Reference

Pad Printer Technology: Thermostatic Pad Printing Machine Meets the Automatic Solvent Adding System

| Filename | Pad-Printer-Printing-Machine-Technology.pdf |

| File Size | 372.2KB |

| Revision Date | 2025/11/11 |

Pad Printing Machine Technology : Stable and Efficient Printing with Thermostatic Control and Automatic Solvent Adding System

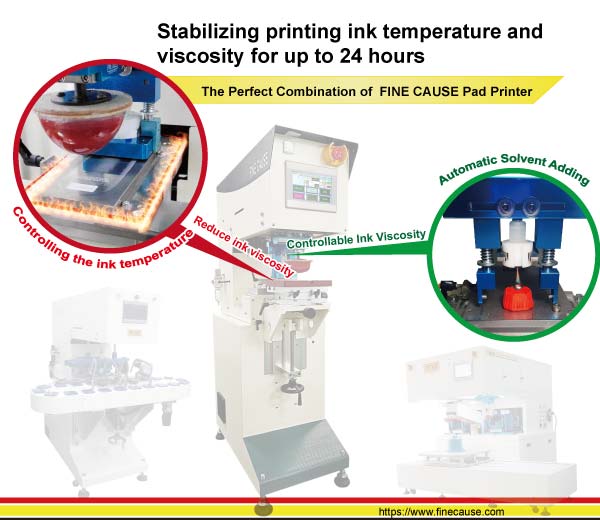

Stabilizing printing ink temperature and viscosity for up to 24 hours, automatically adding solvent based on the number of prints.

Encountering Ink Problems During Long-Term Printing?

Do you frequently encounter unstable print quality, color variations, or incomplete ink transfer during the pad printing process?

Common Issues Include:

• The ink thickens due to the sloshing of the ink cup, requiring continuous manual adjustment.

• Edge blurring or stringing (burrs) occurs after long periods of operation.

• Solvent evaporation leads to pattern shrinkage or missing details.

• Uneven color density due to incomplete ink transfer.

If these problems look familiar, then FineCause’s combination of the Thermostatic Pad Printing System and Automatic Solvent Adding System is your ultimate solution for maintaining printing stability, efficiency, and quality consistency.

--------------------------------------------------------------------------------

Step 1: Mastering Ink Temperature to Enhance Transfer Stability — Thermostatic Printing System for Pad Printers

Fear no long-term mass production; suitable for single-color to multi-color printing.

No more fear of poor ink release during long pad printing runs!

FineCause's brand-new patented [Pad Printing Machine with Controllable Ink Temperature] is officially launched.

All FineCause pad printers can be upgraded with the Thermostatic Printing System to become a Thermostatic Pad Printer. This technology represents a new milestone in the field of pad printing, with its core being temperature control to maintain optimal ink performance.

Why is Ink Temperature Important?

Scientific experiments prove that the higher the ink temperature, the lower its viscosity, the higher its fluidity, and the faster the solvent volatilization speed.

By controlling and stabilizing the ink temperature (for example, maintaining it at 40°C, regardless of environmental conditions), multiple benefits can be achieved:

1.Eliminates Stringing/Burrs: Higher temperature reduces ink viscosity and increases fluidity, thereby effectively preventing stringing. Faster solvent evaporation during transfer ensures complete ink release. Because the ink detaches quickly and the transfer is clean, it may no longer be necessary to rely on anti-stringing agents (ST1).

2. Increases Ink Transfer Rate and Opacity/Covering Power: The improved ability of the ink to absorb and release results in a thicker and more uniform ink layer. This achieves complete ink deposit with every print. Excellent opacity and covering power can be achieved even with deep etching (up to 0.035 mm, compared to the common depth of 0.025 mm).

3. Stabilizes Production Conditions: Whether the working environment temperature is 10°C or 30°C, the pad printing machine thermostatic system ensures constant ink temperature during printing, thereby reducing a major production variable and maintaining stable print quality.

This technology has obtained a patent in Taiwan (Invention Patent No.: I 762245).

FineCause offers this upgrade service for all standard pad printing machines and customized pad printers (including single-color and multi-color models).

