Reference

SKD11 Material and Heat Treatment

| Filename | SKD11 Material and Heat Treatment.pdf |

| File Size | 318.0KB |

| Revision Date | 2025/06/25 |

Application of SKD11 Steel and Heat Treatment in Pad Printing Steel Plates

SKD11 Material and Heat Treatment

■ Introduction to SKD11 Material

SKD11 is a high-carbon, high-chromium alloy steel known for its exceptional hardness and suitable toughness, making it widely used in various applications such as stamping dies, plastic molds, and more. As a typical air-hardening steel, SKD11 offers temper hardening and is considered one of the best alloy tool steels for wear resistance. Key features include:

-

Strong Wear Resistance: Due to its composition, which includes elements like molybdenum and vanadium, SKD11 material exhibits excellent wear resistance, capable of withstanding prolonged wear and impact.

-

Excellent Hardenability: SKD11 undergoes minimal deformation during quenching, with a post-quenching hardness of HRC58-62, providing superior wear resistance and long service life.

-

High Hardness and Toughness: The quenched SKD11 material offers extremely high hardness and suitable toughness, with the hardness reaching HRC58-62 after proper tempering. Residual austenite can be eliminated through cryogenic treatment or high-temperature tempering, further stabilizing its structure.

-

Versatility: SKD11 is commonly used in large-scale production molds, including stamping dies, plastic molds, and pad printing steel plates. Its outstanding wear resistance and non-deforming characteristics make it a preferred material in mold manufacturing.

■ Application of SKD11 in Pad Printing Steel Plates

-

Material and Hardness: Pad printing cliche plates often use SKD11 material, which, after heat treatment, achieves an SKD11 hardness of HRC60-62. This ensures both engraving precision and durability.

-

Engraving Precision: SKD11 steel plates for pad printing can achieve a minimum dot diameter of 0.03mm, with a minimum spacing of 0.03mm. The engraving depth remains stable, with no issues of graphic enlargement or deformation, ensuring high-quality printing results. SKD11 steel plates are suitable for both ink tray and ink cup pad printing machines!

-

Reusability: SKD11 pad printing steel plates can be reused. When the design on an old plate is corroded or no longer in production, FINE CAUSE uses the FC-Steel-1 Lapping/Polishing Machine , FC-Steel-2 Lapping Polishing Machine(Small-Scale ) or FC-Steel-3 Automatic Lapping and polishing machine for surface grinding, allowing new patterns to be reapplied on the same steel plate—effectively extending its lifespan and reducing production costs.

How to Choose a Lapping and Polishing Machine? Should You Go with Dry Lapping or Wet Lapping?

▲ FC-Steel-1 Lapping/Polishing Machine for

supporting workpieces up to 400×600 mm in size.

▲ FC-Steel-3 Automatic Lapping and polishing machine/Lapping equipment (medium size)

- SKD11 pad printing steel plates are applicable to both ink cup pad printing machines and ink tray pad printing machines!

■ Heat Treatment Process of SKD11

Vacuum Heat Treatment: SKD11 material typically undergoes vacuum heat treatment, with quenching temperatures exceeding 1000°C and commonly using low-temperature tempering (150-200°C). The hardness can reach HRC61 or above. Vacuum heat treatment effectively reduces the formation of oxide layers, enhancing the surface finish and performance of the steel.

Secondary Tempering: Secondary tempering can be selected as needed to maintain or reduce hardness. This process reduces residual austenite, stabilizing the steel's structure and improving toughness. This is particularly important for molds that require a balance between hardness and toughness.

Annealing: After annealing, the SKD11 hardness returns to its pre-heat treatment level of HRC15-20, which is typically used when there has been a processing error or the material needs to be reworked. Annealing allows the rearrangement of the steel's crystal structure, reducing hardness and making it easier for subsequent machining.

■ Terminology Explanation

Quenching: Quenching involves heating ferrous metals above the transformation point (above 723°C) and then rapidly cooling them, refining the grain structure and increasing hardness. Quenched steel is hard but brittle, so tempering is usually needed to prevent brittleness.

Tempering: Tempering refers to reheating quenched steel to a temperature below the austenitic transformation point, then cooling it. This process converts residual austenite into martensitic structure, reducing brittleness and improving toughness. Tempering also relieves stresses induced by quenching and can adjust hardness and toughness based on the tempering temperature.

