Products

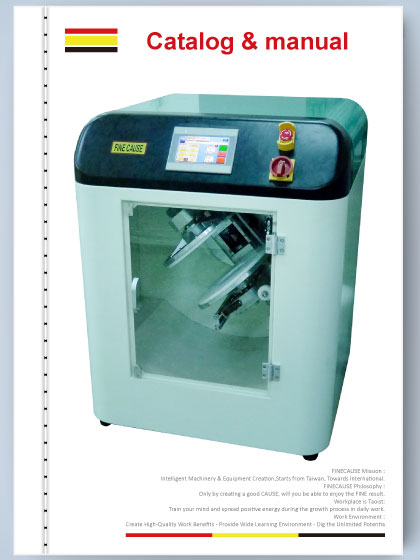

Vacuum Planetary Centrifugal Mixer/Planetary Centrifugal Mixer

Vacuum Planetary Centrifugal Mixer/Planetary Centrifugal Mixer

Product Info

▲A fully automatic centrifugal vacuum degassing mixer for faster processing and better results

Vacuum Planetary Centrifugal Mixer/Planetary Centrifugal Mixer-GMFC700VS-TW

Developed & Manufactured by FineCause

High-Efficiency Mixing × Vacuum Degassing × Precision Control

Product Overview — Centrifugal Degassing Mixer

Planetary centrifugal degassing mixers—also known as vacuum degassing mixers, planetary mixers, revolution-rotation mixers, non-contact mixers, and high-viscosity degassing mixers—combine high-speed revolution and rotation motions to achieve uniform dispersion and complete degassing in a short period of time.

The stable centrifugal force and vacuum-assisted system allow bubbles to escape quickly, ensuring optimal density, uniformity, and quality stability.

This model is ideal for processing high-viscosity and multi-phase materials commonly found in electronic pastes, nanomaterials, cosmetics, and battery slurries.

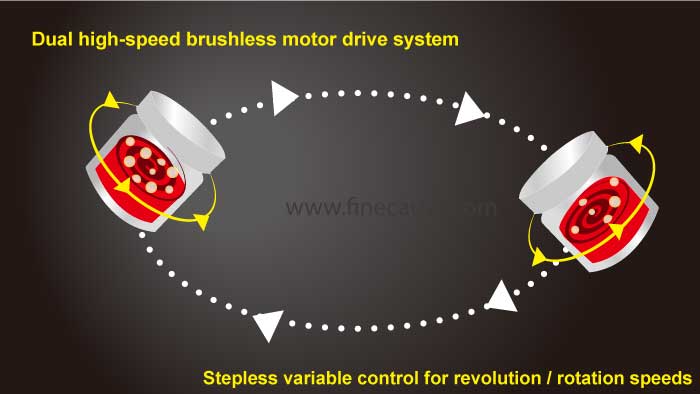

Operating Principles of the Vacuum Degassing Mixer (Revolution + Rotation + Degassing)

Revolution Principle

During operation, the containers revolve at high speed around the central axis, generating strong centrifugal force.

This centrifugal force pushes the materials outward while compressing them vertically through gravity and inertia, layering and redistributing the material.

This process efficiently drives out trapped air, achieving a thorough degassing effect. Because bubbles have the lowest density, they are forced out as higher-density materials move outward (toward the bottom) of the container during centrifugal motion. Lower-density components, such as air bubbles, are squeezed and separated. If only revolution is applied without rotation, the mixture will stratify according to density: higher-density materials will settle toward the bottom, layer by layer, while lower-density components will remain near the surface.

Rotation Principle

During operation, a 45-degree rotation is performed simultaneously with the revolution, causing the material inside the container to form a strong vortex flow. This angled rotational motion, combined with the revolution, applies forces from different directions, causing the material to flow in intersecting paths. As a result, even viscous or multi-component mixtures can be quickly blended and evenly dispersed.

