Products

Fully Automatic Cleaning Machine/Automated Cleaning Equipment

Fully Automatic Cleaning Machine/Automated Cleaning Equipment

Product Info

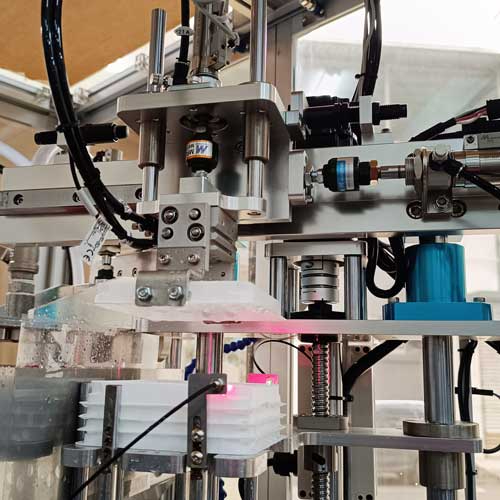

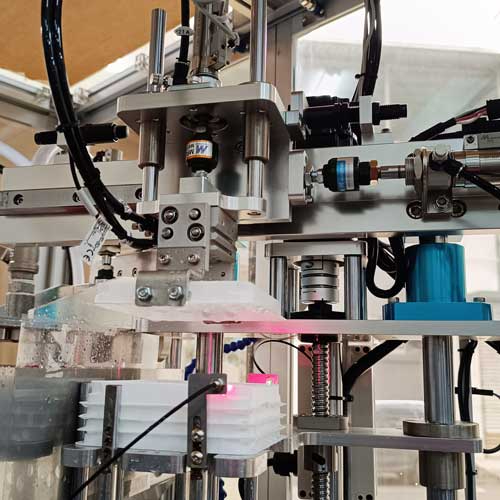

FC-01097-AUTO-FE Fully Automatic Cleaning Machine/Automated Cleaning Equipment

■ Operation Process

Stacked loading → Infeed clamping → 1st RO filtered recirculating wash → 2nd RO filtered recirculating wash → 3rd RO water wash → Blow air to remove water → Outfeed pickup → Stacked unloading

■ Equipment Features

-

Precision 6-station rotary table with inverter control for fast and accurate positioning

-

Water pump with filter and inverter control to ensure clean water quality

-

Dual-stage high and low pressure washing with customizable pressure and sequence

-

Large-capacity RO water tank design:

-

Automatic shut-off when water filling reaches the target.

-

Low-level alarm to ensure pump operation

-

Overflow design to prevent spillage

-

-

Cylinder-driven infeed/outfeed arm mechanisms for high durability and easy maintenance

-

Stacking blanking mechanism ensures precise and stable loading

-

Adjustable spray fixture for wash height and flow, adaptable to various processes

-

Air blow drying module effectively removes surface water to prevent dripping during unloading

-

Servo-controlled outfeed stacking for speed and precision

-

Customizable settings for empty and full positions

-

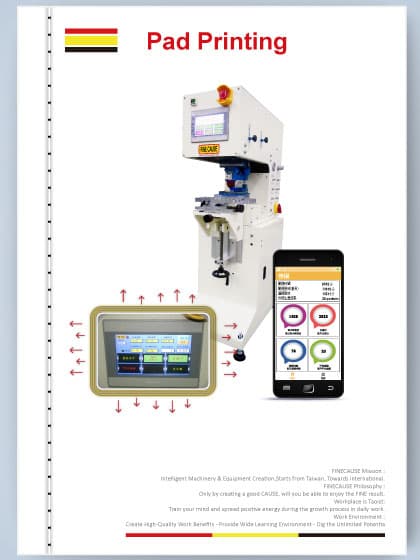

■ Intelligent HMI Control System

-

7-inch color TFT touchscreen with intuitive interface and multilingual support:

-

Traditional Chinese / English / Indonesian / Vietnamese / Thai

-

Clearly labeled sensor positions for easy operation

-

Programmable Logic Controller (PLC) with flexible expandability and functionality

-

Comprehensive alarm system:

-

The human-machine interface displays abnormal alarms, making it easy to quickly troubleshoot.

-

Error log page automatically records abnormal events

-

Electronic air pressure detection with automatic error display

-

-

PLC I/O list provided for easy diagnostics and maintenance

■ Smart Cleaning Management Functions

-

Infeed quantity control: auto batch completion upon reaching preset quantity

-

Outfeed quantity alert: audible notification when count is reached

-

Example: alert when set number carton-ready quantity is reached to improve packing efficiency

-

-

Smart cleaning logic: cleans only when parts are detected, saving resources.

-

Supports storage of 20 cleaning parameter sets, each with customizable names for quick recipe switching.

-

Production history analysis function (built-in bar chart shows last 30 days of data):

-

Hourly output

-

Daily output

-

Operating hours

-

Operation efficiency

-

Average daily production rate

-

This is a custom-designed rotary-type automatic cleaning machine for contact lenses, which can be customized according to material requirements.

