Products

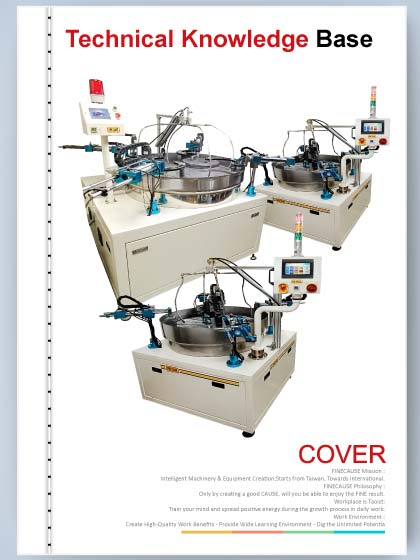

Lapping Machine/Lapping Polishing Machine

Lapping Machine/Lapping Polishing Machine

Product Info

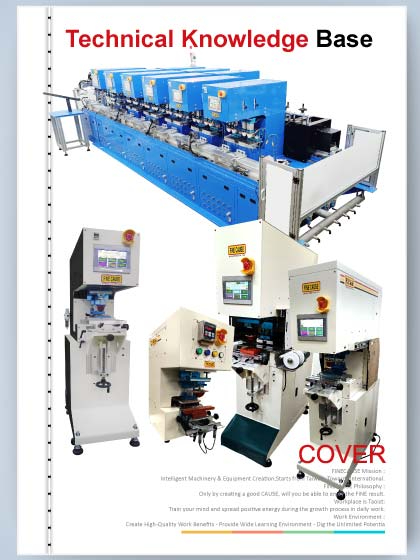

FC-Steel-Lapping Machine/Lapping Polishing Machine

Lapping Machine/Lapping Polishing Machine (Large Size)

High-precision grinding, specifically designed for multi-material workpieces.

Suitable for a wide range of metal and non-metal workpieces, such as SKD11 steel plates, ceramic components, crystal materials, and mobile phone parts. Precision grinding and mirror polishing are achieved with exceptional flatness and parallelism.

Key Features (Wet Grinding and Polishing Equipment)

-

Wet grinder design: Utilizes a recirculating slurry flow system to prevent high-temperature deformation and ensure stable grinding performance.

-

Worktable diameter up to 1100mm: Capable of handling workpieces up to 400×600 mm (size may vary depending on the workstations adjustment).

-

Four workstations: capable of processing single, double, or four workpieces simultaneously.

Multi-stage motion mode settings:

-

Workstations can be set to operate simultaneously, sequentially, or independently.

-

Customizable forward and backward dwell time and number of times.

-

Adjustable rotation speed of the grinding worktable.

Intelligent Control: HMI Display Interface

-

Upgraded 7" human-machine interface (HMI)

-

Displays equipment operating status and various parameter settings (e.g., worktable rotation speed, grinding time, workstation parameters)

-

Manual individual testing available for each actuator and drive unit.

-

Indicator lights show the status of each sensor.

-

Features timer settings and timeout alarms to enhance operational efficiency and safety.

-

Color TFT touchscreen with selectable built-in languages: Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

How to Choose a Lapping and Polishing Machine? Should You Go with Dry Lapping or Wet Lapping?

Proprietary Technologies:

-

Pneumatic cylinders automatically move the workstations to reduce wear.

-

Removable grinding pads for easy maintenance and quick replacement.

-

Multiple grinding block design to improve grinding uniformity.

-

Four displacement mechanisms to prevent localized worktable wear.

✅ This machine is ideal for applications involving wet grinders and automatic grinding and polishing machines, making it the best choice for advanced manufacturing processes.

Grinding Results Display:

-

Surface roughness reports can be provided, indicating the type of abrasive used.

-

Multi-stage polishing quality can be achieved through different abrasive grit sizes and optional polishing pads.

