Products

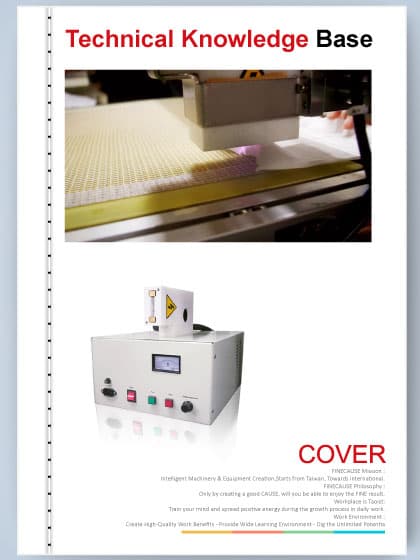

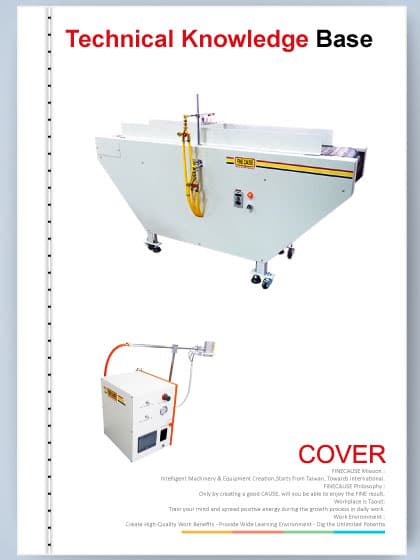

Rotary Plasma Surface Treatment Machine (Flat and Curved Shapes Shared - Servo)

Rotary Plasma Surface Treatment Machine (Flat and Curved Shapes Shared - Servo)

Product Info

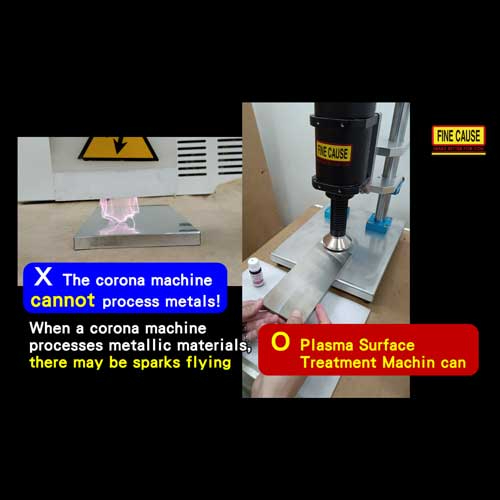

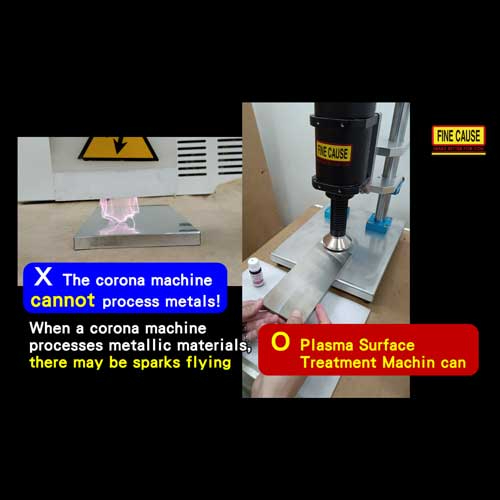

Difference between plasma machine and corona machine

The corona machine cannot process metals!

When a corona machine processes metallic materials, there may be sparks flying, which is more dangerous and can cause damage to the metal materials.

Metallic material surface treatment requires the use of a plasma treatment machine.

Advantages of plasma treatment machine:

Plasma treater surface treatment: Suitable for various materials including metal, ceramic, glass, PVC, paper, and plastic.

Functions include:

-

1. Significantly improves the wetting performance of the surface, forming an active surface.

-

2. Remove dust and oil stains, finely clean and remove static electricity.

-

3. Improve the adhesion ability of the printing surface.

FAFP02-SLG Rotary Plasma Surface Treatment Machine (Flat and Curved Shapes Shared - Servo)

Features, main configuration, and advantages:

Servo sliding table and servo rotating mechanism

-

Supports flexible settings: Precise digital settings through the HMI.

-

Cylindrical bottles: 1. Preparation angle, 2. Start processing angle, 3. End processing angle, 4. Rotating speed, 5. Rotation processing times/cycles, 6. CW and CCW rotation selection

-

-

Regular polygon bottles: 1. Preparation position, 2. Start processing position, 3. End processing position, 4. Lateral processing speed, 5. Processing count, 6. Number of sides

-

Can process various bottle shapes, including cylindrical bottles, rectangular bottles, and regular polygon bottles (such as square, pentagon, etc.), and can also perform single-side processing.

