Products

Pad Printing Machine Automatic Solvent Adding System

Pad Printing Machine Automatic Solvent Adding System

Product Info

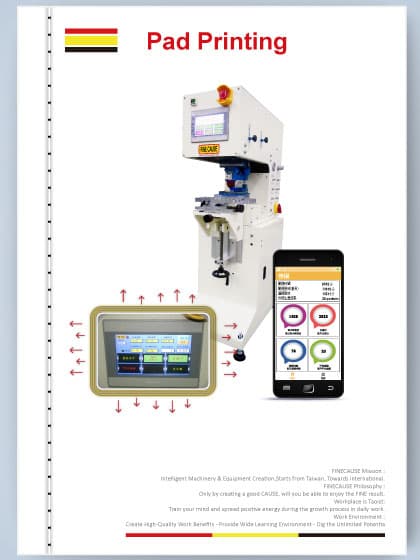

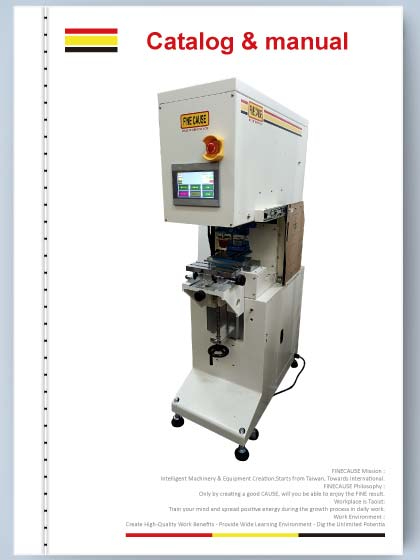

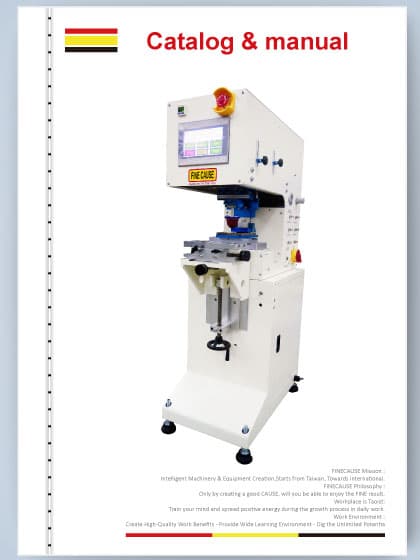

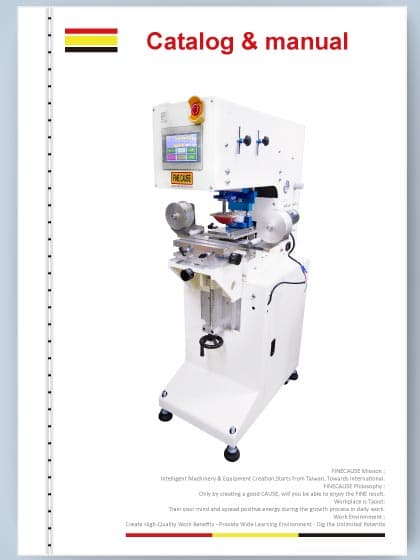

▲ Pad Printing Machine with Controllable Ink Viscosity-Automatic Solvent Addition

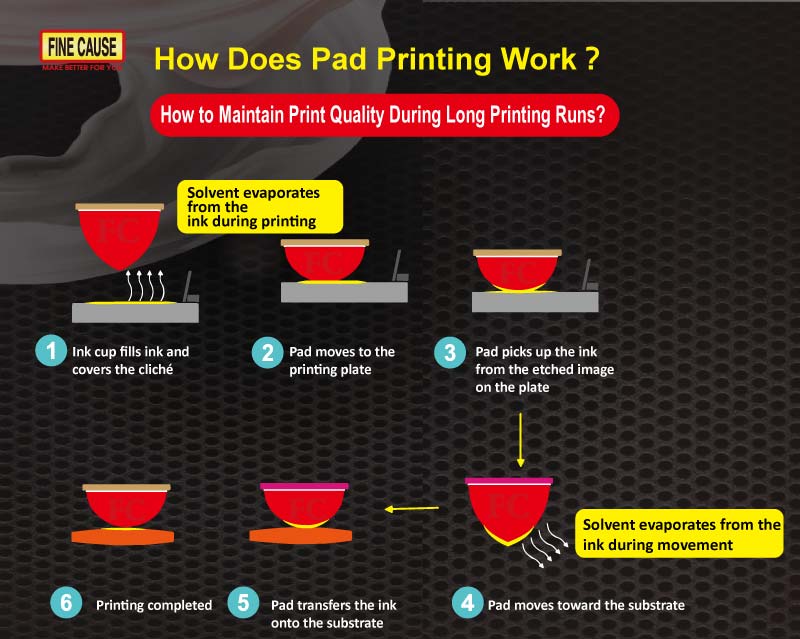

How Does Pad Printing Work?