By adjusting the revolution/rotation speed ratio, the mixer can be optimized for different material characteristics, ensuring stable and consistent mixing performance. Even high-viscosity substances or powder-liquid composites can be thoroughly integrated.

Vacuum Degassing Function

The vacuum degassing mixer is equipped with a vacuum pump, which can be activated when processing materials with very high viscosity to further enhance the degassing effect.

With this function, the final mixture can achieve a bubble-free and uniformly blended result.

Key Features of the Planetary Centrifugal Mixer

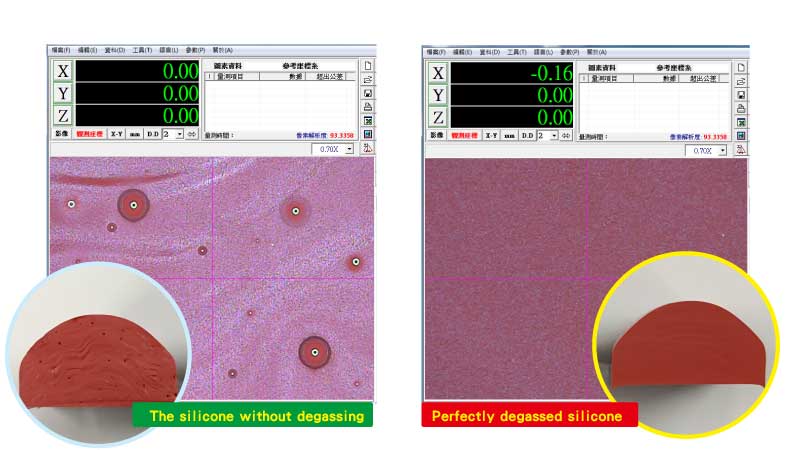

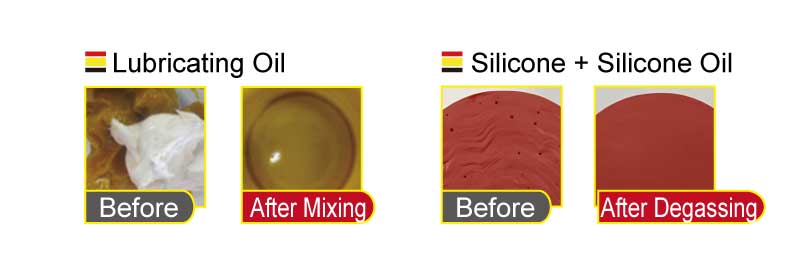

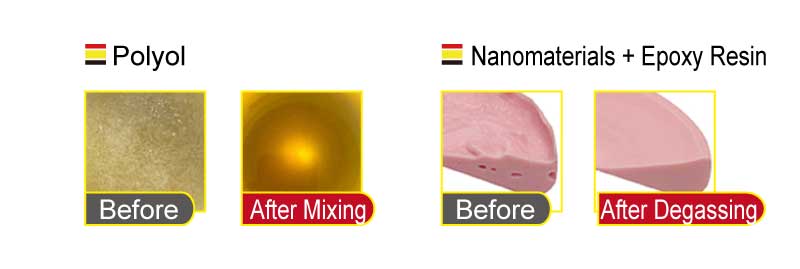

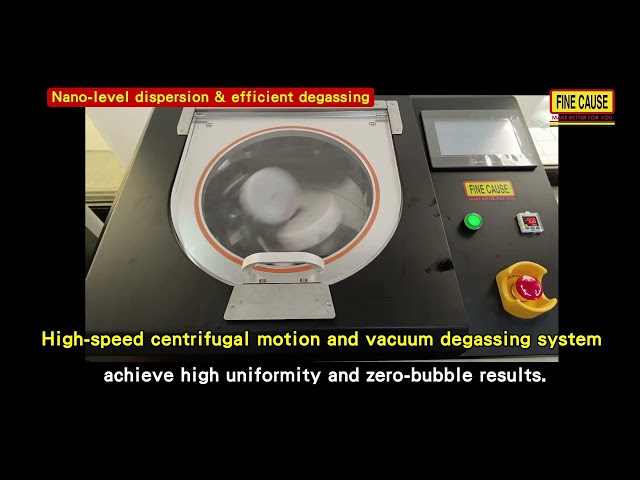

Nano-Level Dispersion & High-Efficiency Degassing

The combination of high-speed centrifugal mixing and vacuum degassing system delivers high uniformity and bubble-free results in a short time.