-

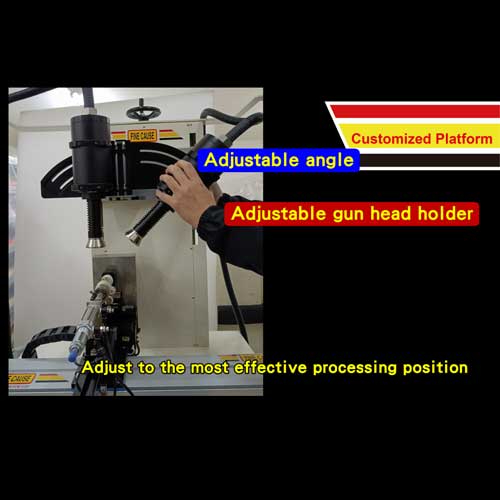

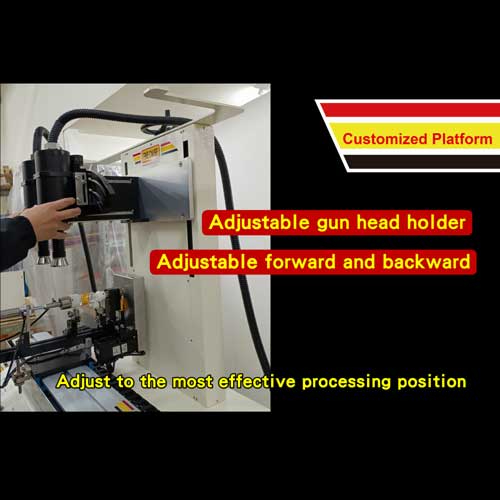

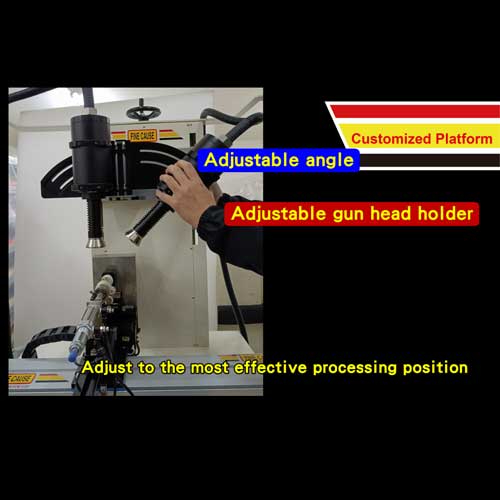

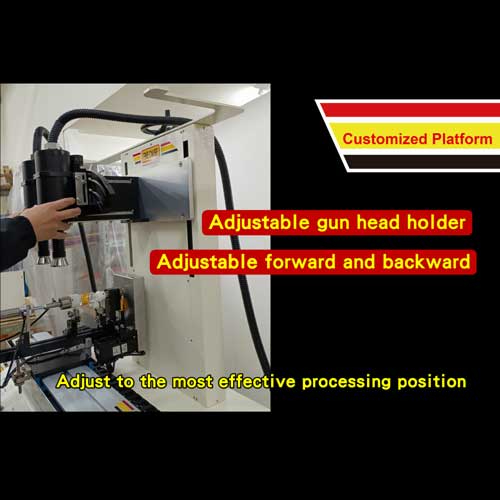

Adjustable gun head holder

- Adjustment range includes: 1. Angle, 2. Height, 3. Forward and backward position, adjusted to the most effective processing position.

Handwheel adjustment of nozzle height

- Suitable for containers of different sizes, with precise adjustment of the processing position.

Jig with bottle clamping cylinder device

- The horizontal adjustment mechanism ensures the container is securely fixed and guarantees efficient handling of the maximum surface area.

o Includes: 1. Round bottle jig, 2. Square bottle jig.

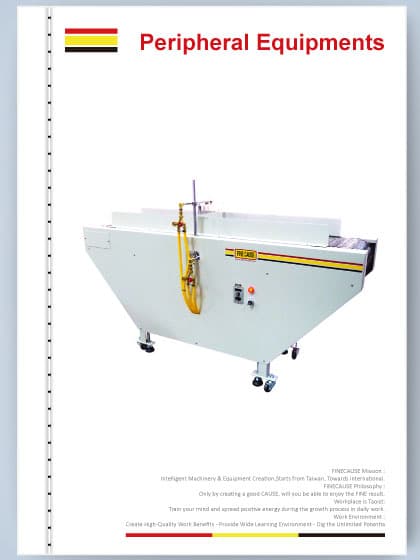

Dual-side plasma machine frame

- The machine is equipped with wheels for easy movement between production lines.

PLC system and HMI

-

Supports multiple languages: Traditional Chinese, English, Indonesian, Vietnamese, and Thai.

-

Equipped with a formula memory function, allowing for preset processing parameters for various materials, simplifying the operation process, and enabling quick switching between different materials with one click.