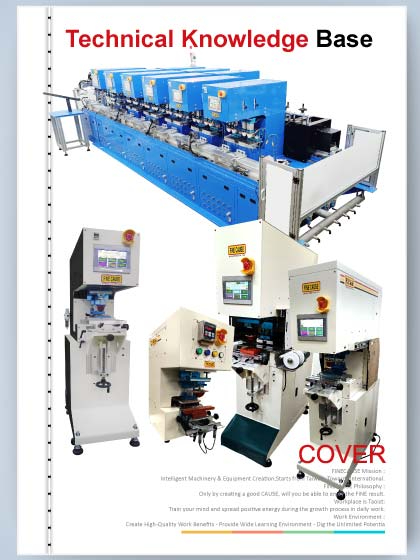

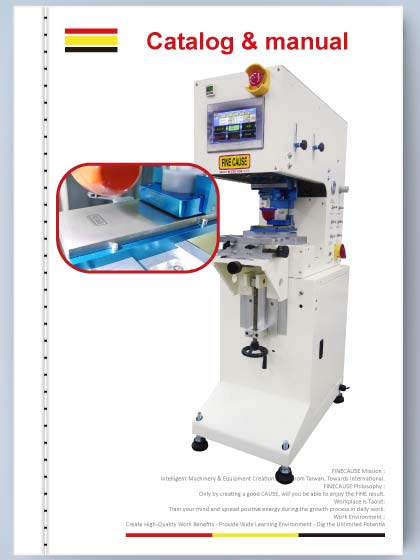

Fine Cause specializes in designing and manufacturing automatic pad printing machines and automatic screen printing machines. With years of expertise in the printing industry, we are committed to providing customers with efficient and highly stable printing solutions.

However, our expertise extends beyond the printing field—we also have rich experience in developing and manufacturing automation equipment and machinery.

We offer end-to-end services, covering automation planning, design, and manufacturing, with integrated system capabilities to create custom automation assembly machines tailored to various industry needs. These include single-axis and multi-axis dedicated machines, multi-station rotary processing machines, and high-efficiency automatic screw fastening machines.

Understanding that every customer's process and production line is unique, Fine Cause provides highly flexible and diversified equipment customization services. From concept design to final machine delivery, our professional team and engineering capabilities help businesses accelerate automation, boost production efficiency, reduce labor costs, and enhance quality consistency.

Choosing Fine Cause means choosing your key partner in automation upgrades.

Fine Cause guides you through "Needs Evaluation," "Performance Comparison," and "Customized Development" to master the core mindset of selecting automation equipment.

📌 Offering diverse automation machinery, design, and upgrade services

Specifications

| Model | FC01097-AUTO-FE |

|---|---|

| Power (V) | 220V |

| Machine Dimensions (cm) | 105*117*156 cm |

| Platform | Six-station rotary disc platform |

| Control Panel | 7.0" color TFT touchscreen |

| RO Filter Cleaning | Stage 1: RO filtered circulating water cleaning |

| Stage 2: RO filtered circulating water cleaning | |

| Stage 3: RO water cleaning | |

| Spray Nozzle Modules | 2 sets |

| Loading Arm | Pneumatic drive |

| Unloading Arm | Pneumatic drive |

| Operation Interface | 7" color touchscreen |

| Net Weight | 450 KG |

Videos

-

Fully Automatic Cleaning Machine / Automated Cleaning Equipment-FC-01097-AUTO-FE

Fully Automatic Cleaning Machine / Automated Cleaning Equipment-FC-01097-AUTO-FE

-

Mixing Machine / Blending Machine - Automatic 720° Gyroscopic Mixer-【GMFC30A-S-TW】

Mixing Machine / Blending Machine - Automatic 720° Gyroscopic Mixer-【GMFC30A-S-TW】

-

Automatic Pad Printing Machine with Multiple Stations/multi-color PadPrinter-36-Color-FC-1636-BRC-FGM

Automatic Pad Printing Machine with Multiple Stations/multi-color PadPrinter-36-Color-FC-1636-BRC-FGM

-

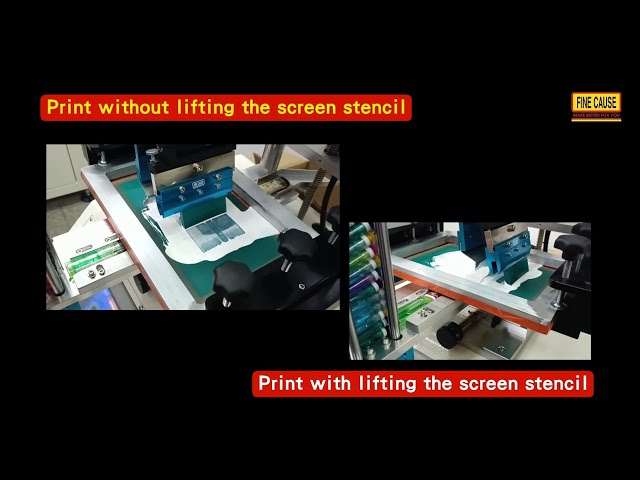

Automatic Flat Screen Printer / Lighter Printing Machine - FA-919

Automatic Flat Screen Printer / Lighter Printing Machine - FA-919

-

Automatic Screen Printer (Printing for Magnetic Stripe Coating)-FA-300TSN-XQ-2

Automatic Screen Printer (Printing for Magnetic Stripe Coating)-FA-300TSN-XQ-2

Downloads

-

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

Automation equipment: evaluation and selection of efficient production lines

-

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

Pad Printer Guide-How to Choose the Right Pad Printing Machine ?

-

Pad Printer Accessories Catalog

Pad Printer Accessories Catalog

Pad Printer Accessories Catalog

-

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

Smart Pad Printer and Screen Printer APP Connection Setting Operation Manual

-

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

Pad Printers Comprehensive upgrade ~ the price remains unchanged

-

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

Pad printer machine scraping ink is not clean, problem resolve

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links