--------------------------------------------------------------------------------

Step 2: Maintaining Ink Concentration Consistency — Automatic Solvent Adding System for Pad Printers

Temperature stabilizes solvent evaporation, and automatic solvent replenishment maintains ink concentration. This dual stability ensures the ink state is consistent "From the First Print to the Last Print."

Ink viscosity changes during long-term printing. As the solvent evaporates (especially during the ink cup movement/molecular collision), this leads to:

• Image size reduction

• Color deviation

• Poor ink transfer

• More frequent cleaning and downtime

FineCause developed the "Pad Printer with Controllable Ink Viscosity," equipped with the Automatic Solvent Adding System (Model 6K001), which won Invention Patent No. I889206.

This system uses the number of ink cup movements as the control basis. Combined with Human-Machine Interface (HMI) settings, it automatically replenishes solvent and stabilizes ink concentration, eliminating the need for manual adjustments or stopping the machine.

System Features:

✅Production uninterrupted: Solvent is automatically replenished during printing, eliminating the need to stop for ink adjustment.

✅Precise control of addition amount: Based on the number of prints set, solvent is added in multiple micro-doses.

✅Maintains ink stability: Prevents issues like thickening, drying, and uneven color.

✅Supports various inks and materials: HMI settings allow flexible adjustment of addition interval and dosage.

✅Compatible with new and old machines: Older pad printers can be retrofitted back at the factory, eliminating the need for repurchase.

--------------------------------------------------------------------------------

Perfect Combination: Thermostatic × Automatic Solvent Adding System — Pad Printing Enters a New Era of Smart Automation

When the Thermostatic Printing System stabilizes ink activity, and the Automatic Solvent Adding System maintains concentration balance, these two technologies together create an environment for long-term stable, high-precision pad printing production.

✅ No longer affected by temperature, time, ink volatilization, or other factors.

✅ Print quality remains consistently stable during long, continuous production runs.

✅ Improves yield rate and reduces frequency of cleaning and adjustment.

✅ Allows pad printing to formally enter the new era of "Smart Control × High Efficiency."

Summary

Whether you are a manufacturer pursuing high-precision printing or an operator hoping to enhance production line stability, the FineCause manufactured Thermostatic Pad Printing System and Automatic Solvent Adding Technology will be your essential partner in moving toward smart manufacturing and quality upgrade.

We constantly research and improve, providing products beyond your imagination.

Frequently Asked Questions (FAQ)

Q1: Why does a pad printer need a thermostatic printing system?

A1: The thermostatic system stabilizes ink temperature to prevent viscosity changes caused by ambient temperature fluctuations. With consistent temperature, ink transfer becomes more stable, coverage improves, and issues like stringing or poor transfer are greatly reduced.

Q2: If the pad printer has a thermostatic system, is the automatic solvent adding system still necessary?

A2: Yes. The thermostatic system controls temperature, but solvent evaporation over time still thickens the ink. The automatic solvent adding system precisely replenishes the evaporated solvent to maintain ink concentration. Combining both ensures consistent ink performance and print quality during long production runs.

Q3: How does the automatic solvent adding system work?

A3: The system uses the pad printer’s cup movement count as the control basis. It automatically adds small, measured amounts of solvent at set intervals, closely matching real evaporation behavior to keep ink concentration stable 24/7.

Q4: Can these systems be added to existing pad printers?

A4: Yes. Both the thermostatic printing system and the automatic solvent adding system can be retrofitted to FINECAUSE’s older pad printing machines, allowing easy upgrades without purchasing new equipment—extending machine lifespan and improving productivity.

Q5: How do these systems improve printing quality?

A5: By maintaining stable ink temperature and concentration, they ensure consistent color, sharper details, and complete ink transfer. During long production runs, they significantly reduce defects, improving both yield and machine uptime.

Q6: What types of printing or products can benefit from these systems?

A6: They are suitable for single-color, multi-color, and special material printing applications—especially where color consistency, fine detail, and long-term stability are critical.

👉Learn more technical information:

• Pad Printer Thermostatic Printing System with Controllable Ink Temperature

Links

Links