Annealing: Annealing involves heating ferrous metals above the transformation point, then slowly cooling them in a furnace. This process reduces hardness, coarsens the crystalline grains, and makes the metal easier to process. It's typically used when reprocessing is needed or when errors occur during processing.

■ Purpose and Methods of Tempering

Adjusting Hardness: The primary purpose of tempering is to adjust the hardness of quenched steel, preventing the over-hard steel from becoming brittle during use.

Stress Relief: Tempering effectively relieves internal stresses induced by quenching, preventing material failure due to stress concentration.

Improving Toughness: Proper tempering can significantly improve the toughness of steel, making it more durable during use.

Secondary Hardening: In some alloy steels like SKD11, carbides precipitate during tempering, causing secondary hardening, which further enhances the steel's hardness and wear resistance.

■ Selection of Heat Treatment

Depending on the application, SKD11's heat treatment can be chosen for low tance or high-temperature tempering to improve toughness. Vacuum heat treatment is commonly used, as it effectively reduces oxide layers and enhances material performance.

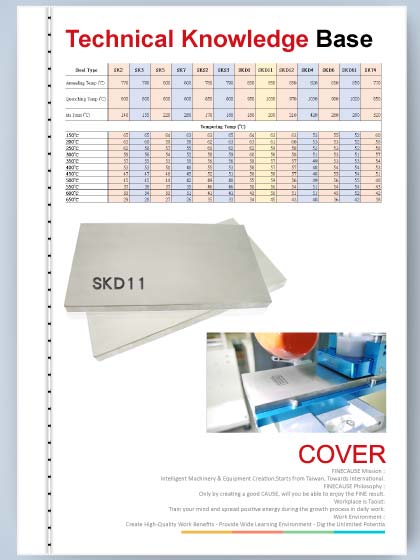

■ Heat Treatment Temperature and Hardness Comparison Chart for Steel Types

| Steel Type | SK2 | SK3 | SK5 | SK7 | SKS2 | SKS3 | SKD1 | SKD11 | SKD12 | SKD4 | SKD6 | SKD61 | SKT4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Annealing Temp (°C) |

770 | 790 | 800 | 800 | 780 | 790 | 850 | 850 | 850 | 820 | 850 | 850 | 770 |

| Quenching Temp (°C) |

800 | 800 | 800 | 800 | 850 | 800 | 950 | 1030 | 970 | 1030 | 980 | 1020 | 850 |

| Ms Point (°C) |

140 | 155 | 220 | 280 | 170 | 180 | 180 | 200 | 210 | 420 | 280 | 280 | 320 |

| Tempering Temp (°C) | |||||||||||||

| 150°C | 65 | 65 | 64 | 63 | 63 | 65 | 64 | 63 | 63 | 53 | 55 | 52 | 60 |

| 200°C | 63 | 60 | 59 | 58 | 62 | 63 | 63 | 61 | 60 | 53 | 53 | 52 | 58 |

| 250°C | 62 | 58 | 57 | 55 | 60 | 62 | 62 | 59 | 58 | 53 | 53 | 52 | 58 |

| 300°C | 59 | 56 | 54 | 52 | 58 | 59 | 60 | 58 | 58 | 51 | 53 | 51 | 57 |

| 350°C | 57 | 55 | 53 | 50 | 56 | 56 | 58 | 57 | 57 | 49 | 53 | 53 | 54 |

| 400°C | 53 | 53 | 51 | 48 | 55 | 53 | 58 | 57 | 57 | 48 | 54 | 54 | 53 |

| 450°C | 47 | 47 | 46 | 45 | 52 | 51 | 56 | 58 | 57 | 48 | 55 | 54 | 51 |

| 500°C | 45 | 45 | 44 | 42 | 49 | 48 | 55 | 59 | 56 | 49 | 56 | 55 | 48 |

| 550°C | 37 | 38 | 37 | 35 | 46 | 46 | 50 | 56 | 54 | 51 | 54 | 54 | 43 |

| 600°C | 33 | 34 | 33 | 31 | 41 | 41 | 43 | 50 | 51 | 51 | 45 | 52 | 42 |

| 650°C | 29 | 28 | 27 | 26 | 35 | 33 | 34 | 45 | 43 | 48 | 36 | 42 | 38 |

For the detailed information, please download the file by clicking the Download button.

Links

Links