How to Maintain Print Quality During Long Printing Runs?

In fact, the evaporation of ink inside the ink cup is mainly caused by agitation due to the reciprocating motion (molecular collision), while the influence of time alone is relatively minor. By using the number of ink cup movements as the basis for solvent addition, this represents a modern and advanced pad printing technology!"

***Achieve Quality Through Scientific Control***

Pad Printing Machine with Controllable Ink Viscosity –Pad Printing Machine Automatic Solvent Adding System

Smart Production ・ Ink Stability ・ Quality Enhancement

✅ Automatic Solvent Adding Mechanism | ✅ Taiwan Invention Patent: Patent No. I889206 | ✅ Available for New Machines or Retrofit of Existing Machines

Why use an automatic solvent adding mechanism?

-

During the pad printing process, the ink gradually thickens due to solvent evaporation over time, causing color deviations, poor printing quality, and increased cleaning frequency.

-

In the pad printing process, ink cup’s movement and sloshing make the ink evaporate and thicken, resulting in smaller image sizes, poor printing performance, and more frequent issues such as ink stringing and breakage.

-

Manual solvent addition requires stopping the machine, which is time-consuming and inaccurate, ultimately affecting product quality and production efficiency in the long run!

【FineCause New Invention】Smart Solvent Adding System

Our newly developed automatic solvent adding mechanism is installed above the ink cup and allows precise control of the timing and amount of solvent added through the HMI. This system keeps the ink at optimal viscosity during production without the need to stop the machine!

Features:

-

Adds solvent in small amounts multiple times to maintain stable ink viscosity for up to 24 hours.

-

Automatically adds solvent based on the number of prints to prevent thickened or dried ink.

-

No need to stop the machine for automatic solvent addition.

-

Does not affect production line continuity, boosting uptime and yield rate.

-

Compatible with a variety of inks and materials

-

Droplet frequency and volume can be fine-tuned as needed—high flexibility.

Works with both new and existing machines

Older models can be retrofitted to extend machine life and enhance functionality.

▲ Officially granted Invention Patent No. I889206

🎯 Perfect for:

Manufacturers aiming to improve print quality and production automation

Production lines that require high consistency and minimal downtime

Products demanding high color stability

Long, continuous printing runs that cannot afford interruptions

📌 Made in Taiwan × Patented Technology × Smart Upgrade

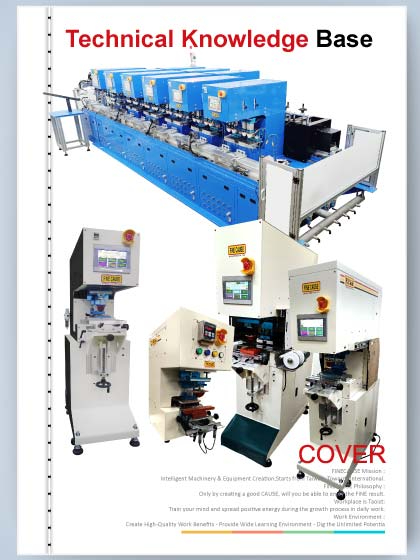

Fine Cause focuses on intelligent upgrades for pad printing machines, continuously driving automation and quality stability.

This patented system is a key step toward smart manufacturing.

Click the link to view FineCause's various pad printers, all of which can be equipped with an automatic solvent addition system.....

Specifications

| HMI (Human-Machine Interface) Settings Description: | |

|---|---|

| Setting Item | Description |

| Solvent Adding Interval Count | Set how many prints to complete before triggering one solvent addition cycle. |

| Solvent Adding Times | Number of up-and-down strokes per addition (1 time = one up + one down). |

| Adding Delay Time | Delay between up and down strokes during each addition to prevent splashing or overfeeding. |

Videos

-

Pad Printing Machine with Controllable Ink Viscosity

Pad Printing Machine with Controllable Ink Viscosity

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Pad Printing Machine by Temp-control

Pad Printing Machine by Temp-control

-

FC-191ANC-CI-Pad printer w /Cross Red light Laser Pointer moudle and InkCup Cylinder independently

FC-191ANC-CI-Pad printer w /Cross Red light Laser Pointer moudle and InkCup Cylinder independently

-

Pad printing machine/Pad printer Production Data APP

Pad printing machine/Pad printer Production Data APP

Downloads

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

-

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

Electric Servo Single Color Pad Printing Machine-FC-161ANS DM

-

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

FC-161ANC Single-Color Ink Cup Pad printing machine/Pad Printer DM

-

FC-161ENC-semi automatic pad printing machine(Running Steel Plate Single-Color Ink Cup)

FC-161ENC-semi automatic pad printing machine(Running Steel Plate Single-Color Ink Cup)

FC-161ENC-semi automatic pad printing machine(Running Steel Plate Single-Color Ink Cup)

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links