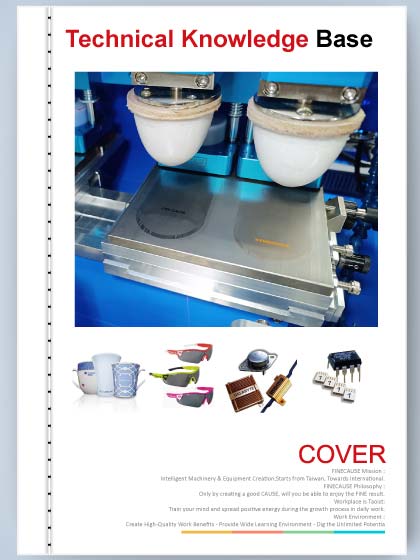

Typical Application Materials and Workpieces

Applicable Grinding Materials:

Cast iron, aluminum, copper, gold, silver, platinum, high carbon steel, alloy steel, glass, rubber, plastics, marble, granite, silicon, quartz ceramics, nylon, carbon, and more.

Common Grinding Workpieces:

SKD11 pad printing steel plates (heat-treated), tungsten carbide parts, ceramic components, valve plates, oscillators, ferrite cores, sewing machine parts,wafers, watch glass, sapphire, water stop valves, aluminum plates, gaskets, valve discs, oil seals, clutch plates, concentric rings, smartphone panels, compressor/vacuum pump/refrigeration valves, and others.

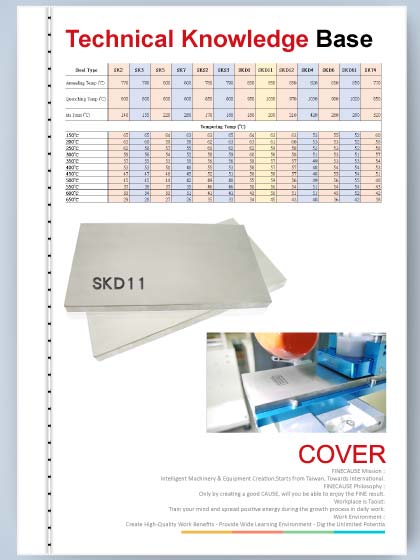

Three-Stage Precision Grinding Process (Example: SKD11 Pad Printing Steel Plate)

1. Rough Grinding: Performed using a surface grinder with grinding wheels.

2. Fine Grinding: Conducted with a wet-type surface grinder using abrasive media.

3. Mirror Polishing: Final surface treatment carried out with a wet grinding and polishing machine.

👁️ In most general applications, the process stops at the second stage. However, industries with higher surface requirements—such as contact lens manufacturing—require the third stage of mirror polishing.

Learn more about FineCause abrasive grinding for pad printing plates — click here.

Advantages of the FineCause Wet Grinding and Lapping Machine

-

Independently developed with multiple patented technologies

-

Cooperate with government CITD R&D programs

-

Stable, durable, and easy to maintain

-

Ideal for pad printing steel plates and precision contract grinding and polishing

👉 [Related Article] What Are Wet Grinding Materials? Learn the Key to High-Efficiency Polishing

Specifications

| Model | FC-Steel-1 Lapping Machine |

|---|---|

| Power Supply | 3-phase 220V |

| Number of Workstations | 4 sets |

| Maximum Workpiece Size | Single piece up to 400 × 600 mm |

| Machine Dimensions | L:178 W:163 H:152 cm |

| Net Weight | 1500 kg |

Videos

-

FC Thin Cliche Plate

FC Thin Cliche Plate

-

Laser Engraving Cliche Plate (thick)

Laser Engraving Cliche Plate (thick)

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Magnetic Toolbox-(Magnetic Containers)

Magnetic Toolbox-(Magnetic Containers)

-

Pad printer Clean Ink Cup tutorial

Pad printer Clean Ink Cup tutorial

Downloads

-

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

How to Choose a Wet Lapping Machine/Lapping Polishing Machine?

-

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

SKD11 Material and Heat Treatment

-

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

The Relationship Between Pad Printing Plate Etching Depth and Printing

-

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links