Products

RUCO series 920UV SCREEN PRINTING INK

RUCO series 920UV SCREEN PRINTING INK

Product Info

RUCO series 920UV SCREEN PRINTING INK

The inks of the series 920UV are not detected contents of volatile organic solvents, on the other hand, this series of inks is friendlier to the environment and human bodies. The solid content is 100%, and there is no problem of inconsistency in the thickness of the printing ink film caused by the evaporation of the solvent. UV ink does not clog the screen, so it is suitable for screen printing and printing on delicate products.

-

The solvent of the inks does not damage the printed object. The UV inks perform the stable quality that they have good gloss level of dried ink film, high abrasion resistance, water, oil and solvent resistance, etc

-

The series of 920UV inks perform a short period of drying time that help build a fast printing production line and improve the printing efficiency remarkably

-

The UV inks save the amount of the applied ink in each printing project. The solvent-based inks can print appoximately 50 ㎡ per thousand units, while the UV inks can print about 70 ㎡ under the same conditions

-

Compared with traditional inks, UV inks are stable in physical properties, non-flammable, non-explosive, non-corrosive and volatile, slightly odorous, and can be transported as ordinary goods

Application Fields

-

Universal UV screen printing ink in a thixotropic formulation for the printing on blow moulded objects within the packaging industry. Suitable for pretreated substrates made of polyethylene (PE), polypropylene (PP), PVC and other plastic types as well as for printing on paper and cardboard

-

Substrates may differ in their chemical structure or method of manufacture. A test for suitability must always be carried out before printing

-

Antistatic, mould release agents and slip additives may have negative effects on adhesion, and should be detected and removed prior to printing

Characteristics

-

This high gloss UV ink series is very reactive in nature, assuring good curing and adhesion even when printing at high machine speeds

-

This ink series is not suitable for printing onto food packaging. This high gloss UV ink series is very reactive in nature, assuring good curing and adhesion even when printing at high machine speeds. The inks of the 920UV series are constitutionally free from toxic elements and solvents. However, a test for suitability must always be carried out before printing

-

The inks of this series will exhibit good solvent and water resistance after 12 hours. Due to their viscosity adjustment, which is higher compared to the 985UV series, this UV ink series is also suitable for application under extreme climatic conditions (temperature > 28°C)

Processing Instructions

-

RUCO series 920UV inks are suitable for the overall screen printing industries. The printing speed goes for 800-1600 pcs per hour

-

Pre-treatment of polyolefins (PE/PP) must be performed by Flame Treatment or CORONA-discharge in order to insure the adhesion of the UV screen printing ink to the substrate

-

In case of PE, surface tension needs to be at least 42 mN/m (Dynes/cm), in case of PP at least 52 mN/m (Dynes/cm)

Curing Conditions

-

The varying UV absorption of the individual colours results in a range of curing properties depending on colour and opacity. All colours of the 920UV series can be cured by the use of medium pressure mercury vapour lamps (at least 160 W/cm). The optimum energy output is 250 - 300 Millijoule/cm2. UV curing is followed by a 12 hour post-cure phase after which the ink film is fully cured and has its final properties

-

However, it must be noted, that low radiation intensity, excessive machine speeds or excessive film thickness can have a negative influence on the curing properties and adhesion.

-

Uncured prints are considered a hazardous waste. Therefore, it is recommended to cure misprints under the UV lamp as a matter of principle. After curing, spoilage can be disposed by conventional methods and may be incinerated without causing any difficulties

RUCO series 920UV inks are suitable for screen printing UV ink (ultraviolet light curing)

Ink refers to the use of ultraviolet light with different wavelengths and energies to polymerize the monomers in the ink binder into polymers under ultraviolet irradiation, so that the ink can form a film and dry ink. It also has characteristics of good adhesion, wear resistance, corrosion resistance, weather resistance, etc.

The printing conditions are different and there are many combinations of process changes. This description for reference only and may vary from the actual product.

For more details, please sned us a RFQ form. Our specialist will contact you soon.

Specifications

| Item |

RUCO series 920UV SCREEN PRINTING INK |

|---|---|

| Content (kg) | 1kg |

| Package | Can |

Comparison of Curing Methods

| Mercury UV lamp | LED UV lamp | Infrared lamp | |

|---|---|---|---|

| Power Consumption |

High energy- consuming and heating |

High energy- consuming and heating |

Power saving and non-heating |

| Space Requirement |

Large | Large | Small |

| Odor | Stinks (ventilation system required) | Stinks | Odorless |

| Product Life | Serviced every 1000-hours running | 6000hours | 20K hours |

| Exchangeable Light Tube |

Yes | Yes | No light tube |

| Preheating time | 2-10 mins. | 3-5mins. | 0 sec. |

| Light Source | Defocused | Defocused | Focused |

| Relative Weight | Heavy | Heavy | Very light |

| Budget | High | Medium | Most afforadable |

Videos

-

FA-LV1 Automatic Monochrome Curved Screen Printing Machine (Bottle Printing Machine)

FA-LV1 Automatic Monochrome Curved Screen Printing Machine (Bottle Printing Machine)

-

Clean Screen Printing Plate Tutorial

Clean Screen Printing Plate Tutorial

-

How to recognize Nylon screen and Tetoron screen?

How to recognize Nylon screen and Tetoron screen?

-

Magnetic Toolbox-(Magnetic Containers)

Magnetic Toolbox-(Magnetic Containers)

-

Corona Machine For Curved Surfaces

Corona Machine For Curved Surfaces

-

FA-400/500/600TSN Servo Motor Screen Printer - Operation Video

FA-400/500/600TSN Servo Motor Screen Printer - Operation Video

-

Manual Screen Printer - User Instruction

Manual Screen Printer - User Instruction

Downloads

-

RoHS - 920UV

RoHS - 920UV

RoHS - 920UV

-

TDS - 920UV

TDS - 920UV

TDS - 920UV

-

Declaration of RoHS Compliance - series 920UV

Declaration of RoHS Compliance - series 920UV

Declaration of RoHS Compliance - series 920UV

-

MSDS_920UV_EN

MSDS_920UV_EN

MSDS_920UV_EN

-

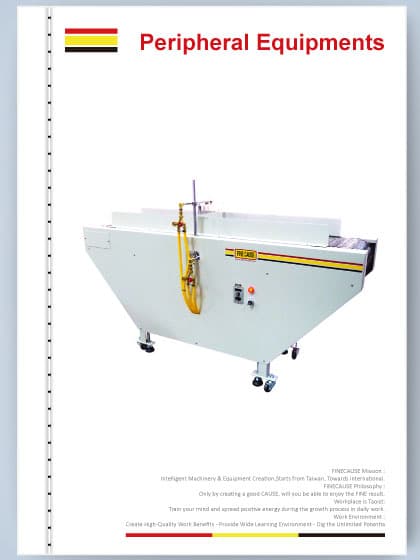

Flame Treatment machine

Flame Treatment machine

Flame Treatment machine

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links