Products

Roller Transfer Hot Stamping Machine/Roll-on Hot Stamping Machine

Roller Transfer Hot Stamping Machine/Roll-on Hot Stamping Machine

Product Info

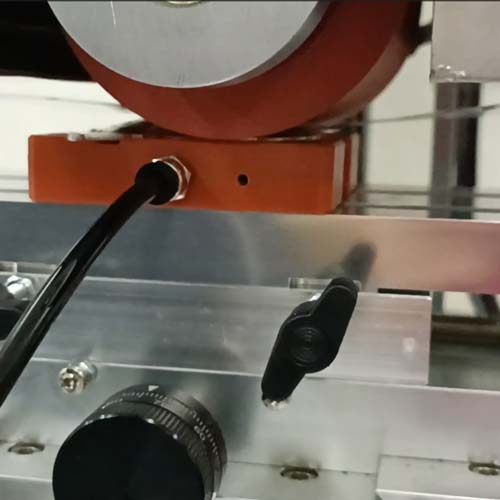

Roller Transfer Hot Stamping Machine/Roll-on Hot Stamping Machine-B001FCTM400T

Feature:

-

The heat transfer graphic area can be larger.

-

It is more acceptable of objects surfaces with high and low undulations.

-

The heat transfer foil film can be positioned using either 【photoelectric positioning】 or 【color sensor positioning】. The hologram security label can also be transferred.

-

The positioning accuracy for feeding is ±0.03mm.

-

-

The heat transfer press down height can be fine-tuned. A scale for checking press down height is provided.

-

The handwheel allows for extensive height adjustment.

-

Front and rear sliding table - object displacement mechanism: manual operation process is conducted away from the heating area, ensuring hands operate in a safe location.

-

7" 65536 color TFT touch screen:

-

Built-in 5 languages, traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

With I/O (input/output), each sensor location is shown in whole area of the machine.

-

An abnormal warning display allows production line personnel to quickly troubleshoot and resolve issues.

-

With electronic air pressure sensing system, the machine will stop and alarm automatically for insufficient air pressure.

-

The usage count of the silicone rubber roller is used can be set. While reaching the set value, the machine will stop automatically and notice.

-

The heat transferring temperature, time, etc. can be set and multiple sets of formulas can be stored. The parameters can be directly imported for the next production of the same product.

-

-

An air suction device can be installed according to the product requirements.

-

Adopt PLC, which is easy to add or modify functions.

-

With smart factory Industrial Internet of Things (I.O.T.), the roller transfer hot stamping machine is built-in smart bar chart that the productivity, operation time, production speed, etc in the past 30 days can be shown. Wherever you are, you can view the productivity report by downloading the FineCause APP.

■The main advantages of a thermal transfer machine with film roller (film Roller Transfer Hot Stamping Machine) are as follows:

-

Printing Quality: The film Roller Transfer Hot Stamping Machine can achieve high-quality printing results, especially excelling in handling fine details and color transitions. It can print on various materials such as textiles, leather, plastics, glass, ensuring long-lasting and durable printing quality.

-

Versatility with Multiple Materials: This machine is suitable for a wide range of materials, making it highly versatile in various applications. It can effortlessly print on flat materials as well as handle curved and irregularly shaped materials, catering to different industries and product needs.

-

Environmentally Friendly: Compared to other printing techniques, the film Roller Transfer Hot Stamping Machine requires less use of chemicals or solvents during the process, making it more environmentally friendly. Moreover, products printed using this method are easier to recycle.

-

High Production Efficiency: The film Roller Transfer Hot Stamping Machine allows for continuous printing, resulting in higher production efficiency. It is well-suited for large-scale production, saving time and labor costs.

-

Scratch Resistance: Prints and texts produced using the film roller thermal transfer technology have strong scratch resistance, making them less prone to fading and wear. This results in longer product lifespans.

-

In conclusion, the film Roller Transfer Hot Stamping Machine has significant advantages in printing quality, versatility with materials, environmental friendliness, production efficiency, and product durability. It is particularly suitable for applications that require high-quality and long-lasting printing effects.

A: Are the film Roller Transfer Hot Stamping Machine and the drum thermal transfer machine the same type of equipment?

B: The film Roller Transfer Hot Stamping Machine and the drum thermal transfer machine are not the same type of equipment; they are two different thermal transfer printing technologies.

-

The film Roller Transfer Hot Stamping Machine is a thermal transfer technology that uses a film or foil as a medium to transfer patterns or images onto the surface of materials. Its working principle involves printing the desired patterns onto the film and then transferring them onto the material through the application of heat and pressure.

-

On the other hand, the drum thermal transfer machine, also known as flexographic thermal transfer machine, is another type of thermal transfer technology. It uses a flexible printing plate as a medium to transfer patterns or images onto the material's surface. In this method, the patterns on the printing plate are heated and then come into contact with the material's surface, transferring the ink onto it.

-

While both the film Roller Transfer Hot Stamping Machine and the drum thermal transfer machine are forms of thermal transfer printing, their working principles and medium used are different. Hence, they are not the same type of equipment; they represent two distinct thermal transfer printing technologies. Each technique has its suitable application scenarios and advantages, depending on the desired printing effects and material characteristics.

Specifications

| Model: | B001FCTM400T |

|---|---|

| Roller size: | 100 dia.×110 L |

| Voltage: | 220V 50/60HZ |

| Platform: | 100×220L |

| Heaters: | 500W×4PCS |

| Max. opening: | 400mm |

| Foil rolling: | Variable-speed motor, photocell, and timer |

| Foil releasing: | Torque limiter |

| Machine size: | 900×780×1900mm |

| Machine weight: | 255kg |

Videos

-

Hot Transfer Printing Machine (Hot Stamping / Bronzing)-FABM200T-CJ

Hot Transfer Printing Machine (Hot Stamping / Bronzing)-FABM200T-CJ

-

FABM01-Hot Stamping Machine /Bronzing Machine

FABM01-Hot Stamping Machine /Bronzing Machine

-

leather handbook that was branded with a hot stamping machine

leather handbook that was branded with a hot stamping machine

-

Roller Transfer Hot Stamping Machine/Roll-on Hot Stamping Machine-B001FCTM400T

Roller Transfer Hot Stamping Machine/Roll-on Hot Stamping Machine-B001FCTM400T

-

Heat transfer printing machine/Hot stamping machine/Flat Heat transfer printer-FABM300TM-JM

Heat transfer printing machine/Hot stamping machine/Flat Heat transfer printer-FABM300TM-JM

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links