Specifications

| Model | FAFP02-SLG |

|---|---|

| Supply Voltage | 220 VAC,50/60Hz |

| Power Input Fuse | 10A/250V |

| Operating Frequency | 18KHz ~ 60KHz |

| Working High Voltage | 2KV ~ 10KV |

| Maximum Practical Output Power | 1000W (Based on actual situation) |

| Working Pressure Range | About 0.2MPa ~ 0.3MPa (2Kg ~ 3Kg) |

| Air Source Requirements | ≥0.3Mpa(3Kg), <1MPa (10Kg), Oil free and water free |

| Overall Machine Dimensions | 140*83*170cm |

| Mechanism | Servo Rotating |

| Servo Sliding Table | |

| Bottle Pushing | |

| Multi-Stage Adjustable Gun Head Holder | |

| Touch Panel | 7.0-Inch TFT Color Touch Screen |

| Total Weight | 240 Kg |

Videos

-

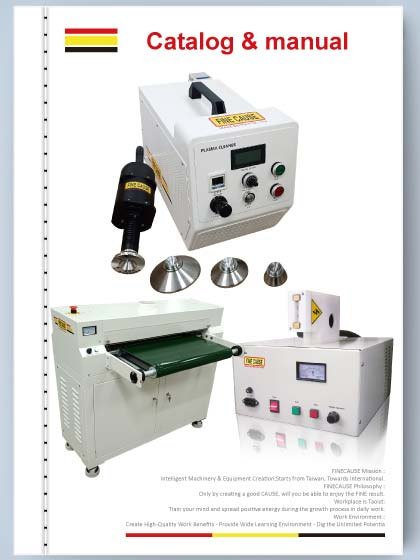

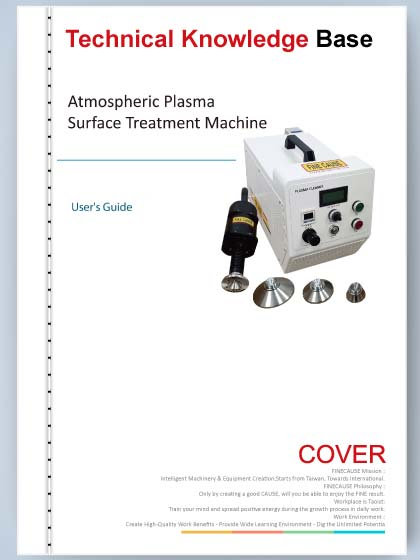

Plasma Surface Treatment Machine (Rotating Gun) Installation Tutorial-【F1Z-1000】

Plasma Surface Treatment Machine (Rotating Gun) Installation Tutorial-【F1Z-1000】

-

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

-

FAFP01-Flame (corona) Treatment Machine-plasma treatment for plane and cylindrical

FAFP01-Flame (corona) Treatment Machine-plasma treatment for plane and cylindrical

-

Corona Machine - User Instruction

Corona Machine - User Instruction

-

Rotary Plasma Surface Treatment Machine (Flat and Curved Shapes Shared - Servo)-【FAFP02-SLG】

Rotary Plasma Surface Treatment Machine (Flat and Curved Shapes Shared - Servo)-【FAFP02-SLG】

Downloads

-

How to Choose Between a Plasma Treatment Machine and a Corona Treatment Machine?

How to Choose Between a Plasma Treatment Machine and a Corona Treatment Machine?

How to Choose Between a Plasma Treatment Machine and a Corona Treatment Machine?

-

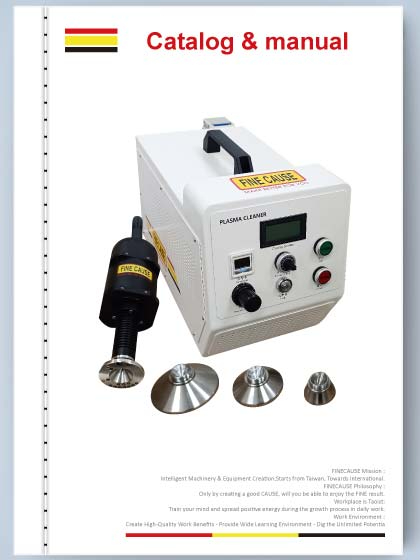

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

Plasma Surface Treatment Machine (Rotating Gun)-F1Z-1000

-

Plasma Surface Treatment Machine (Rotating Gun) manual

Plasma Surface Treatment Machine (Rotating Gun) manual

Plasma Surface Treatment Machine (Rotating Gun) manual

-

Corona Treatment

Corona Treatment

Corona Treatment

-

Flame Treatment Related Knowledge

Flame Treatment Related Knowledge

Flame Treatment Related Knowledge

-

Flame Treatment machine

Flame Treatment machine

Flame Treatment machine

RFQ form

Thank you for your query, Our specialist will contact you soon.

Links

Links