-192ASC

-

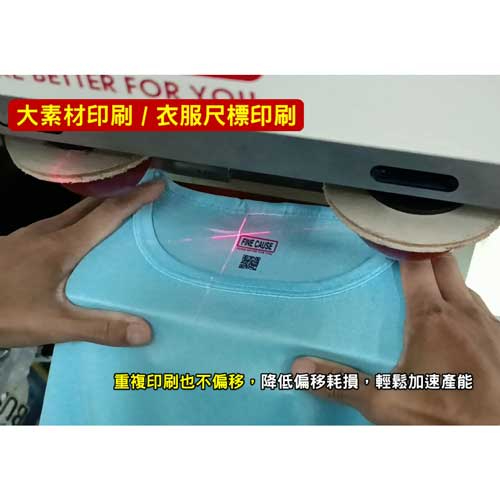

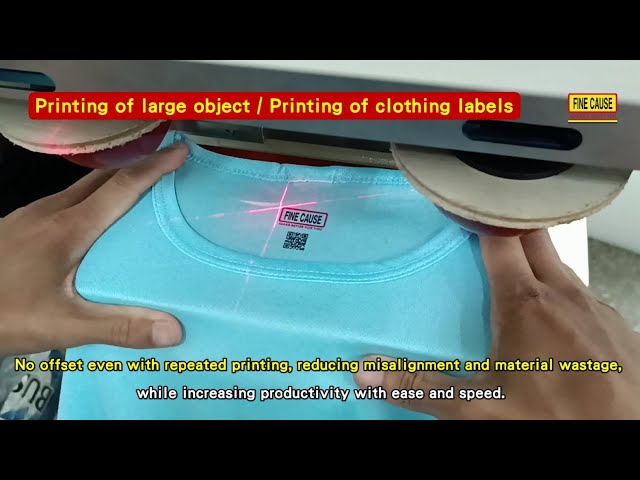

Exclusive special design: the 2 sets of printing pads on the pad printer have a center distance of 200mm. During printing, the printing pad on the right side moves 100mm to the left, while the printing pad on the left side moves 100mm to the right. This ensures that the printed object remains completely centered and immobile, even for large objects.

-

During printing, the printing pad move while the jig remains stationary, resulting in more precise color registration and alignment. This allows for easier operation.

-

When printing larger objects such as clothing labels or logo, positioning can be challenging. However, with this special design, you simply need to press and hold the object without moving it, and the machine will automatically complete the dual-color printing process.

-

-

Dual-seat adjustable steel plate holder is adjustable in the front, back, left, and right directions.

-

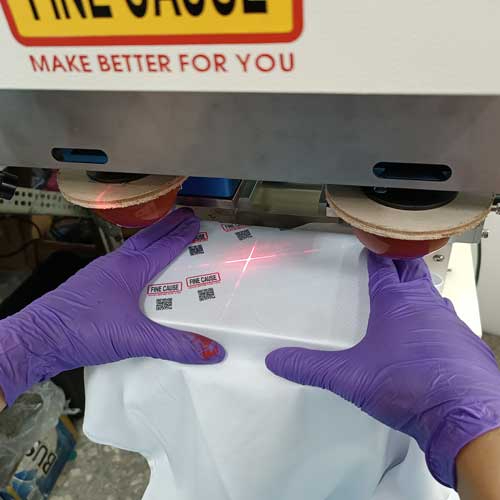

This pad printing machine can be equipped with a cross red light laser pointer, which allows for convenient and fast positioning of printing based on the reference cross red light projection.

-

The new generation of lightweight sliding sleeves, paired with composite bearing seats, offers fast, stable, and accurate performance.

-

It improves stability, sealing, and precision to achieve optimal performance.

-

-

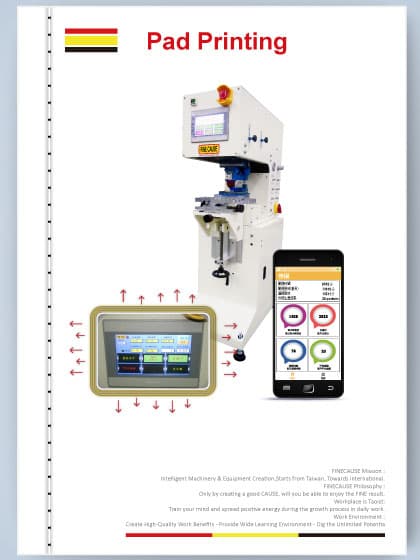

The pad printing machine is equipped with a 7" HMI and a PLC, providing excellent visual effects, easy operation, and more user-friendly.

-

The HMI allows for easy switching of languages, offering options such as Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

The number of prints can be set. The machine will automatically stop and display a prompt when the set number is reached.

-

The PLC (Programmable Logic Controller) is easy to add or modification functions.

-

-

The pad printing machine adopts a pressure-regulating ink scraping system (Patent No. M311585), which allows for easy adjustment of the ink cup scraping pressure.

-

The pad printing machine is equipped with light bulbs for auxiliary illumination.

The advantages of using a Tagless Printing Machine are as follows:

-

High-Quality Printing Effect: The Tagless Printing Machine employs modern printing technology to achieve high-quality printing results on various materials and garments. Whether it's intricate patterns or complex designs, it can present clear and long-lasting effects.

