Reference

Flame Treatment Related Knowledge

| Filename | Flame Treatment Related Knowledge.docx |

| File Size | 81.2KB |

| Revision Date | 2020/08/26 |

Flame Treatment Related Knowledge

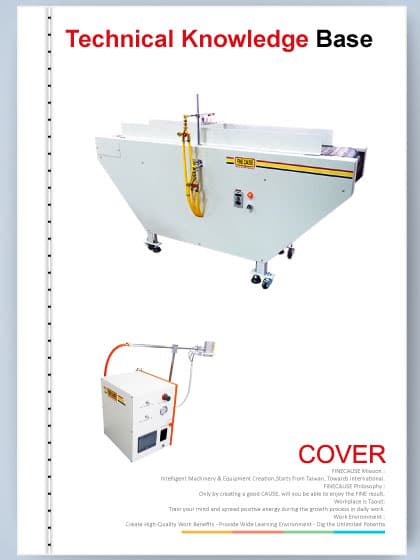

Flame treatment :

At present, the light curing ink has not been directly used untreated PE、PP bottles.

Therefore, to print PE and PP bottles, the PP and PP must be polarized before printing, otherwise the UV ink cannot be firmly attached.

So how to deal with?

There are several methods of polarization treatment . In PE, PP plastic and bottles, most of them are treated by flame.

The result of this flame treatment is use of free radicals such as O、N0、OH and NH in the flame.

It can extract the surface oxygen of high polymers such as PE PP etc., and then perform surface oxidation according to the free radical mechanism, in addition, some polar oxygen-containing groups are introduced to undergo chain scission reaction, and the non-polar PE and PP are polarized to change the wettability of surface and ensure the adhesion of the ink.

The above is only a partial preview, please download the file if you need the complete content, please click the Download button to download.

Links

Links