▲ Silicone + Silicone Oil – Before/After Mixing by Vacuum Degassing

▲ Cured silicone is inspected with a 2.5D measurement instrument to evaluate the defoaming performance.

Dual high-speed brushless motor drive system with stepless speed adjustment for both revolution and rotation

Revolution and rotation speeds can be freely set according to material characteristics, enhancing mixing efficiency and compatibility with different materials.

Dual-container design for flexible operation

Total volume: 700 mL × 2

Maximum filling volume: 500 mL per container (weight up to 700g)

Supports simultaneous processing of two containers, or single-container operation with a counterweight for flexible adjustment.

Mixing Modes (Single-parameter):

Allows setting a single revolution speed, time, rotation ratio, and vacuum level—ideal for simple mixing tasks.

Rotation can be set to Standard (forward) or Boost (reverse).

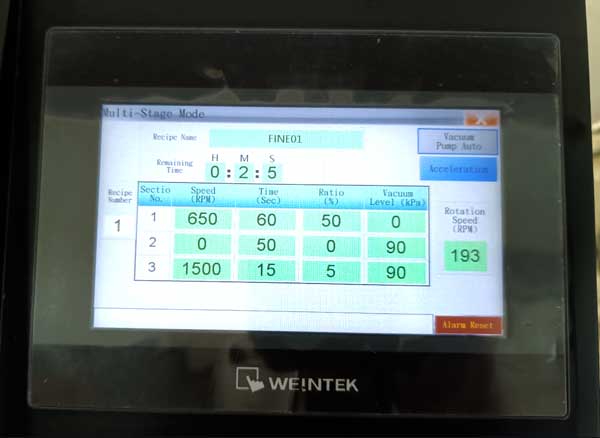

Multi-stage Mode (Multi-parameter):

Features 10-stage parameter settings (revolution speed, time, rotation ratio, vacuum level), enabling:

Pre-mixing: The first stage can be set to a lower speed for initial blending of multiple components.

Intensive Mixing: The middle stage can be set to a higher speed to achieve uniform mixing of multiple components.

Degassing Optimization: The final stage focuses on degassing, with revolution and rotation speeds slightly lower than those in the middle stage.

Rotation can be set to Standard (forward) or Boost (reverse).

This mode delivers combined effects of pre-mixing, high-power mixing, and degassing, and is generally the recommended option.

Recipe Memory Function

Users can customize recipe names and store up to 30 recipes, each with 10-stage settings, allowing quick switching and easy reproduction of production conditions.

Human–Machine Interface (HMI Touch Panel)

Equipped with an intuitive touch-screen interface for easy operation and quick learning. Supports switching between 5 languages: Traditional Chinese / English / Indonesian / Vietnamese / Thai.

Multiple Safety Protection System

Includes door-cover detection, vibration abnormality alerts, overload protection, emergency stop, and vacuum abnormality alarms to ensure comprehensive operational safety.

Applications of Planetary Centrifugal Vacuum Degassing Mixers

The GMFC700VS-TW centrifugal vacuum degassing mixer is widely used in:

Electronics Industry: Conductive adhesives, electronic pastes, dielectric pastes, anti-counterfeit inks, solar pastes.

Nanomaterials: Carbon nanotubes, graphene, nanocomposites, nano metal powders.