-

Enhanced Durability: The printing inks and techniques used in the Tagless Printing Machine maintain vibrant colors and clear patterns even after multiple washes and wear, increasing the durability and long-term value of the products.

-

Flexibility and Versatility: This type of printing machine can be used on a variety of garments and products, including t-shirts, sportswear, hats, and other items. It can accommodate different shapes and sizes of printing, thus meeting diverse customer demands.

-

Environmental Friendliness and Energy Efficiency: Some Tagless Printing Machines utilize environmentally friendly water-based inks, reducing environmental impact compared to traditional label sewing methods. Additionally, they save energy and resources.

-

Rapid Production Speed: Tagless Printing Machines typically feature high printing speeds, allowing for the efficient printing of large quantities of products within a short period. This aids in boosting production efficiency and delivery times.

-

Precise Positioning and Alignment: The Tagless Printing Machine is equipped with a high-precision positioning and alignment system, ensuring the accurate and error-free printing of patterns onto the designated areas of the product. This reduces printing errors and waste.

-

Cost Reduction: While the initial investment cost of a Tagless Printing Machine might be higher, in the long run, it can lower printing costs and subsequent product replacement expenses. Since there's no need to stock various sizes of fabric labels, the overall cost of printing can be reduced.

-

In summary, the Tagless Printing Machine excels in providing high quality, durability, flexibility, and environmental benefits. It serves as a valuable printing solution for designers, manufacturers, and consumers alike.

Optional customized super useful flip jig.

-

Automatic/Manual switch for easy adaptation to different printing needs.

-

Supports vertical printing and 90-degree rotation printing.

-

Complete double-sided printing in a single operation, saving time and effort for printing different sides of longer objects!

Specifications

| Model | FC-192ASC |

|---|---|

| Printing Colors | 2 |

| Suggested Max. Printing Area (mm) | Ø75 |

| Suitable Cliché Size (mm) | 120X240 |

| Pad Slide Travel Distance | 200 |

| Distance Between 2 Sets of Printing Pad | 200mm |

| Productivity / Hour | 800~1500 pcs |

| Machine Size (cm) | L:75 W:78 H:140 |

| Net Weight | 140 KG |

Videos

-

2-Color Pad Printer with Pad Slide Mechanism (Tagless Label Printing Machine)-FC-192ASC

2-Color Pad Printer with Pad Slide Mechanism (Tagless Label Printing Machine)-FC-192ASC

-

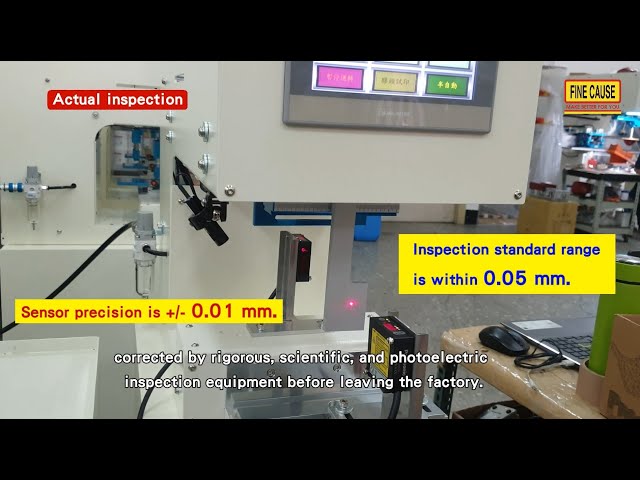

Pad printing machine precision inspection before leaving the factory

Pad printing machine precision inspection before leaving the factory

-

Pad Printing Machine by Temp-control

Pad Printing Machine by Temp-control

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

-

2-Color Ink Cup Pad Printer with Pad Slide Mechanism + Customized Flip Jig - FC-192ASC

2-Color Ink Cup Pad Printer with Pad Slide Mechanism + Customized Flip Jig - FC-192ASC

Downloads

-

FC-192ASC-Two Color Pad Printing Machine with Rubber head Shuttling-DM Download

FC-192ASC-Two Color Pad Printing Machine with Rubber head Shuttling-DM Download

FC-192ASC-Two Color Pad Printing Machine with Rubber head Shuttling-DM Download

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

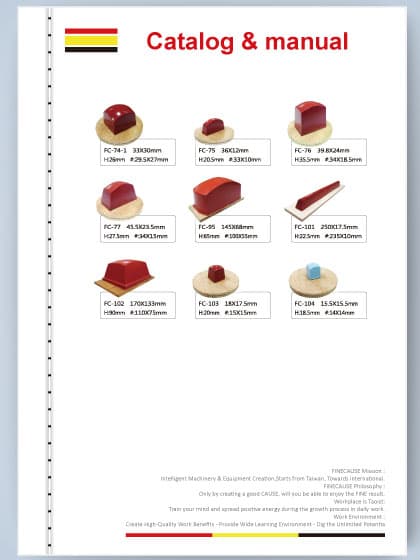

Catalog of Printing Pad

Catalog of Printing Pad

Catalog of Printing Pad

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

Pad printing technology

Pad printing technology

Pad printing technology

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links