Products

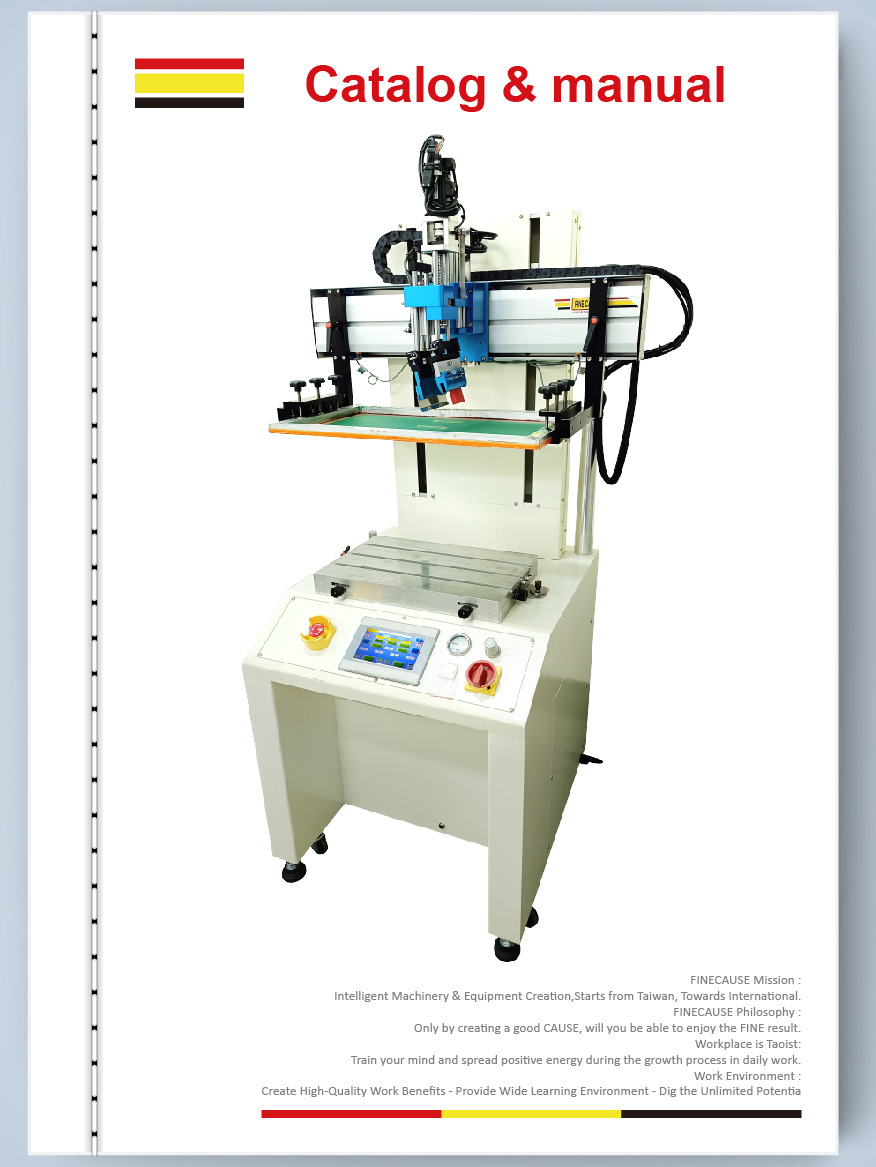

Screen Printing Machine with 3-Axis Servo Motor

Screen Printing Machine with 3-Axis Servo Motor

Product Info

FA-400TQN-Screen Printing Machine with 3-Axis Servo Motor (Left and Right, Up and Down, Squeegee Servo)

■ 3-Axis Servo Motor (Left and Right, Up and Down, Squeegee Servo)

1st axis~ Left and right servo

-

Left and right servo adjustment - Ink scraping is precisely driven by servo motor.

-

Ink scraping adopts servo motor with linear guideways and ball screw mechanisms, ensuring precise control throughout the entire ink scraping process.

-

2nd axis~ Up and down servo

-

Up and down servo adjustment - The up and down of screen stencil is precisely driven by servo motor.

-

The up and down movement of the screen stencil is controlled by servo motors, ensuring fast, stable, and quiet operation.