Cosmetics Manufacturing: Foundation, blush, lipstick, lip gloss, eyebrow pencils, eyeshadows, sunscreen, BB creams, nail polish, eyelash adhesives, etc.

New Energy Batteries: Lithium-ion, sodium-ion, fuel cells, solid-state batteries.

Food & Pharmaceutical: Syrups, chocolate, medical ointments, hyaluronic acid fillers, dental materials, orthopedic gels, etc.

Materials Suitable for Planetary Centrifugal Mixer

Compatible with a wide range of high-viscosity and precision-mixing materials:

Epoxy resin, polyurethane, silicone, electronic inks, conductive adhesives, colorants, pigments, carbon nanotubes, nano powders, composite materials, and more.

Key Advantages of the GMFC700VS-TW Vacuum Degassing Mixer

In-house R&D and manufacturing by FineCause, ensuring precise and stable construction

Dual brushless motor centrifugal mixing technology

Vacuum-assisted degassing system

Multi-stage recipe memory control

High-level safety protection with low maintenance cost

Specifications

| Model | GMFC700VS-TW Vacuum Planetary Centrifugal Mixer |

|---|---|

| Power Supply | Single-phase, AC220V, 50/60Hz |

| Operation Method | HMI touch panel |

| Machine Dimensions (cm) | L 73*W 51*H 79 cm |

| Configured Container Size | Capacity: 700 mL * 2 containers |

| Applicable Mixing Range | Actual material processing capacity: 500 mL * 2 containers |

| Maximum material processing weight: 700 g * 2 containers | |

| Supports simultaneous processing of two containers, or single-container operation with a counterweight. | |

| Speed | Revolution / rotation – stepless variable speed |

| Net Weight (kg) | 130 kg |

Videos

-

Automatic Gyroscopic Mixer

Automatic Gyroscopic Mixer

-

Fine Cause Prints Your Life

Fine Cause Prints Your Life

-

Mixing Machine / Blending Machine - Automatic 720° Gyroscopic Mixer-【GMFC30A-S-TW】

Mixing Machine / Blending Machine - Automatic 720° Gyroscopic Mixer-【GMFC30A-S-TW】

-

Planetary Centrifugal Mixer / Vacuum Degassing Mixer - GMFC700VS-TW

Planetary Centrifugal Mixer / Vacuum Degassing Mixer - GMFC700VS-TW

Downloads

-

How to Choose the Right Mixer? Rotary or Vibration?

How to Choose the Right Mixer? Rotary or Vibration?

How to Choose the Right Mixer? Rotary or Vibration?

-

GMFC30A-TW-Automatic Gyroscopic Mixer

GMFC30A-TW-Automatic Gyroscopic Mixer

GMFC30A-TW-Automatic Gyroscopic Mixer

-

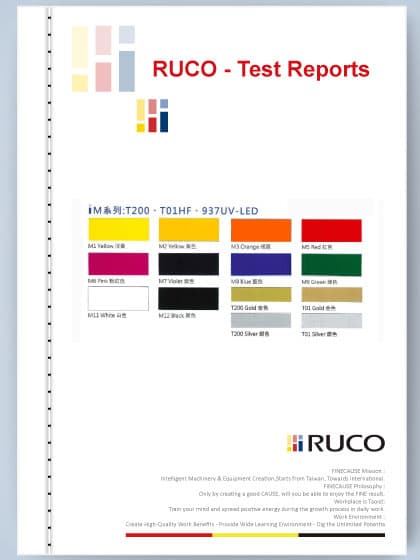

RoHS - 937LED

RoHS - 937LED

RoHS - 937LED

-

Toxikon Class VI Certificate - T200

Toxikon Class VI Certificate - T200

Toxikon Class VI Certificate - T200

-

MSDS_920UV_EN

MSDS_920UV_EN

MSDS_920UV_EN

-

MSDS_T01

MSDS_T01

MSDS_T01

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links