Reference

Part-1 Screen Stencil-Screen Printing Knowledge

| Filename | Screen Printing Knowledge-Part-1 Screen Stencil.pdf |

| File Size | 235.7KB |

| Revision Date | 2023/01/30 |

Screen Printing Knowledge-Part-1 Screen Stencil

-

First of all, we’d like to introduce the dos and don’ts for cleaning a screen stencil.

-

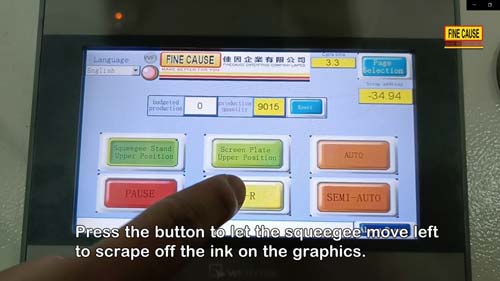

Before cleaning the screen stencil, the ink on the screen must be scraped off.

- Press the button on the screen printer to let the squeegee move left to scrape off the ink on the graphics.

-

If the squeegee is soft and there is still residual ink after scraping, a harder squeegee can be used to scrape off the ink manually.

-

Do we only have to wipe the bottom of screen with a cloth? Does the top need to be wiped?

-

Of course, wiping both top and bottom sides of the screen is the best and cleanest way to clean.

-

Notice:

-

Be careful when cleaning the screen stencil!(If we need to clean the screen stencil during printing).

-

Be gentle while cleaning the screen stencil.

-

Wet the cloth to the point where the solvent can be wrung out easily.

-

Do not use a cloth that is not wet enough to wipe the screen back and forth quickly.

-

Then wipe gently to prevent the thickness of graphics emulsion from thinning due to rubbing.

-

-

How do we confirm that the screen stencil is clean?

-

Use a magnifying glass to check if there is ink residue.

-

-

What if the graphics are too large to be checked one by one?

-

First, we need to use a clean cloth with cleaner or thinner slow.

-

The ink will block the screen mesh if it is not cleaned completely.

-

If the cloth becomes dirty, replace it with a new one.

-

-

Repeated wiping. Until the cloth is not stained with ink.

-

Do we have to use the Detergent to clean the screen stencil?

-

The cleaner has a very high volatility, which is convenient for rapid volatilization after cleaning.

-

If hardener is added in the ink, a thinner slow should be used to clean and remove the ink effectively.

-

After wiping, dry the thinner slow completely with a hair dryer under the screen stencil.

-

Use a hair dryer to dry. Then thinner slow solvent does not remain. Residual solvent will make printing 【blurred】.

-

Notice:

-

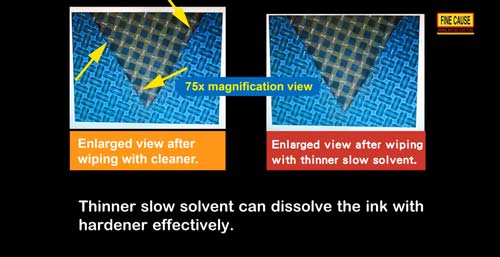

The residual ink is invisible to the naked eye.Use 2.5D vision measuring machine to see

-

Use 2.5D vision measuring machine to see the difference after cleaning.

-

Use 2.5 disambiguation vision measuring machine to see the difference after cleaning.

-

-

75x magnification view

-

-

Enlarged view after wiping with cleaner.

-

Enlarged view after wiping with thinner slow solvent.

-

-

Thinner slow solvent can dissolve the ink with hardener effectively.

-

Especially if the 【ink is added with hardener】, we should check the screen stencil carefully if the screen has been cleaned completely.

-

Otherwise, the ink will 【block the mesh】.

-

After the hardener 【reaction time is reached, the screen stencil will nt be cleaned completely】!

-

For fine graphic lines, a thoroughly cleaned screen is crucial.

-

Part 1- Screen Stencil Cleaning

Part 2- Screen printing machine Squeegee

Part 4- Screen Printer/ Screen Printing Machine

Which Silk Screen Printing Machine Should You Choose?

Please download the file if you need the complete content, please click the Download button to download.

Links

Links