-

3rd axis~ Squeegee servo

-

Squeegee servo adjustment - The squeegee position can also be digitally and precisely adjusted.

-

Servo motors for precise linear movement of the squeegee. HMI allows easy adjustment of the squeegee up-and-down position, enabling effortless and precise settings.

- 7.0" color touch screen, built-in 5 languages, English, Indonesian, Vietnamese, Thai, and Traditional Chinese.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

The abnormal alarm marquee display facilitates quick troubleshooting for production line personnel.

-

With electronic air pressure sensing, the machine will alarm automatically for insufficient air pressure.

-

The usage times of squeegee and screen stencil can be set; when the set value is reached, the machine will automatically stop and alarm.

-

Adopt PLC for easily adding and modifying functions:

-

The servo operating position is displayed on the screen.

-

Multiple sets of formulas can be stored. Parameters can be set.

-

-

Magnetic squeegee clip (Patent No. M390871)

-

The squeegee position can be slided easily and the squeegee can be adjusted and disassemble quickly.

-

- Production history function: built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown.

-

With smart factory Industrial Internet of Things (I.O.T.), wherever you are, you can view the productivity report by downloading the FineCause APP.

Specifications

| Model / Specification | FA-400TQN |

|---|---|

| Printing Color | 1 |

| Productivity / Hour | 600~1800 pcs/hr |

| Machine Size | L:70 W:90 H:163 cm |

| Air Pressure (kg/cm2 psi) | 4~6 |

| Power Consumption (a) | 10A |

| Voltage (v) | Single Phase 220V |

| Platform Size (mm) | 320*500 |

| Max. Printing Area (mm) | 320*300 |

| Allowable Object Height (mm) | 200 |

| Left and Right Stroke (mm) | 400 |

| Screen Stencil Lifting Height (mm) | 0~400 |

| Max. Screen Stencil Size (cm) | 50*72 |

| Screen Stencil Front and Back Fine Tune Distance (mm) | ±25 |

| Platform Left and Right Fine Tune Distance (mm) | ±8 |

| Platform Left and Right Tilt Angle | 10°/50 |

| Lifting Distance of Independent Scraper Set (mm) | |

| Machine Weight | 250 kg |

Videos

-

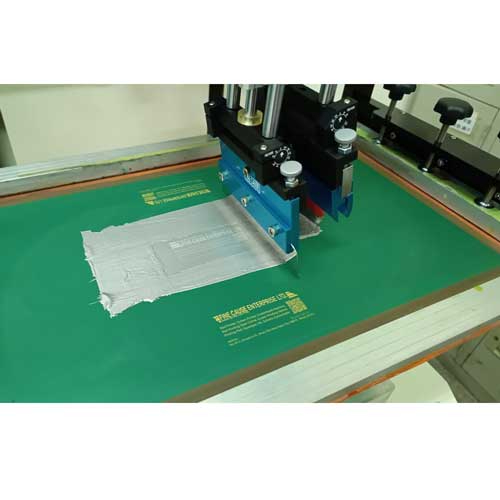

Screen Printing Machine with 3-Axis Servo Motor-FA-400TQN

Screen Printing Machine with 3-Axis Servo Motor-FA-400TQN

-

Screen Printing Knowledge-Part-1 Screen Stencil

Screen Printing Knowledge-Part-1 Screen Stencil

-

Screen Printing Knowledge-Part-2 Squeegee

Screen Printing Knowledge-Part-2 Squeegee

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

-

Screen printing machines Fully Upgraded - Price remains unchanged

Screen printing machines Fully Upgraded - Price remains unchanged

-

Screen Printing Machine/Screen Printer Production Data APP

Screen Printing Machine/Screen Printer Production Data APP

Downloads

-

FA-400TQN-Screen Printing Machine with 3-Axis Servo Motor

FA-400TQN-Screen Printing Machine with 3-Axis Servo Motor

FA-400TQN-Screen Printing Machine with 3-Axis Servo Motor

-

Unitex Squeegees

Unitex Squeegees

Unitex Squeegees

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

Part-1 Screen Stencil-Screen Printing Knowledge

-

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

Part-2 Screen printing machine Squeegee-Screen Printing Knowledge

-

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

Screen Printing Knowledge-Part 3 Screen Printing Ink

-

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

Screen Printing Knowledge-Part 4 Screen Printer

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links